In practice, the ideal tube furnace model is dictated entirely by the thermal process you need to perform. For instance, a furnace with multiple, independently controlled heating zones is necessary for creating a precise temperature gradient for applications like chemical vapor deposition (CVD). Conversely, a simple, single-zone furnace is perfectly sufficient and more cost-effective for basic processes like uniform annealing or drying materials.

The core principle is not to find the "best" furnace, but to match the furnace's design—specifically its number of heating zones and physical orientation—to the specific requirements of your scientific or industrial process.

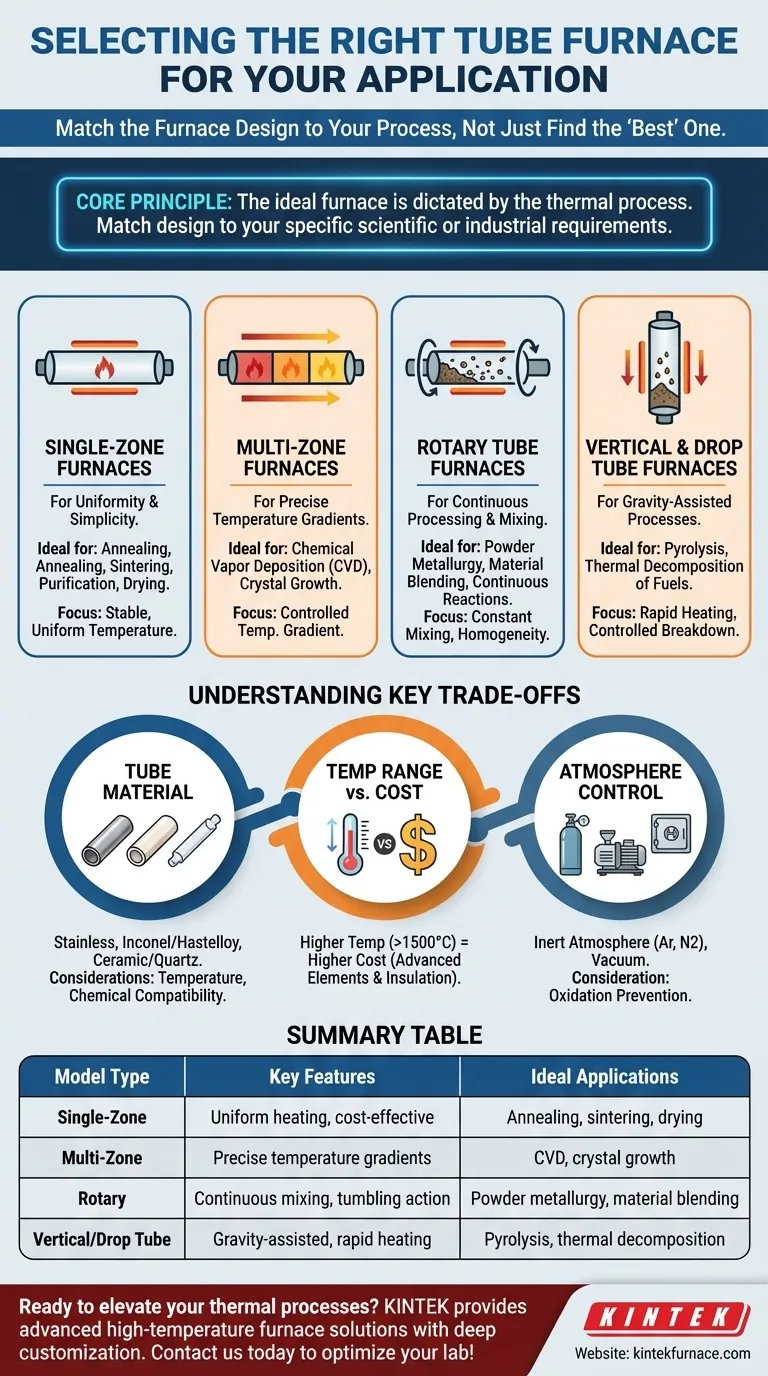

Matching Furnace Design to Your Process

The architecture of a tube furnace is a direct reflection of its intended function. Understanding these fundamental designs is the key to selecting the correct tool for your work.

Single-Zone Furnaces: For Uniformity and Simplicity

The most common type of tube furnace features a single heating zone. Its primary purpose is to create a stable, uniform temperature across the central portion of the process tube.

These models are workhorses for a wide range of general-purpose applications, including annealing, sintering, purification, and drying. If your goal is to heat a sample to one specific temperature and hold it there, a single-zone furnace is the most direct and efficient choice.

Multi-Zone Furnaces: For Precise Temperature Gradients

For more advanced processes, a furnace with two, three, or even eight or more independent heating zones is required. Each zone can be set to a different temperature, creating a controlled temperature gradient along the length of the tube.

This capability is critical for applications like chemical vapor deposition (CVD) and certain types of crystal growth, where reactants must be heated or vaporized at one temperature before flowing into a different temperature zone for deposition or reaction.

Rotary Tube Furnaces: For Continuous Processing and Mixing

A rotary tube furnace, also known as a rotary calciner, is designed to tumble the material as it is being heated. The entire tube assembly rotates, ensuring that every particle is continuously mixed and uniformly exposed to the heat.

This makes them indispensable for the continuous processing of powders, granular materials, and slurries. Key applications include powder metallurgy, material blending, and chemical reactions that require constant agitation for homogeneity.

Vertical & Drop Tube Furnaces: For Gravity-Assisted Processes

Orienting the furnace vertically allows gravity to assist in the process. In a "drop tube" configuration, material is dropped from the top and passes through the hot zone as it falls.

This design is ideal for studying rapid heating events, such as pyrolysis and thermal decomposition of fuels like coal or biomass. It enables researchers to analyze how materials break down at high temperatures in a controlled, oxygen-free environment.

Understanding the Key Trade-offs

Selecting a furnace model is only part of the decision. You must also consider the materials and operational constraints, as these factors have significant performance and cost implications.

The Importance of Tube Material

The process tube itself is a critical component. Its material must withstand your target temperature and be chemically compatible with your sample and any process gases.

- Stainless Steel: A good general-purpose choice for its oxidation resistance at moderate temperatures.

- Inconel or Hastelloy: High-performance nickel alloys required for extreme environments involving very high temperatures or corrosive atmospheres.

- Ceramic (Alumina) or Quartz: Used for ultra-high temperature applications or when extreme chemical inertness is required to prevent sample contamination.

Temperature Range vs. Cost

There is a direct correlation between a furnace's maximum operating temperature and its cost. Furnaces capable of reaching ultra-high temperatures (above 1500°C) require more expensive heating elements (e.g., molybdenum disilicide) and advanced insulation, significantly increasing their price.

Atmosphere Control

Many applications, such as annealing certain metals or performing pyrolysis, require an inert atmosphere to prevent oxidation. Ensure the furnace model you choose can be properly sealed and equipped with gas ports to allow for vacuum purging and the introduction of gases like argon or nitrogen.

Making the Right Choice for Your Application

To select the correct furnace, align its core design with the primary goal of your process.

- If your primary focus is uniform heating and annealing: A single-zone furnace provides the necessary temperature stability in the most cost-effective package.

- If your primary focus is complex synthesis like CVD: A multi-zone furnace is non-negotiable for creating the required temperature gradients.

- If your primary focus is processing powders or granules continuously: A rotary tube furnace is the only design that ensures constant mixing and uniform heating.

- If your primary focus is studying rapid thermal decomposition: A vertical or drop tube furnace offers the ideal configuration for controlled, gravity-assisted material testing.

Ultimately, a clear understanding of your process requirements will guide you to the correct furnace design.

Summary Table:

| Model Type | Key Features | Ideal Applications |

|---|---|---|

| Single-Zone | Uniform heating, cost-effective | Annealing, sintering, drying |

| Multi-Zone | Precise temperature gradients | Chemical vapor deposition (CVD), crystal growth |

| Rotary | Continuous mixing, tumbling action | Powder metallurgy, material blending |

| Vertical/Drop Tube | Gravity-assisted, rapid heating | Pyrolysis, thermal decomposition |

Ready to elevate your thermal processes with the perfect tube furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability