In essence, a tube furnace is a high-temperature oven used for a vast range of thermal processes across research and industry. Its core applications involve material synthesis, heat treatment, and specialized testing where precise control over both temperature and atmosphere is critical. Common uses include annealing metals, sintering ceramic powders, growing thin films via chemical vapor deposition (CVD), and calibrating temperature sensors.

The primary reason to choose a tube furnace is not just for high heat, but for unmatched control over the processing environment. Its sealed tube design is what enables the precise management of gas atmospheres or vacuums, which is a non-negotiable requirement for advanced material processing.

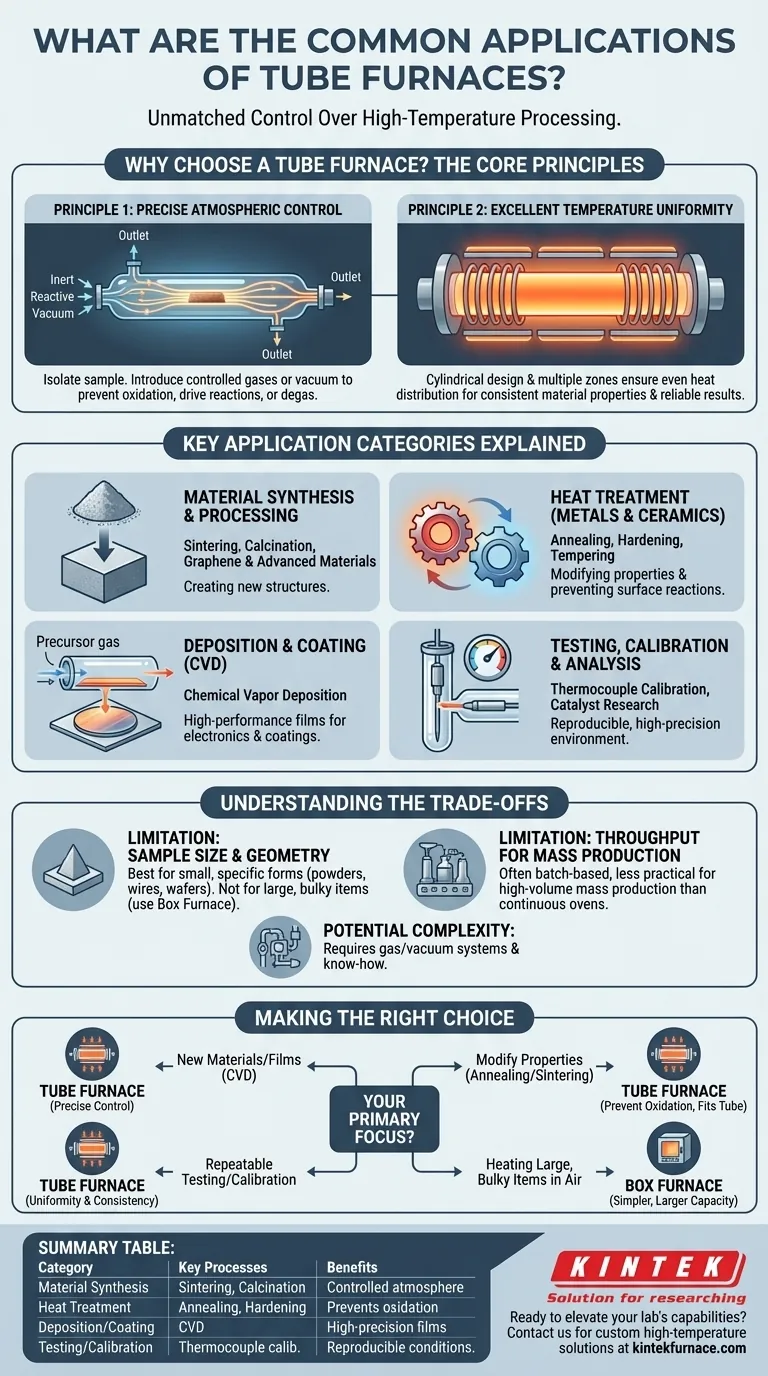

Why Choose a Tube Furnace? The Core Principles

While the list of applications is long, they all stem from two fundamental capabilities that set tube furnaces apart from other heating equipment like box furnaces.

Principle 1: Precise Atmospheric Control

The defining feature of a tube furnace is its ability to isolate a sample from the ambient air. The process tube, typically made of quartz, alumina, or a metal alloy, can be sealed at both ends.

This allows you to introduce a tightly controlled environment. You can flow inert gases (like argon or nitrogen) to prevent oxidation, use reactive gases (like hydrogen) to drive chemical reactions, or create a vacuum to degas materials or perform processes in a pure environment.

Principle 2: Excellent Temperature Uniformity

The cylindrical geometry of the heating chamber naturally promotes an even distribution of heat. Many models also feature multiple, independently controlled heating zones along the length of the tube.

This design creates a highly stable and uniform hot zone, ensuring that the entire sample experiences the exact same thermal profile. This uniformity is crucial for achieving consistent material properties, reliable test results, and high-yield production.

Key Application Categories Explained

The combination of atmospheric control and temperature uniformity makes the tube furnace an indispensable tool in several key areas.

Material Synthesis and Processing

This is one of the broadest and most common uses. It involves creating new materials or fundamentally changing their structure.

Applications include sintering (heating powders below their melting point to form a solid mass), calcination (heating to remove impurities or volatile substances), and the synthesis of advanced materials like graphene, polymers, and battery components.

Heat Treatment of Metals and Ceramics

Tube furnaces are workhorses in metallurgy and ceramics for modifying material properties.

Key processes include annealing (heating and slow cooling to soften a material and relieve internal stresses), hardening (heating and rapid cooling to increase strength), and tempering (heating to a lower temperature after hardening to increase toughness). The controlled atmosphere prevents unwanted surface reactions like scaling.

Deposition and Coating Processes

This category is critical for the semiconductor and advanced coatings industries. The most prominent application is Chemical Vapor Deposition (CVD).

In CVD, precursor gases are introduced into the hot tube furnace, where they react and deposit a thin, solid film onto a substrate. This is how many high-performance coatings and electronic materials are made.

Testing, Calibration, and Analysis

The highly repeatable environment of a tube furnace makes it ideal for scientific and quality control applications.

It is the standard for thermocouple calibration, where sensors are checked against known temperature points. It is also used for catalyst research, fuel cell testing, and aerospace materials testing, where samples must be evaluated under specific, reproducible atmospheric and thermal conditions.

Understanding the Trade-offs

While incredibly versatile, a tube furnace is not the right tool for every job. Understanding its limitations is key to making a wise investment.

Limitation: Sample Size and Geometry

By design, tube furnaces are best suited for smaller samples or materials with a specific form factor, such as powders, small parts, wafers, wires, or strips that can easily slide into the tube.

They are not practical for heating large, bulky, or irregularly shaped objects. For those tasks, a box furnace or chamber oven is a more appropriate choice.

Limitation: Throughput for Mass Production

While some continuous-feed systems exist, many research and pilot-scale tube furnaces operate in batches. This can be a bottleneck for high-volume mass production compared to dedicated industrial conveyor ovens.

Potential Complexity

A simple, air-only tube furnace is straightforward. However, systems designed for high vacuum or reactive gas handling require more complex plumbing, safety interlocks, and control systems, which increases both cost and operational know-how.

Making the Right Choice for Your Goal

To decide if a tube furnace is the correct equipment, match your primary objective to its core strengths.

- If your primary focus is creating new materials or thin films (CVD, synthesis): The tube furnace is likely essential due to its precise atmospheric control.

- If your primary focus is modifying the properties of metals or ceramics (annealing, sintering): The tube furnace is an excellent choice, especially if preventing oxidation is important and your parts fit within the tube.

- If your primary focus is repeatable, high-precision testing or calibration: The superior temperature uniformity and controlled environment make the tube furnace the ideal instrument.

- If your primary focus is simply heating large, bulky items in air: You should consider a less complex and more size-appropriate box furnace instead.

Understanding these core capabilities empowers you to see the tube furnace not as a simple oven, but as a precise instrument for advanced thermal processing.

Summary Table:

| Application Category | Key Processes | Benefits |

|---|---|---|

| Material Synthesis | Sintering, calcination, graphene synthesis | Controlled atmosphere, uniform heating |

| Heat Treatment | Annealing, hardening, tempering | Prevents oxidation, consistent results |

| Deposition and Coating | Chemical Vapor Deposition (CVD) | High-precision thin film growth |

| Testing and Calibration | Thermocouple calibration, catalyst research | Reproducible conditions, accuracy |

Ready to elevate your lab's capabilities with a custom tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in research, materials science, or industrial processing, we can help you achieve precise thermal and atmospheric control for superior results. Contact us today to discuss how we can support your specific applications!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing