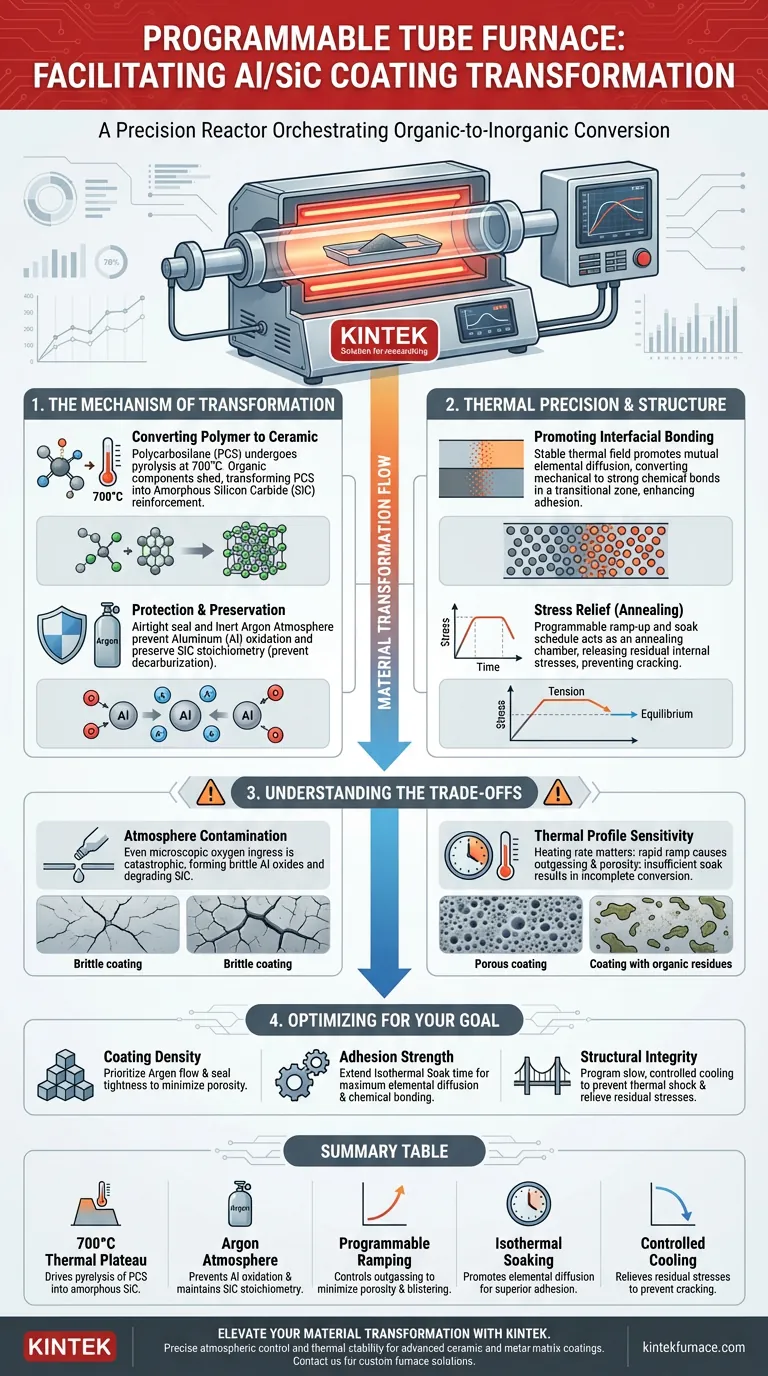

A programmable tube furnace serves as a precision reactor that orchestrates the chemical conversion of organic polymers into inorganic ceramics. Specifically, for Al/SiC coatings, it maintains a strictly controlled 700 °C environment under an inert argon atmosphere. This setup drives the transformation of Polycarbosilane (PCS) into amorphous Silicon Carbide (SiC) while simultaneously preventing the oxidation of the aluminum matrix, resulting in a high-density composite barrier.

Core Takeaway The programmable tube furnace is not merely a heating element; it is an atmospheric control system that decouples high temperature from oxidation. Its primary function in this application is to enable the pyrolysis of precursors into ceramics without compromising the chemical integrity of the reactive metal substrate.

The Mechanism of Material Transformation

To understand the furnace's role, one must look beyond simple heating and examine the chemical engineering occurring inside the tube.

Converting Polymer to Ceramic

The core transformation relies on converting Polycarbosilane (PCS), an organic polymer, into an inorganic material.

The furnace holds the material at a steady 700 °C. At this specific thermal plateau, PCS undergoes pyrolysis, shedding its organic components. This process effectively turns the polymer into amorphous Silicon Carbide (SiC) ceramic, which acts as the reinforcement in the coating.

Protection via Inert Atmosphere

Creating SiC is only half the battle; protecting the aluminum (Al) is the other.

Aluminum is highly reactive to oxygen, especially at high temperatures. The tube furnace utilizes an airtight seal to maintain a pure argon atmosphere. This inert environment is non-negotiable, as it prevents oxygen ingress that would otherwise rapidly oxidize the aluminum powder.

Preserving Carbon Content

The inert atmosphere serves a dual purpose: it protects the aluminum and preserves the SiC.

If oxygen were present, the Silicon Carbide could suffer from decarburization (loss of carbon). By excluding oxygen, the furnace ensures the SiC retains its correct stoichiometry. This results in a metal-ceramic composite that is both chemically stable and structurally dense.

The Role of Thermal Precision and Diffusion

While the primary transformation is chemical, the physical application of heat plays a critical structural role.

Promoting Interfacial Bonding

A programmable furnace ensures a stable thermal field, which is essential for diffusion.

Drawing on principles seen in vacuum heat treatments, the high-temperature environment promotes the mutual diffusion of elements. This helps convert mechanical bonds between particles into stronger chemical bonds. In the context of Al/SiC, this leads to a "transitional bonding zone" that significantly enhances adhesion and reduces the risk of the coating spalling (flaking off).

Stress Relief

Coatings applied via spraying or dipping often contain residual internal stresses.

By adhering to a programmable ramp-up and soak schedule, the furnace acts as an annealing chamber. This thermal cycle allows the internal phases of the coating to reach equilibrium, releasing residual stresses that could otherwise lead to premature cracking or failure.

Understanding the Trade-offs

While the tube furnace is a powerful tool, it requires rigorous process control to avoid defects.

The Risk of Atmosphere Contamination

The system's reliability is entirely dependent on the integrity of the airtight seal. Even a microscopic leak in the tube or flange can introduce oxygen.

In an Al/SiC process, oxygen ingress is catastrophic. It leads to the formation of brittle aluminum oxides rather than the desired metal matrix, and it degrades the ceramic reinforcement.

Thermal Profile Sensitivity

The "programmable" aspect of the furnace is critical because the heating rate matters as much as the final temperature.

Ramping up too quickly can cause rapid outgassing of the organic PCS solvents, leading to porosity or blistering in the coating. Conversely, insufficient soak times at 700 °C may result in incomplete conversion of the polymer, leaving behind weak organic residues rather than strong inorganic ceramics.

Making the Right Choice for Your Goal

When configuring your furnace protocols for Al/SiC coatings, align your settings with your specific engineering objectives.

- If your primary focus is Coating Density: Prioritize the integrity of the argon flow and seal tightness to absolutely minimize porosity caused by oxidation or decarburization.

- If your primary focus is Adhesion Strength: Extend the isothermal soak time at peak temperature to maximize elemental diffusion and the formation of a chemical bonding zone.

- If your primary focus is Structural Integrity: Program a slow, controlled cooling ramp to prevent thermal shock and ensure residual stresses are fully relieved before the part reaches room temperature.

Ultimately, the programmable tube furnace transforms a mixture of powders and polymers into a unified high-performance composite by strictly governing the chemistry of the heating environment.

Summary Table:

| Process Component | Role in Al/SiC Transformation |

|---|---|

| 700 °C Thermal Plateau | Drives pyrolysis of Polycarbosilane (PCS) into amorphous Silicon Carbide (SiC) |

| Argon Atmosphere | Prevents aluminum oxidation and maintains correct SiC stoichiometry |

| Programmable Ramping | Controls outgassing to minimize porosity and prevents coating blistering |

| Isothermal Soaking | Promotes elemental diffusion for superior chemical bonding and adhesion |

| Controlled Cooling | Relieves residual internal stresses to prevent cracking and spalling |

Elevate Your Material Transformation with KINTEK

Precise atmospheric control and thermal stability are the difference between a brittle layer and a high-density composite. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems designed for the rigorous demands of advanced ceramic and metal-matrix coating research.

Our expert R&D and manufacturing teams offer fully customizable high-temp furnace solutions tailored to your specific heating profiles and gas requirements. Contact us today to discuss your unique project needs and see how KINTEK can optimize your lab's performance.

Visual Guide

References

- María Fernanda Valerio-Rodríguez, Eddie López‐Honorato. Composite coatings from polycarbosilane derived SiC and Al/SiC cermet active fillers as protective barriers against steel corrosion. DOI: 10.1007/s12633-024-03115-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the common features of the heating chamber in a horizontal tube furnace? Achieve Precise Thermal Control for Your Lab

- What role does a vacuum-controlled tube furnace play in Ti2AlN treatment? Master the Hexagonal MAX Phase Transition

- What is the necessity of using high-temperature tube furnaces for annealing? Master Quantum Emitter Fabrication

- What are some examples of tube furnace models and their ideal applications? Find Your Perfect Match for Precise Thermal Processing

- What are the common applications of tube furnaces? Unlock Precision in Material Processing

- What is the necessity of the 500 °C hydrogen environment provided by a tube reduction furnace? Master Catalyst Activation

- What is the process for using a vacuum tube experimental furnace? Master Precise Control for Your Lab

- How does a two-stage heating process in a laboratory tube furnace contribute to the structural formation of SiCN(Ni)/BN?