In chemical research, a laboratory tube furnace is primarily used for high-temperature material synthesis, thermal analysis, and thin-film deposition. Its core function is to heat small samples to precise temperatures within a tightly controlled atmospheric environment, enabling processes like Chemical Vapor Deposition (CVD), catalyst evaluation, thermal decomposition, calcination, and annealing.

The true value of a tube furnace isn't just its ability to get hot; it's the power to create a highly specific, isolated environment. This precise control over both temperature and atmosphere is what allows researchers to synthesize novel materials and study chemical reactions at a fundamental level.

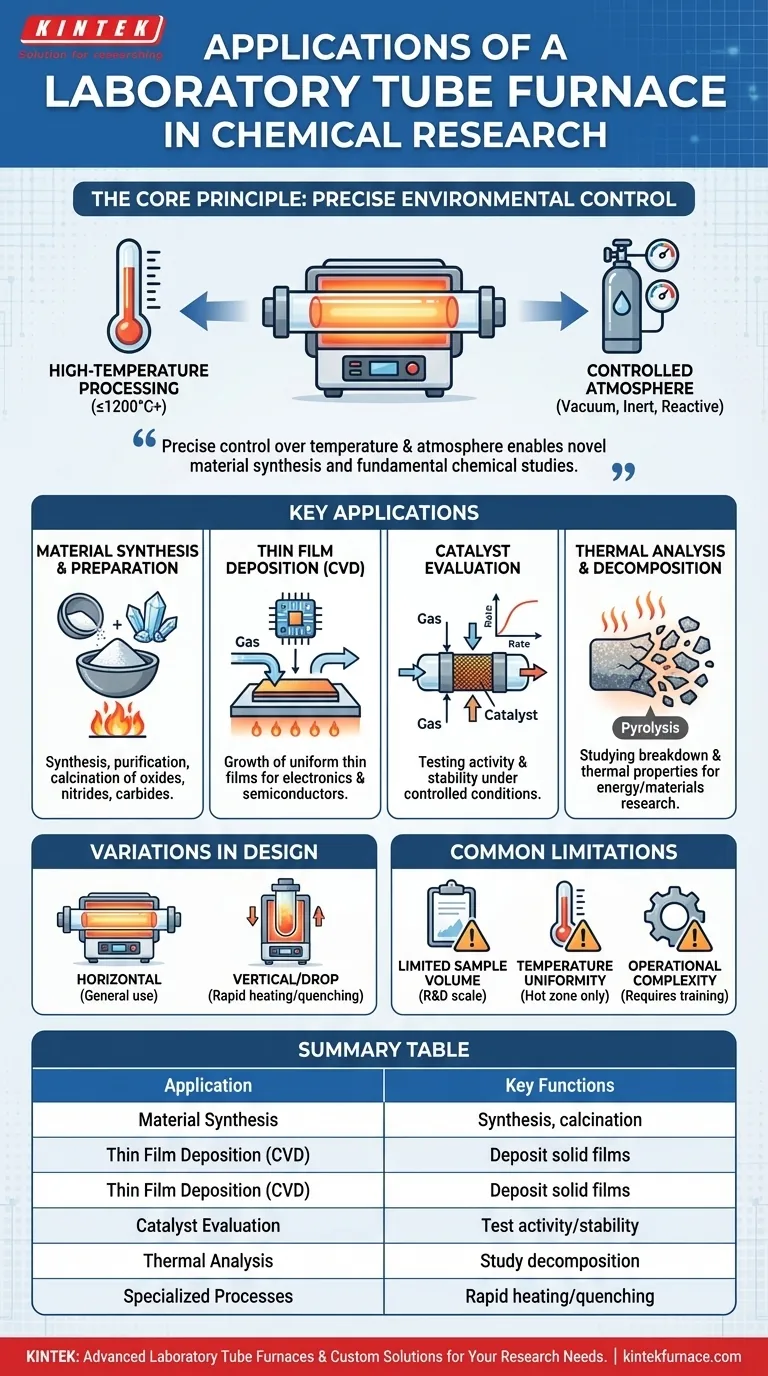

The Core Principle: Precise Environmental Control

A tube furnace's utility stems from its unique design: a heating chamber built around a central tube, typically made of ceramic or quartz. This setup provides unparalleled control over the two most critical variables in materials chemistry.

High-Temperature Processing

The furnace's heating elements can achieve extremely high and stable temperatures, often exceeding 1200°C. This is essential for reactions that require significant thermal energy, such as synthesizing crystalline materials or studying the thermal stability of compounds.

Controlled Atmosphere

The sealed tube allows researchers to dictate the exact gaseous environment surrounding the sample. This can be a vacuum, an inert gas like argon to prevent unwanted reactions, or a specific reactive gas that is part of the chemical process itself.

Key Applications in Chemical Research

By mastering temperature and atmosphere, a tube furnace enables a wide range of critical research applications.

Material Synthesis and Preparation

Tube furnaces are workhorses for creating new inorganic materials. This includes synthesis, purification, and calcination (heating to high temperatures in air or oxygen). Researchers use them to prepare specific forms of oxides, nitrides, carbides, and other advanced compounds.

Thin Film Deposition (CVD)

In Chemical Vapor Deposition (CVD), a volatile precursor gas flows through the heated tube. The high temperature causes the gas to react and deposit a solid, ultra-thin film onto a substrate placed inside. This is a fundamental technique for the semiconductor and electronics industries.

Catalyst Evaluation

Researchers test the activity and stability of catalyst materials by passing a reactant gas over the catalyst bed inside the furnace. By precisely controlling the temperature and gas flow, they can measure reaction rates and determine how well the catalyst performs under different conditions.

Thermal Analysis and Decomposition

Processes like pyrolysis (thermal decomposition in an inert atmosphere) are used to study how materials break down at high temperatures. This is vital for energy research involving biomass or coal, as well as for understanding the thermal properties of polymers and composites.

Understanding Variations in Furnace Design

Not all tube furnaces are the same. The orientation of the tube can be optimized for specific experimental needs.

Horizontal Furnaces

This is the most common configuration, ideal for static samples, CVD, and general thermal processing where the sample is placed in a crucible or on a substrate.

Vertical and Drop Tube Furnaces

Vertical furnaces are suited for processes requiring rapid heating or cooling, such as gas quenching tests. They are also used when a sample needs to be dropped from a cool zone into the hot zone to initiate a reaction, which is useful for studying combustion or certain types of crystal growth.

Common Pitfalls and Limitations

While powerful, a tube furnace is a specialized tool with inherent trade-offs that are important to understand.

Limited Sample Volume

Tube furnaces are designed for research and development, not mass production. The diameter of the tube restricts the size and volume of the sample that can be processed at one time.

Temperature Uniformity

The temperature is not perfectly uniform along the entire length of the tube. There is a central "hot zone" where the temperature is most stable and accurate. Placing samples outside this zone can lead to inconsistent results.

Operational Complexity

Achieving a truly controlled environment requires careful setup. Managing gas flow rates, ensuring leak-proof seals, and programming precise temperature ramps can be complex and requires proper training.

Making the Right Choice for Your Research

To leverage a tube furnace effectively, align its capabilities with your primary experimental goal.

- If your primary focus is creating new powders or crystalline materials: Use the furnace for synthesis, calcination, or annealing under specific atmospheric conditions.

- If your primary focus is surface engineering or electronics: The key application is Chemical Vapor Deposition (CVD) to grow uniform thin films.

- If your primary focus is studying reaction kinetics or material stability: Use it for catalyst evaluation or thermal decomposition studies like pyrolysis.

- If your primary focus is mimicking rapid industrial processes: A vertical or drop tube furnace is ideal for quenching or flash pyrolysis experiments.

Ultimately, the laboratory tube furnace is a cornerstone of modern materials science, providing the controlled window needed to build and understand materials from the atom up.

Summary Table:

| Application | Key Functions |

|---|---|

| Material Synthesis | Synthesis, purification, calcination of oxides, nitrides, carbides |

| Thin Film Deposition (CVD) | Deposits solid films for electronics and semiconductors |

| Catalyst Evaluation | Tests activity and stability under controlled conditions |

| Thermal Analysis | Studies decomposition via pyrolysis for energy and materials research |

| Specialized Processes | Uses vertical/drop furnaces for rapid heating or quenching experiments |

Ready to enhance your chemical research with precise high-temperature control? KINTEK specializes in advanced laboratory tube furnaces, offering Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our strong R&D and in-house manufacturing, we provide deep customization to meet your unique experimental needs—whether for material synthesis, thin-film deposition, or catalyst studies. Contact us today to discuss how our solutions can optimize your lab's performance and accelerate your discoveries!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents