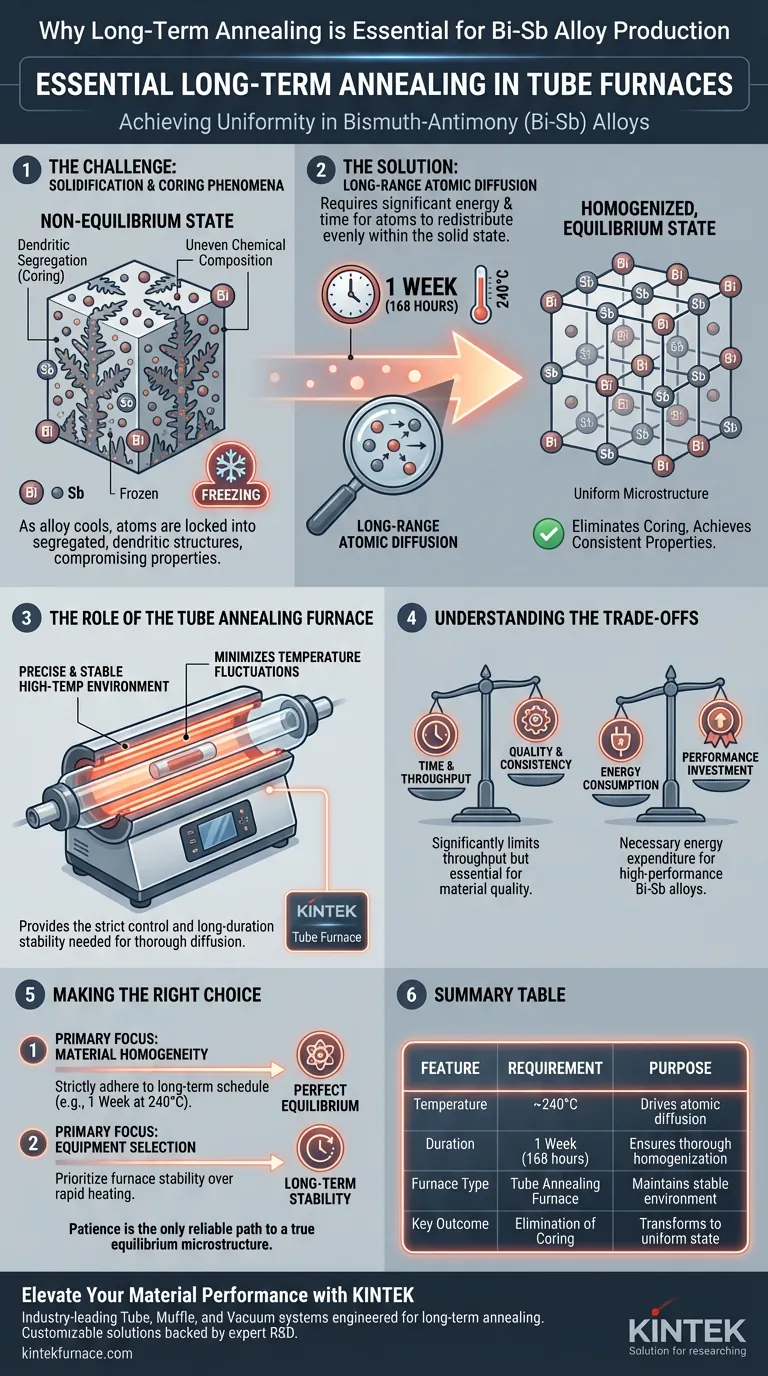

Long-term annealing acts as a critical stabilization phase for bismuth-antimony (Bi-Sb) alloys, correcting structural inconsistencies inherent to the solidification process. By maintaining a precise, elevated temperature over an extended period—often as long as one week—the process drives long-range atomic diffusion to eliminate segregation and achieve a uniform, equilibrium state.

Core Takeaway Solidification naturally results in "coring," where elements distribute unevenly across the alloy's microstructure. Long-term annealing in a stable tube furnace provides the sustained energy required to diffuse these atoms, transforming a segregated dendritic structure into a homogenized, high-performance material.

The Challenge of Solidification: Coring Phenomena

Understanding Dendritic Segregation

When Bi-Sb alloys solidify from a melt, they do not form a perfectly uniform structure immediately.

Instead, they suffer from coring phenomena, also known as dendritic segregation. This results in variations in chemical composition across the microstructure.

The Distance from Equilibrium

As the alloy cools, the resulting solid is effectively "frozen" in a non-equilibrium state.

Without intervention, this segregated structure compromises the consistency of the material's physical and electronic properties.

The Solution: Long-Range Atomic Diffusion

The Mechanism of Homogenization

To fix the segregation caused by coring, the atoms within the solid state must physically move to redistribute themselves evenly.

This process is known as long-range atomic diffusion. It requires significant energy and time to occur effectively within a solid material.

The Necessity of Extended Time

Diffusion in the solid state is a slow process compared to mixing in a liquid.

The primary reference notes that maintaining a temperature of 240 degrees Celsius for one week is a typical requirement. This duration ensures the diffusion process is thorough enough to reduce or eliminate the coring completely.

The Role of the Tube Annealing Furnace

Precision and Stability

The specific use of a tube annealing furnace is not arbitrary; it is chosen for its ability to maintain a strictly controlled environment.

This equipment provides the precise and stable high-temperature environment required for such a long duration.

Ensuring Consistent Results

Fluctuations in temperature over a week-long process could interrupt diffusion or introduce new inconsistencies.

The tube furnace minimizes these variables, ensuring the final microstructure reaches the desired equilibrium state.

Understanding the Trade-offs

Time vs. Throughput

The most significant trade-off in this process is the production bottleneck.

Dedicating a furnace to a single batch for an entire week significantly limits manufacturing throughput.

Energy Consumption

Maintaing 240 degrees Celsius for 168 hours (one week) represents a distinct energy cost.

However, skipping or shortening this step results in an inferior, segregated product, making the energy expenditure a necessary investment for quality.

Making the Right Choice for Your Goal

To optimize your Bi-Sb alloy production, align your process parameters with your quality requirements:

- If your primary focus is material homogeneity: Strictly adhere to the long-term annealing schedule (e.g., one week at 240°C) to guarantee the elimination of coring phenomena.

- If your primary focus is equipment selection: Ensure your furnace specifications prioritize long-term thermal stability over rapid heating rates, as consistency over time is the critical factor.

Patience in the annealing phase is the only reliable path to a true equilibrium microstructure in Bi-Sb alloys.

Summary Table:

| Feature | Requirement for Bi-Sb Alloys | Purpose |

|---|---|---|

| Temperature | ~240°C | Drives long-range atomic diffusion |

| Duration | 1 Week (168 hours) | Ensures thorough homogenization of structure |

| Furnace Type | Tube Annealing Furnace | Maintains precise, stable environment |

| Key Outcome | Elimination of Coring | Transforms non-equilibrium states to uniformity |

Elevate Your Material Performance with KINTEK

Precision in bismuth-antimony alloy production requires more than just heat; it requires absolute thermal stability over extended durations. KINTEK provides industry-leading Tube, Muffle, and Vacuum systems specifically engineered to handle the rigorous demands of long-term annealing processes.

Backed by expert R&D and manufacturing, our high-temp furnaces are fully customizable to meet your unique lab or production needs, ensuring your Bi-Sb alloys achieve a perfect equilibrium state every time.

Ready to optimize your heat treatment workflow? Contact us today to discuss your project requirements!

Visual Guide

References

- Dragan Manasijević, Ivana Marković. Thermal conductivity and microstructure of Bi-Sb alloys. DOI: 10.2298/hemind230829002m

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does the environmental control within a high-temperature tube furnace affect Ag-N-C catalyst pyrolysis?

- What common processes are enabled by tube furnaces? Unlock Precise Thermal Processing for Your Lab

- What is the primary role of a tubular furnace in industrial production? Achieve Precise Thermal Processing for Superior Materials

- What is an atmosphere tube furnace? Unlock Precise High-Temperature Processing

- What role do high-temperature tube or muffle furnaces play in biomass-derived carbon? Enhance Catalyst Performance

- What is the function of a stainless steel tubular horizontal reactor? Optimize Plastic Waste Catalytic Pyrolysis

- How does the sealing mechanism in Quartz Tube Furnaces differ from traditional systems? Discover Advanced Sealing for Reliable Results

- What are the advantages of a dual-zone tube furnace for APCVD of SnSe2? Master Phase Purity & Stoichiometry