In essence, an atmosphere tube furnace is a specialized piece of high-temperature equipment whose applications span materials science, advanced manufacturing, and industrial research. It is used for processes like the heat treatment of metals, sintering of ceramics and powders, development of new energy materials, and the manufacturing of semiconductors and solar cells. Its defining feature is the ability to perform these tasks within a precisely controlled gaseous environment.

The true value of an atmosphere tube furnace is not just its ability to generate high heat, but its power to control the chemical environment at that heat. This prevents unwanted reactions like oxidation and enables specific material transformations that would be impossible in open air.

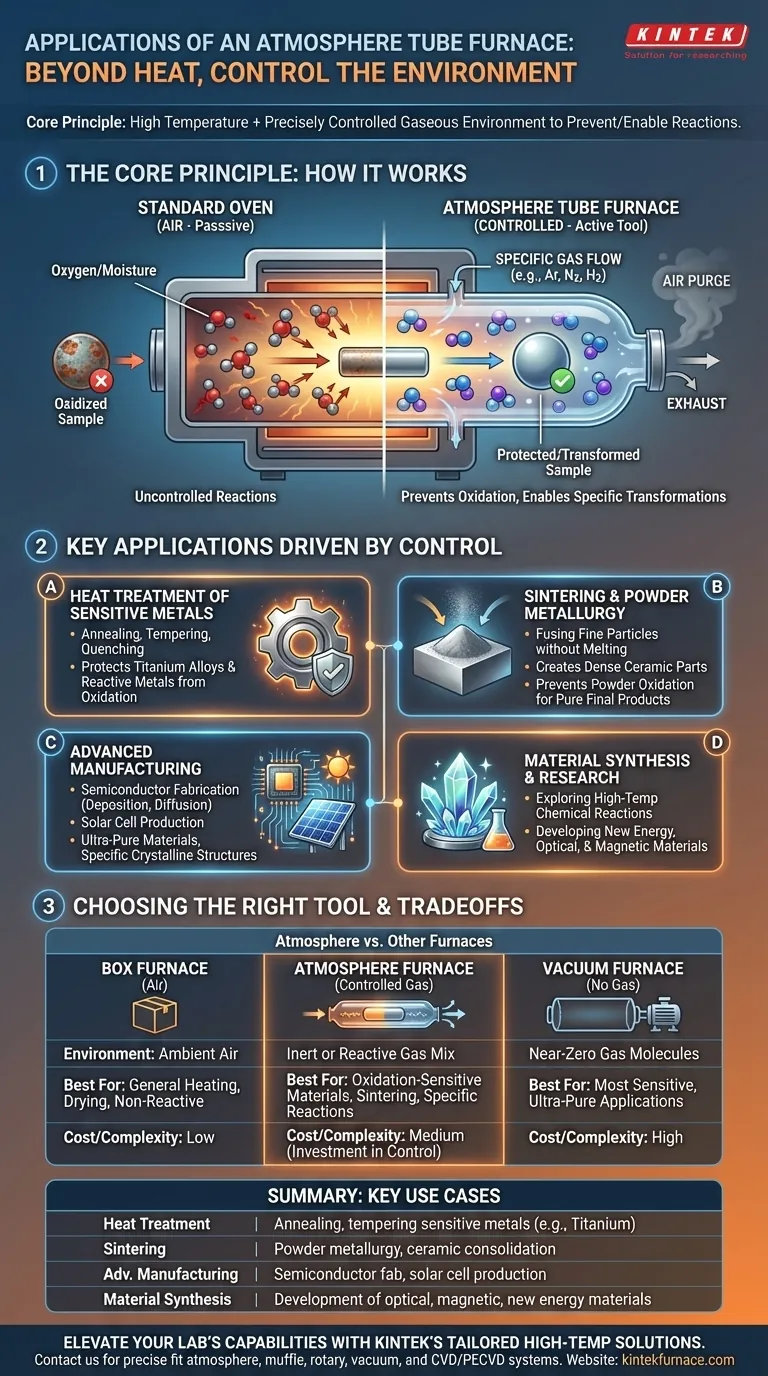

The Core Principle: Beyond Heat, It's About Atmosphere Control

An atmosphere tube furnace is fundamentally different from a standard oven or box furnace. Its primary advantage lies in its ability to manipulate the gas surrounding the workpiece, turning the atmosphere from a passive condition into an active tool.

What is a Controlled Atmosphere?

A controlled atmosphere is a specific mix of gases, intentionally introduced into the furnace tube to achieve a desired chemical reaction or prevent an undesirable one. This environment can be inert (using gases like argon or nitrogen to prevent any reaction) or reactive (using gases like hydrogen for reduction or other specific gases to participate in a chemical process).

How It Works: Regulating the Process Environment

The furnace works by first sealing a process tube (typically made of quartz, alumina, or ceramic) that contains the material sample. Before and during heating, specific gases are flowed through this tube, purging the ambient air. By precisely managing the type and flow rate of these gases, an operator can create a stable, non-oxidizing, or reducing environment critical for sensitive materials.

The Benefit of Precision

This level of environmental control is essential for modern materials science. It ensures that the properties of the material being processed are a direct result of the intended thermal cycle, not random reactions with oxygen or moisture in the air. This repeatability is non-negotiable for research and high-tech manufacturing.

Key Applications Driven by Atmospheric Control

The ability to control the furnace's atmosphere unlocks a wide range of applications that are impossible with simpler heating equipment.

Heat Treatment of Sensitive Metals

Many advanced metals, such as titanium alloys, are highly reactive with oxygen at high temperatures. Heating them in a standard furnace would cause immediate oxidation, compromising their structural integrity. An atmosphere furnace uses an inert gas to protect the metal during processes like annealing (softening), tempering, and quenching.

Sintering and Powder Metallurgy

Sintering is the process of fusing fine particles together using heat, without melting them. It is used to create dense ceramic parts and consolidate metal powders. A controlled atmosphere is critical to prevent the high-surface-area powders from oxidizing, ensuring a pure, strong final product.

Advanced Manufacturing Processes

Fields like semiconductor fabrication and solar cell production rely on creating ultra-pure materials with specific crystalline structures. An atmosphere furnace provides the clean, controlled environment needed for processes like deposition and diffusion, where even trace amounts of contaminants can ruin a component.

Material Synthesis and Research

For scientists developing new materials, the furnace is an indispensable tool. It allows for the exploration of high-temperature chemical reactions in a controlled setting, which is fundamental to creating novel optical materials, magnetic materials, and materials for the new energy sector.

Understanding the Trade-offs: Atmosphere vs. Other Furnaces

Choosing the right furnace depends entirely on whether the atmosphere is a critical process variable for your task.

Atmosphere Furnace vs. Box Furnace

A box furnace is a general-purpose workhorse for heating samples in ambient air. It is simpler, less expensive, and ideal for basic applications like drying, ashing, or heat-treating non-reactive materials. An atmosphere furnace is a specialized instrument for when the chemical environment must be strictly controlled.

Atmosphere Furnace vs. Vacuum Furnace

A vacuum furnace represents the next level of atmospheric control, creating an environment by removing nearly all gas molecules. While necessary for the most sensitive applications, vacuum systems are significantly more expensive and complex. An atmosphere furnace offers a more cost-effective solution for the vast majority of processes that simply require the exclusion of oxygen or the presence of a specific reactive gas.

The Cost of Control

The added complexity of gas handling systems, seals, and monitoring equipment makes an atmosphere furnace a greater investment than a simple box furnace. It requires more operational expertise to manage gas flows and ensure a properly sealed environment.

Making the Right Choice for Your Process

Your decision should be guided by the specific requirements of your material and process goal.

- If your primary focus is general-purpose heat treatment or lab sample heating: A simpler, more cost-effective box furnace is likely sufficient for your needs.

- If your primary focus is processing oxidation-sensitive materials like titanium or specific metal powders: An atmosphere furnace is essential to protect your material and achieve the desired outcome.

- If your primary focus is high-purity semiconductor or advanced materials research: You need the precise environmental control of an atmosphere furnace to ensure repeatable, reliable results.

- If your primary focus is cost reduction but you still need environmental control: An atmosphere furnace provides a powerful, more accessible alternative to a more complex and expensive vacuum furnace.

Ultimately, selecting an atmosphere furnace is a decision to treat the surrounding environment not as a background condition, but as a critical ingredient in your process.

Summary Table:

| Application | Key Use Cases |

|---|---|

| Heat Treatment | Annealing, tempering of sensitive metals like titanium alloys |

| Sintering | Powder metallurgy, ceramic consolidation |

| Advanced Manufacturing | Semiconductor fabrication, solar cell production |

| Material Synthesis | Development of optical, magnetic, and new energy materials |

Ready to elevate your lab's capabilities with tailored high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced furnaces like Atmosphere Tube, Muffle, Rotary, Vacuum, and CVD/PECVD Systems. Our deep customization ensures precise fit for your unique experimental needs in materials science, manufacturing, and research. Contact us today to discuss how we can enhance your processes with reliable, controlled heating environments!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity