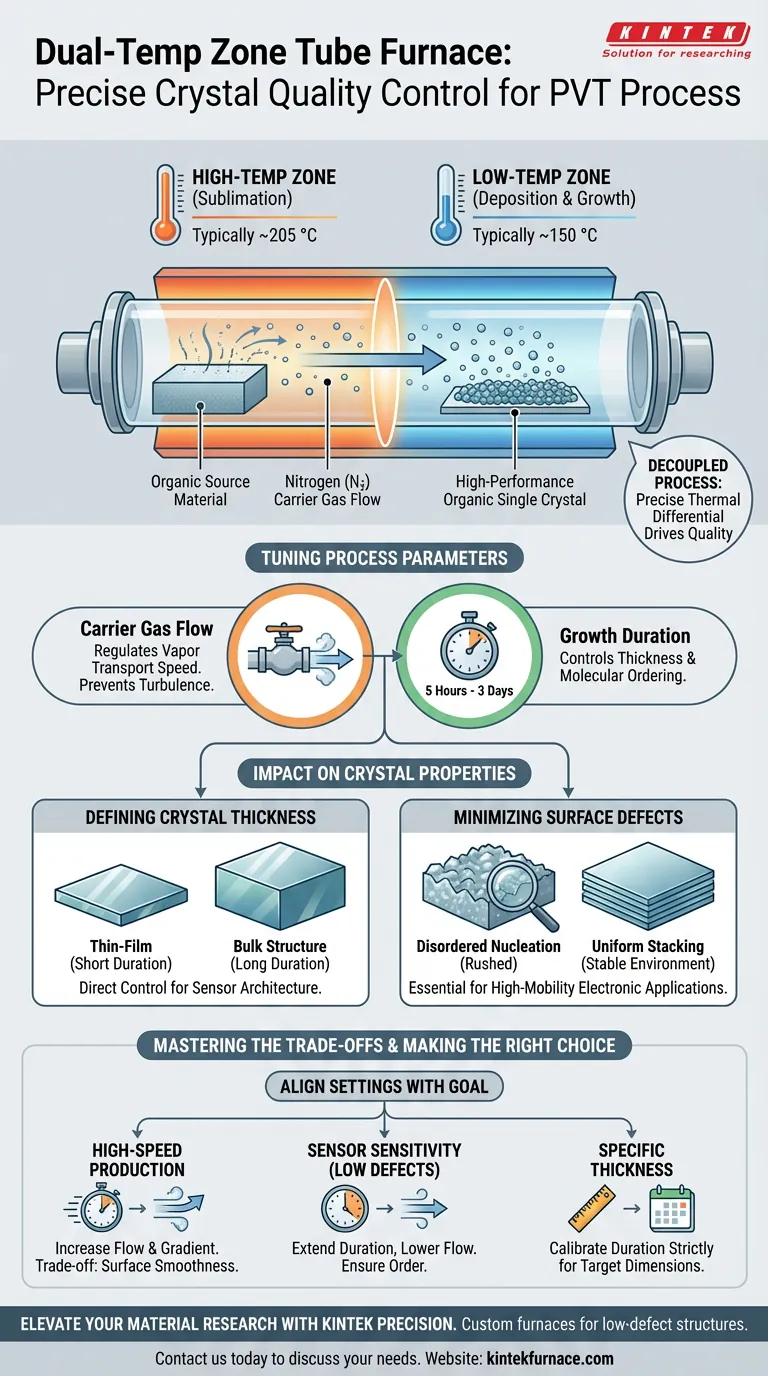

A dual-temperature zone tube furnace acts as the precise regulator of the crystallization environment. It controls crystal quality by establishing a stable temperature gradient that drives sublimation in a hot zone (typically 205 °C) and controlled deposition in a cooler zone (typically 150 °C). By managing this gradient alongside nitrogen carrier gas flow and growth duration, the system dictates the specific thickness and surface defect density of the final organic crystals.

Core Takeaway Achieving high-performance organic single crystals requires decoupling the source evaporation from the crystal growth. The dual-temperature zone furnace accomplishes this by maintaining a precise thermal differential, allowing you to tune the vapor transport rate to meet specific sensor requirements, ranging from ultra-thin films to thick, low-defect structures.

The Mechanism of Temperature Control

Establishing the Thermal Gradient

The fundamental mechanism of the furnace is the creation of two distinct thermal environments within a single sealed system.

In the high-temperature zone, the organic raw material is heated to its sublimation point, commonly around 205 °C. This phase change converts the solid source material into a vapor without reaching temperatures that would degrade the delicate organic compounds.

Controlling Nucleation and Growth

The vapor migrates toward the low-temperature zone, which is maintained at a cooler temperature, typically around 150 °C.

This lower temperature causes the vapor to become supersaturated and crystallize (nucleate) onto a substrate. By keeping this zone at a strictly controlled temperature, the furnace ensures that crystallization happens at a steady, manageable rate rather than a chaotic rush.

Tuning Process Parameters

Regulating Carrier Gas Flow

While temperature creates the potential for movement, the carrier gas (specifically nitrogen in this context) acts as the vehicle.

By regulating the flow rate of nitrogen, the furnace controls how quickly the sublimated vapor reaches the growth zone. Precise flow regulation prevents turbulence that could introduce structural irregularities into the crystal lattice.

Managing Growth Duration

The dual-zone setup allows for extreme flexibility in growth timelines, ranging from 5 hours to 3 days.

Short durations are sufficient for thinner structures, while multi-day sessions allow for the slow, methodical organization of molecules required for thicker, high-purity crystals.

Impact on Crystal Properties

Defining Crystal Thickness

The combination of gas flow, temperature differential, and time gives operators direct control over the physical dimensions of the product.

You can tweak these variables to produce crystals with specific thicknesses tailored to different sensor architectures, ensuring the material fits the device rather than forcing the device to fit the material.

Minimizing Surface Defects

High-performance sensors require crystals with minimal surface step defect density.

The dual-zone furnace minimizes these defects by maintaining a stable environment. When the temperature gradient is consistent, the molecular stacking is uniform, resulting in a smoother surface topography essential for high-mobility electronic applications.

Understanding the Trade-offs

While a dual-temperature zone furnace offers high precision, it requires balancing competing variables.

Speed vs. Quality Increasing the temperature gradient or gas flow can speed up the transport of material, effectively shortening the production cycle. However, rushing the process often leads to disordered nucleation and higher defect densities, compromising the electronic performance of the crystal.

Thermal Sensitivity Organic materials are far more sensitive to heat than inorganic metals or ceramics. If the high-temperature zone exceeds the specific sublimation point of the organic compound even slightly, the material may decompose rather than sublime, ruining the batch.

Making the Right Choice for Your Goal

To maximize the utility of a dual-temperature zone furnace, you must align your settings with your specific end-goal.

- If your primary focus is High-Speed Production: Increase the carrier gas flow rate and widen the temperature gradient slightly to accelerate vapor transport, accepting a potential trade-off in surface smoothness.

- If your primary focus is Sensor Sensitivity (Low Defects): Extend the growth duration to the full 3-day range and lower the gas flow rate to ensure the slowest, most ordered molecular stacking possible.

- If your primary focus is Specific Thickness: Calibrate the growth duration strictly; use shorter times for thin-film applications and longer durations for bulk crystal requirements.

By mastering the interplay between the thermal gradient and carrier gas flow, you transform the furnace from a simple heater into a precision instrument for material engineering.

Summary Table:

| Parameter | High-Temp Zone (Sublimation) | Low-Temp Zone (Deposition) | Impact on Quality |

|---|---|---|---|

| Temperature | Typically 205 °C | Typically 150 °C | Defines supersaturation and nucleation rate |

| Carrier Gas | Nitrogen Flow Control | Nitrogen Flow Control | Prevents turbulence and structural irregularities |

| Duration | 5 Hours to 3 Days | 5 Hours to 3 Days | Controls crystal thickness and molecular stacking |

| Focus | Source Evaporation | Controlled Crystallization | Minimizes surface step defect density |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect thermal gradient is critical for high-performance organic single crystals. KINTEK provides state-of-the-art Tube, Muffle, Rotary, and Vacuum CVD systems, all designed with precision R&D and expert manufacturing. Our dual-temperature zone furnaces are fully customizable to meet your specific sublimation and deposition requirements, ensuring low-defect structures and optimized sensor performance.

Ready to refine your crystallization process? Contact us today to discuss your custom furnace needs with our technical team.

Visual Guide

References

- Bin Lü, Tao He. High Sensitivity and Ultra‐Broad‐Range NH<sub>3</sub> Sensor Arrays by Precise Control of Step Defects on The Surface of Cl<sub>2</sub>‐Ndi Single Crystals. DOI: 10.1002/advs.202308036

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How do controlled tube furnace systems achieve atmosphere regulation? Study Zirconia Phase Transformation Laws

- What advanced materials research applications involve tube furnaces? Unlock Precision for Next-Gen Materials

- What role does a dual-zone tube furnace play in TaAs2 single crystal growth? Master Precision Temperature Gradients

- What are the drawbacks of corundum tube furnaces? Manage Costs, Visibility, and Thermal Risks

- Why are horizontal tube furnaces ideal for small scale materials tests? Unlock Precision and Efficiency in Your Lab

- What are the primary applications of tubular furnaces? Precision Heat Treatment for Research and Industry

- What is the significance of the heating zone in a vertical tube furnace? Unlock Precision for Material Processing

- How do tube furnaces compare to box furnaces? Choose the Right Furnace for Your Lab