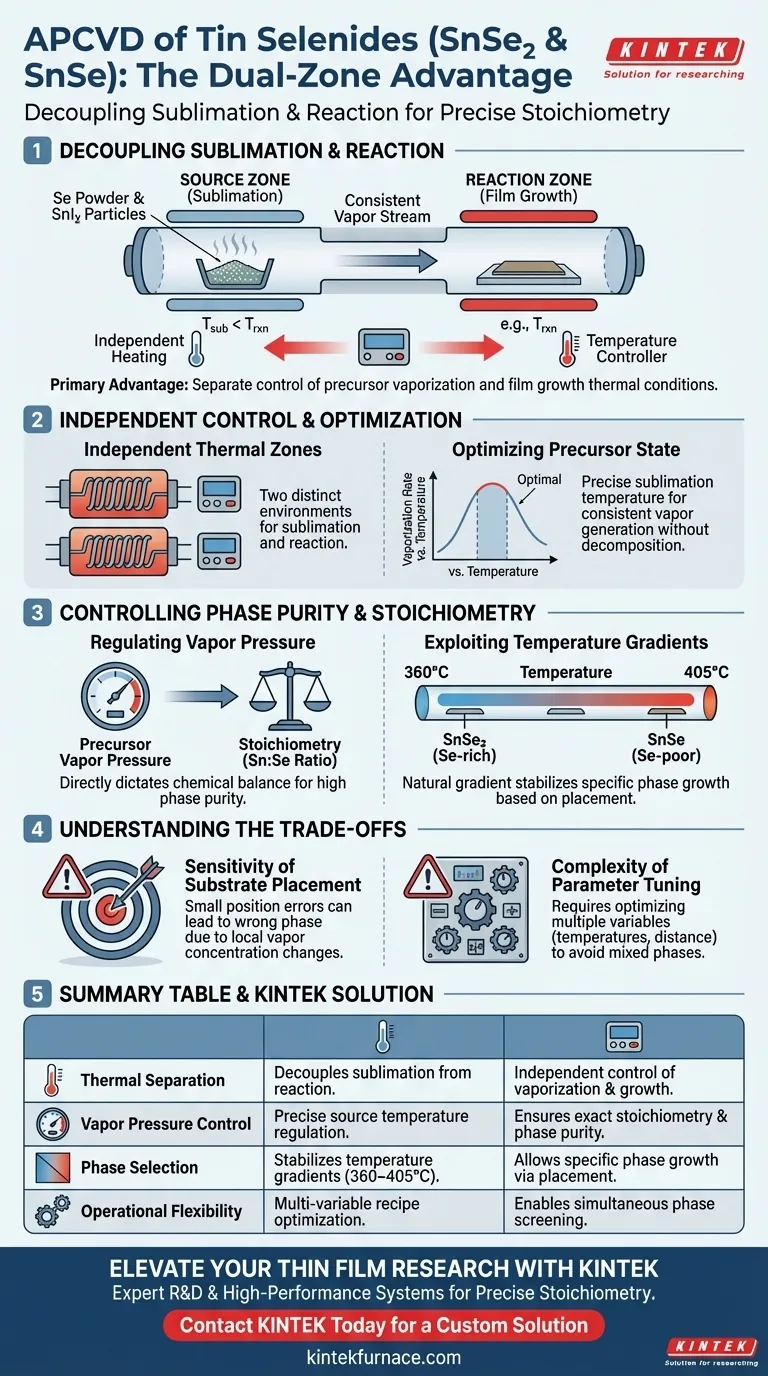

The primary advantage of a dual-zone tube furnace in Atmospheric Pressure Chemical Vapor Deposition (APCVD) is the ability to decouple the precursor sublimation temperature from the reaction zone temperature. This separation allows for precise control over the vaporization of solid precursors like Selenium (Se) powder and Tin Iodide (SnI2) without compromising the thermal conditions required for film growth.

By independently heating the source material and the substrate area, a dual-zone furnace enables exact regulation of precursor vapor pressure. This control is the deciding factor in achieving specific chemical stoichiometry and high phase purity for both Tin Diselenide (SnSe2) and Tin Selenide (SnSe).

Decoupling Sublimation and Reaction

Independent Thermal Zones

A dual-zone furnace provides two distinct heating environments that can be controlled individually.

One zone is dedicated to the sublimation of solid precursors, such as Selenium powder and Tin Iodide particles.

The second zone is dedicated to the reaction area, where the actual thin film growth occurs on the substrate.

Optimizing Precursor State

Solid precursors often require specific temperatures to vaporize at a rate that sustains the reaction without decomposing.

If the source temperature is tied to the reaction temperature (as in a single-zone furnace), you may vaporize the material too quickly or too slowly.

Dual-zone control allows you to set the sublimation temperature exactly where it needs to be to generate a consistent stream of vapor.

Controlling Phase Purity and Stoichiometry

Regulating Vapor Pressure

The quality of SnSe2 and SnSe films is heavily dependent on the ratio of reactants in the vapor phase.

By controlling the source zone temperature, you directly regulate the precursor vapor pressure.

This precise regulation dictates the chemical stoichiometry, ensuring the correct atomic balance between Tin and Selenium enters the reaction zone.

Exploiting Temperature Gradients

The reaction zone creates a natural temperature gradient, typically ranging from 360 to 405 degrees Celsius.

This gradient is essential because the thermodynamic stability of SnSe2 (Selenium-rich) and SnSe (Selenium-poor) differs by temperature.

The dual-zone setup maintains this gradient stably, allowing specific phases to grow based on the substrate's location within the tube.

Understanding the Trade-offs

Sensitivity of Substrate Placement

While the temperature gradient allows for phase selection, it introduces high sensitivity to placement.

Because the local concentration ratio of precursor vapors changes along the tube, a small error in substrate positioning can result in the wrong phase.

Complexity of Parameter Tuning

Dual-zone systems introduce more variables into the growth recipe.

You must optimize not only the growth temperature but also the source temperature and the distance between them.

Failing to balance the source vapor pressure with the reaction temperature can lead to mixed-phase films or incomplete growth.

Making the Right Choice for Your Goal

To maximize the effectiveness of a dual-zone APCVD setup, align your parameters with your specific material objectives:

- If your primary focus is Phase Purity (SnSe2 vs. SnSe): Calibrate the source zone to strictly control vapor pressure, as this dictates the stoichiometric availability of Selenium.

- If your primary focus is Phase Screening: Place multiple substrates along the natural temperature gradient (360–405°C) to grow both Selenium-rich and Selenium-poor phases in a single cycle.

Precise thermal separation between the source and the substrate is the key to mastering the stoichiometry of tin selenide thin films.

Summary Table:

| Feature | Dual-Zone Benefit | Impact on SnSe2/SnSe Growth |

|---|---|---|

| Thermal Separation | Decouples sublimation from reaction zone | Independent control of precursor vaporization and film growth. |

| Vapor Pressure Control | Precise regulation of source zone temperature | Ensures exact chemical stoichiometry and phase purity. |

| Phase Selection | Stabilizes temperature gradients (360–405°C) | Allows growth of specific phases (SnSe2 vs SnSe) via placement. |

| Operational Flexibility | Multi-variable recipe optimization | Enables simultaneous phase screening and material discovery. |

Elevate Your Thin Film Research with KINTEK

Precise stoichiometry in APCVD requires specialized thermal control. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of material science.

Whether you are growing Selenium-rich SnSe2 or Selenium-poor SnSe, our dual-zone furnaces provide the thermal stability and customization necessary for high-phase purity. Don't settle for inconsistent results—let our experts help you configure the perfect system for your unique lab needs.

Contact KINTEK Today for a Custom Solution

Visual Guide

References

- Manab Mandal, K. Sethupathi. In Situ Simultaneous Growth of Layered SnSe<sub>2</sub> and SnSe: a Linear Precursor Approach. DOI: 10.1002/admi.202500239

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What advantages does a dual-zone tube furnace offer for carbon spheres? Enhanced Control & Superior Morphology

- Why is a dual-zone tube furnace necessary for MnO2/CF phosphorization? Master CVD Synthesis with Precision Control

- How does a dual-temperature zone tube furnace control crystal quality? Master PVT for Organic Single Crystals

- How does a programmable tube furnace facilitate Al/SiC material transformation? Precision Heat for Ceramic Coatings

- What role does a tube furnace play within a Vapor Transport Deposition (VTD) system? Essential Role in Thin Film Growth