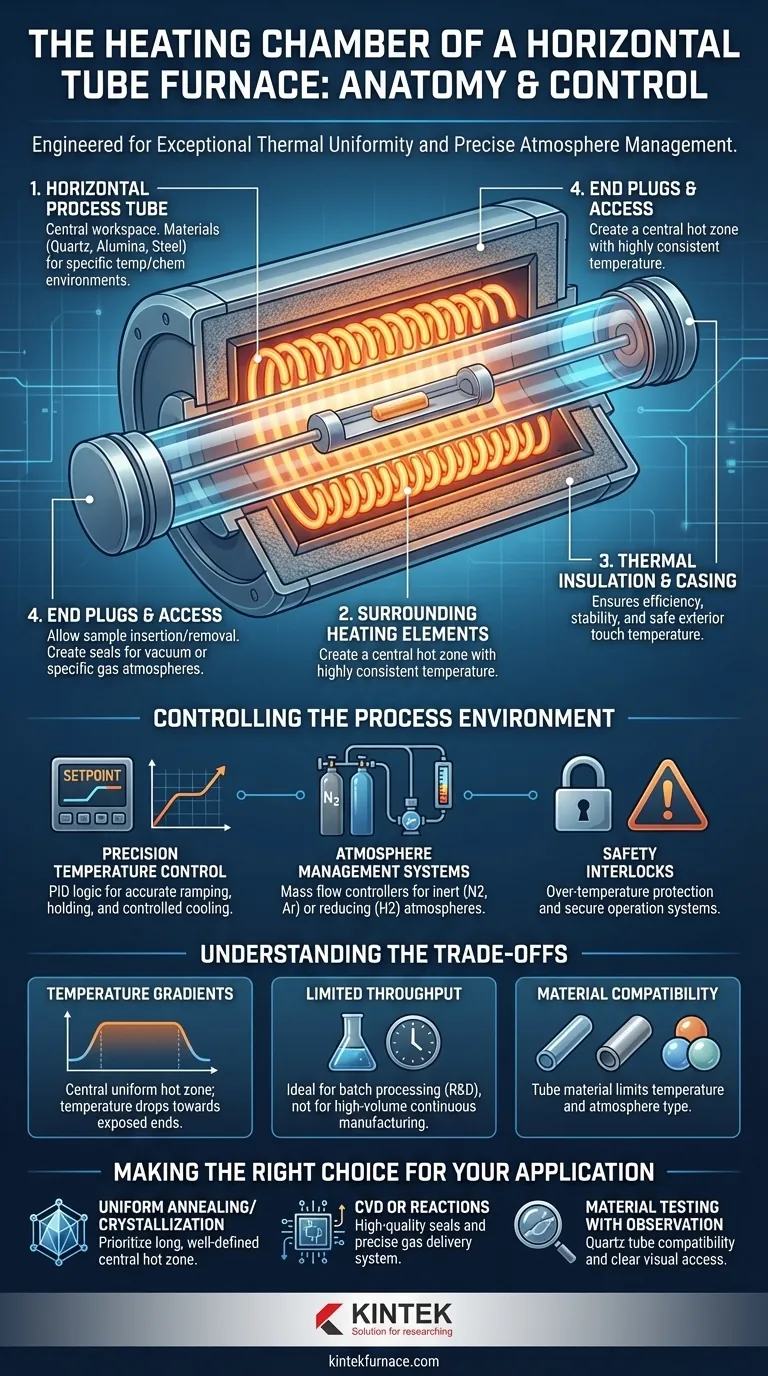

At its core, the heating chamber of a horizontal tube furnace is an engineered system designed for exceptional thermal uniformity and control. Its defining features include a horizontally oriented process tube, surrounded by heating elements that create a consistent hot zone, and sealed end plugs that allow for both easy access and precise atmosphere management.

A horizontal tube furnace's heating chamber is more than just a hot enclosure. Its features are engineered with a singular purpose: to create a precisely controlled and exceptionally uniform thermal environment along a linear axis, making it ideal for processes that demand consistent treatment of materials.

The Anatomy of the Heating Chamber

To understand the furnace's capabilities, we must first break down the components of its heating chamber. Each part serves a specific function in achieving a controlled thermal process.

The Horizontal Process Tube

This is the central workspace of the furnace where the sample is placed. Its horizontal orientation is ideal for processes requiring a consistent temperature profile over a specific length.

Tubes are made from different materials to suit various temperatures and chemical environments. Common materials include quartz glass for observation and purity, alumina for very high temperatures, and heat-resistant steel for durability.

Surrounding Heating Elements

Heating elements are positioned around the process tube to ensure efficient and uniform heat transfer. This design creates a central hot zone with a highly consistent temperature.

The quality of these elements and their placement are critical for minimizing temperature gradients along the length of the sample being processed.

Thermal Insulation and Casing

High-quality thermal insulation surrounds the heating elements. This component is crucial for achieving high temperatures efficiently, maintaining temperature stability, and ensuring the exterior of the furnace remains safe to the touch.

The compact, space-saving design of many modern furnaces is a direct result of advances in these insulating materials.

End Plugs and Access

The process tube is accessible via end plugs or flanges. These are designed for easy insertion and removal of samples.

Crucially, these plugs also create a seal. This allows the chamber to hold a vacuum or be filled with a specific gas, enabling processes in inert or reducing atmospheres.

Controlling the Process Environment

The physical components work in concert with control systems to create a highly specific and repeatable environment. This level of control is what makes the tube furnace a vital scientific instrument.

Precision Temperature Control

Modern furnaces use sophisticated controllers, often with PID (Proportional-Integral-Derivative) logic, to precisely regulate power to the heating elements. This allows for accurate ramping to a setpoint, holding a stable temperature, and controlled cooling.

Uniform Heat Distribution

The primary advantage of the horizontal design is its ability to deliver a uniform thermal profile along the tube's central axis. This is essential for applications like annealing, where every part of the sample must experience the same thermal history to achieve consistent material properties.

Atmosphere Management Systems

Many furnaces can be equipped with gas delivery systems. Using mass flow controllers, these systems allow for the precise introduction of gases like nitrogen or argon to create an inert atmosphere, or hydrogen for a reducing atmosphere. This prevents unwanted oxidation or facilitates specific chemical reactions.

Safety Interlocks

Essential safety features are integrated into the design. These include over-temperature protection, which automatically shuts down the furnace if it exceeds a safe limit, and interlocks that may prevent operation if doors or seals are not properly secured.

Understanding the Trade-offs

While powerful, the design of a horizontal tube furnace presents inherent trade-offs that are important to understand for proper application.

Temperature Gradients at the Ends

The "central hot zone" is by definition in the middle. The temperature will naturally drop off toward the ends of the tube that are exposed to ambient air. Accurate processing requires placing the sample entirely within the calibrated uniform zone.

Limited Sample Throughput

Horizontal tube furnaces are typically used for batch processing. This is ideal for research, development, and small-scale production, but it may not be suitable for high-volume, continuous manufacturing processes.

Material and Atmosphere Compatibility

The choice of process tube material dictates the furnace's ultimate limits. A quartz tube offers excellent visibility but has a lower maximum temperature than an alumina tube. Likewise, some reactive gases may degrade certain tube materials over time.

Making the Right Choice for Your Application

Selecting and using a horizontal tube furnace effectively means matching its features to your specific process goal.

- If your primary focus is uniform annealing or crystallization: Prioritize a furnace with a long, well-defined central hot zone to ensure consistent material properties.

- If your primary focus is chemical vapor deposition (CVD) or reactions: You need a system with high-quality seals and an integrated gas delivery system for precise atmosphere control.

- If your primary focus is material testing with in-situ observation: Select a furnace compatible with a quartz tube and ensure the setup provides clear visual access.

Ultimately, understanding these core features empowers you to select and operate a furnace that precisely matches your material processing objectives.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Horizontal Process Tube | Central workspace for samples, made from materials like quartz or alumina | Enables consistent temperature profile and material compatibility |

| Heating Elements | Surround the tube for efficient heat transfer | Creates a uniform hot zone with minimal temperature gradients |

| Thermal Insulation | High-quality materials for efficiency and safety | Maintains temperature stability and safe exterior |

| End Plugs and Seals | Allow sample access and atmosphere control | Supports vacuum or specific gas environments for precise processes |

| Control Systems | PID controllers for temperature regulation | Ensures accurate ramping, holding, and cooling |

| Atmosphere Management | Gas delivery with mass flow controllers | Facilitates inert or reducing atmospheres to prevent oxidation |

| Safety Interlocks | Over-temperature protection and door interlocks | Enhances operational safety and prevents accidents |

Ready to enhance your laboratory's capabilities with a custom high-temperature furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior thermal uniformity, precise atmosphere control, and reliable performance for diverse applications. Don't settle for less—contact us today to discuss how we can optimize your material processing and drive your research forward!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment