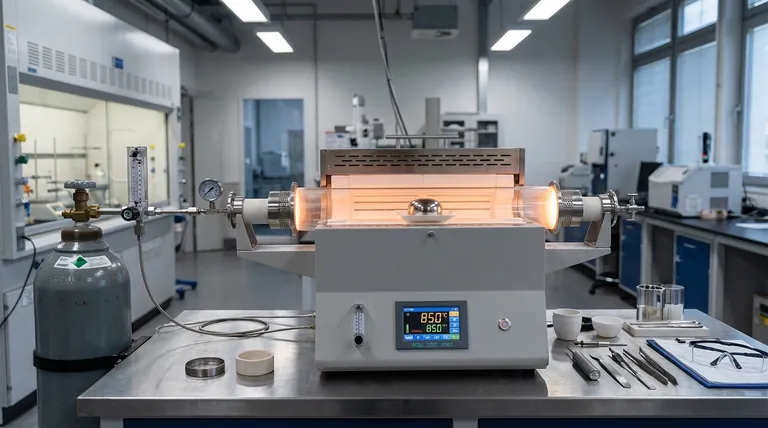

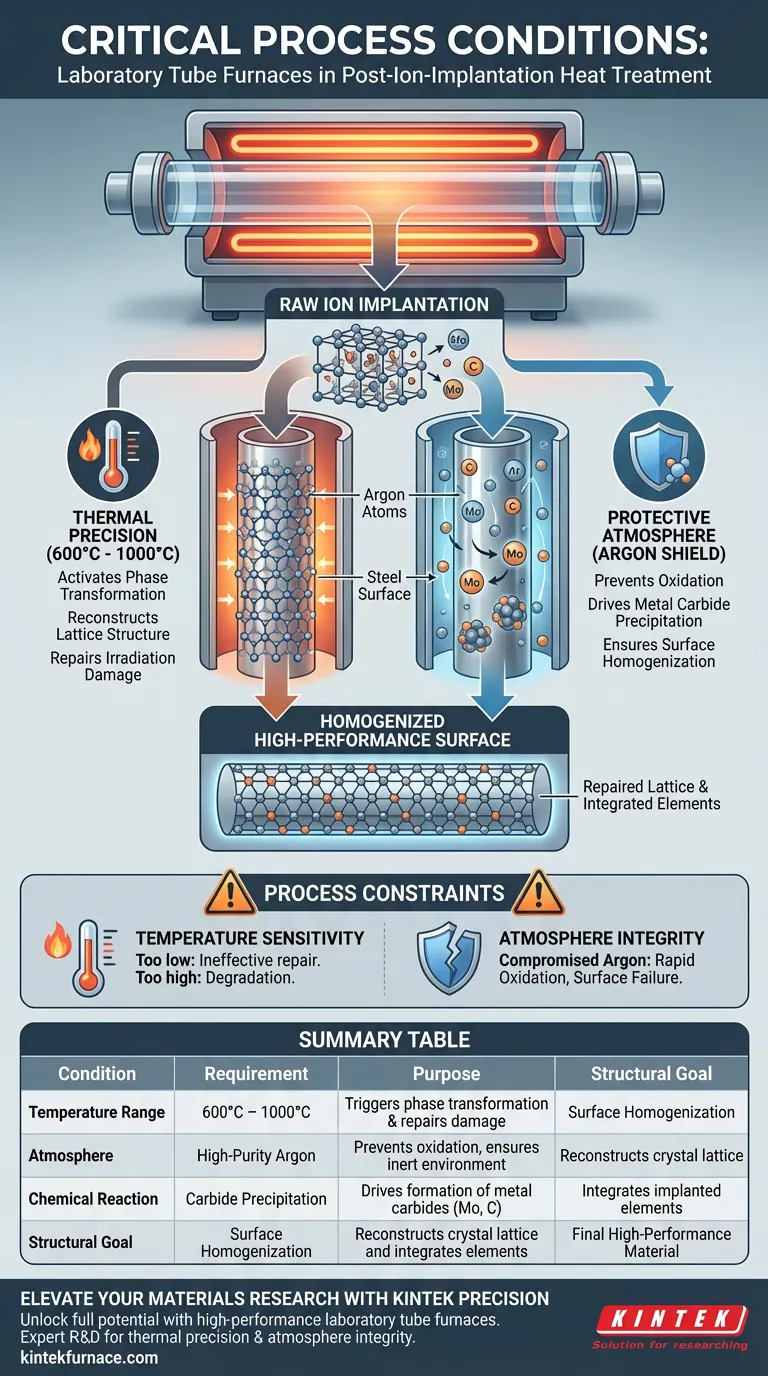

A laboratory tube furnace provides a strictly controlled, inert high-temperature environment designed to stabilize stainless steel following ion implantation. Specifically, it establishes a precise temperature regime between 600°C and 1000°C while maintaining a protective argon atmosphere to facilitate critical microstructural repairs.

The furnace is not simply a heating source; it acts as a reaction chamber that repairs irradiation damage and drives the precipitation of metal carbides. This controlled environment is the bridge between raw ion implantation and a homogenized, high-performance material surface.

The Critical Role of Thermal Precision

Activating Phase Transformation

The primary function of the tube furnace is to maintain a specific thermal window, strictly between 600°C and 1000°C. This high-temperature range is not arbitrary; it is the required energy threshold to trigger phase transformation within the steel.

Reconstructing the Lattice Structure

Ion implantation is a violent process that introduces foreign elements—specifically molybdenum and carbon in this context—into the steel, disrupting its crystal lattice. The heat treatment provided by the furnace supplies the activation energy needed for structural reconstruction.

Repairing Irradiation Damage

Beyond simple heating, this thermal environment allows the material to heal. The sustained high temperature repairs the irradiation damage caused during the initial implantation process, restoring the integrity of the stainless steel matrix.

The Necessity of a Protective Atmosphere

The Argon Shield

A defining feature of this process is the maintenance of an argon protective atmosphere. The tube furnace design allows for the exclusion of oxygen and other reactive gases during the heating cycle.

Driving Carbide Precipitation

Under this inert protection, the injected elements are free to react chemically in beneficial ways without oxidizing. The environment facilitates the specific precipitation of metal carbides, which is the ultimate goal of the doping process.

Achieving Surface Homogenization

The combination of heat and inert gas allows for diffusion without degradation. This leads to surface homogenization, ensuring that the implanted elements are evenly distributed and fully integrated into the material's surface structure.

Understanding the Process Constraints

The Temperature-Window Sensitivity

Operating outside the 600°C to 1000°C range compromises the treatment's efficacy. Temperatures too low may fail to induce the necessary phase transformations or repair lattice damage, leaving the material in a stressed state.

Atmosphere Integrity

The success of the treatment relies entirely on the purity of the environment. If the argon atmosphere is compromised, the high temperatures will lead to rapid oxidation rather than the desired carbide precipitation, potentially ruining the surface enhancement.

Optimizing Your Heat Treatment Strategy

To ensure the success of post-ion-implantation annealing, your process parameters must align with the specific material goals of the project.

- If your primary focus is Structural Repair: Prioritize maintaining the temperature strictly within the 600°C–1000°C window to ensure adequate energy for lattice reconstruction and damage healing.

- If your primary focus is Surface Hardening: Ensure the argon flow is consistent and pure to maximize the precipitation of metal carbides without introducing surface contaminants.

By rigorously controlling these thermal and atmospheric variables, you convert the potential of ion implantation into realized material performance.

Summary Table:

| Process Condition | Requirement | Purpose in Heat Treatment |

|---|---|---|

| Temperature Range | 600°C – 1000°C | Triggers phase transformation & repairs irradiation damage |

| Atmosphere | High-Purity Argon | Prevents oxidation and ensures inert protective environment |

| Chemical Reaction | Carbide Precipitation | Drives the formation of metal carbides (Mo, C) for hardening |

| Structural Goal | Surface Homogenization | Reconstructs crystal lattice and integrates implanted elements |

Elevate Your Materials Research with KINTEK Precision

Unlock the full potential of your post-ion-implantation processes with KINTEK’s high-performance laboratory tube furnaces. Backed by expert R&D and world-class manufacturing, we provide the thermal precision and atmosphere integrity required to achieve superior surface homogenization and lattice repair.

Whether you need standard or fully customizable Tube, Muffle, Rotary, Vacuum, or CVD systems, KINTEK delivers the reliability your lab demands.

Ready to optimize your heat treatment results? Contact our experts today to find the perfect high-temperature solution for your unique needs!

Visual Guide

References

- Ruijuan Wang, Chengfei Zhu. Ion Implantation Combined with Heat Treatment Enables Excellent Conductivity and Corrosion Resistance of Stainless Steel Bipolar Plates for Hydrogen Fuel Cells. DOI: 10.3390/ma17040779

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the applications of an atmosphere tube furnace? Unlock Precise Material Processing

- How do vacuum tube furnaces contribute to environmental protection and energy production? Discover Their Role in Clean Tech

- How does the gas control system of a tube furnace contribute to the transformation of Ni-MOF into NiO/Ni@C?

- What are the applications of a laboratory tube furnace in chemical research? Unlock Precise High-Temperature Synthesis

- How does a multi-tube pyrolysis furnace achieve precise temperature control? Advanced Hardware & PID Logic Explained

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing

- How does a tube furnace facilitate the growth of controlled oxide layers on X70 carbon steel? Engineering Precision

- Why is a long-term annealing process in a tube furnace essential for Bi-Sb alloy? Achieve Material Homogeneity