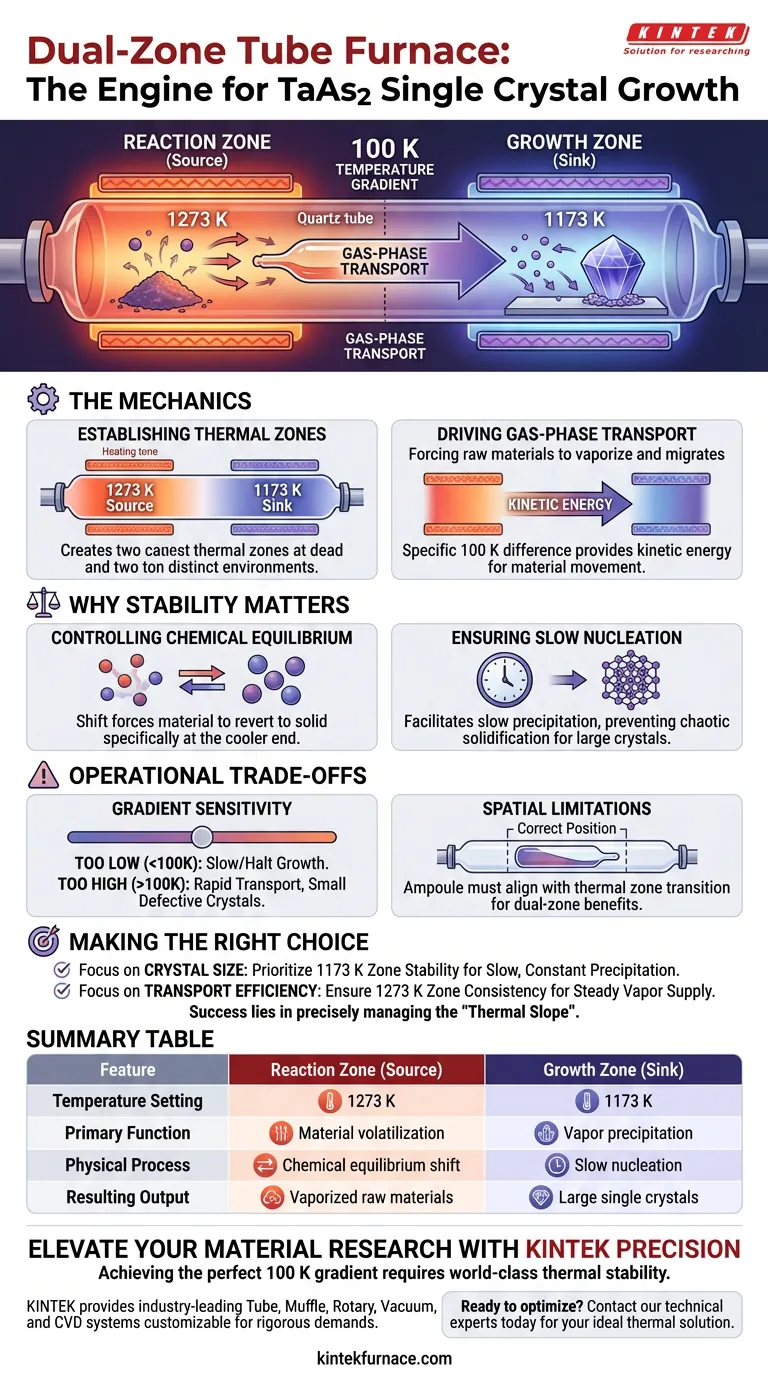

The primary role of a dual-zone tube furnace in the growth of TaAs2 single crystals is to establish and maintain a precise 100 K temperature gradient. By holding the reaction zone at 1273 K and the growth zone at 1173 K, the furnace acts as the engine for gas-phase transport, utilizing this thermal difference to drive the chemical equilibrium shifts required for crystallization.

The dual-zone furnace functions as a thermodynamic driver, creating a stable differential between a hot source and a cooler sink to force volatile components to migrate and precipitate slowly, yielding large, high-quality crystals.

The Mechanics of the Temperature Gradient

Establishing Thermal Zones

The furnace creates two distinct thermal environments within a single sealed system.

According to the specific requirements for TaAs2, the "source" or reaction zone is heated to 1273 K, while the "sink" or growth zone is maintained at 1173 K.

Driving Gas-Phase Transport

This specific 100 K temperature difference is not arbitrary; it provides the kinetic energy necessary to transport materials.

The gradient causes the raw materials to react and vaporize in the hotter zone, moving naturally toward the cooler region. Without this dual-zone control, the material would remain static, and transport would not occur.

Why Stability Matters for Crystal Quality

Controlling Chemical Equilibrium

The furnace allows for the manipulation of chemical equilibrium shifts.

As the vaporized components move from the 1273 K zone to the 1173 K zone, the change in temperature shifts the equilibrium, forcing the material to revert to a solid state. This is the fundamental mechanism that allows TaAs2 to deposit specifically at the cooler end of the tube.

Ensuring Slow Nucleation

High-quality single crystals require time to form an orderly lattice structure.

The dual-zone furnace facilitates slow precipitation, which prevents the chaotic, rapid solidification that leads to polycrystals or defects. This controlled rate of growth is directly responsible for the formation of large-sized single crystals.

Understanding the Operational Trade-offs

Gradient Sensitivity

While the dual-zone setup offers precision, it introduces sensitivity to thermal fluctuations.

If the temperature difference drops significantly below 100 K, the transport rate may slow to a halt, stopping growth entirely. Conversely, an excessive gradient could induce transport that is too rapid, resulting in smaller, defect-ridden crystals rather than large single crystals.

Spatial Limitations

The distinct zones imply a physical limit on the size of the reaction and growth areas.

The user must ensure the ampoule or tube is positioned exactly where the thermal zones transition. Misalignment of the tube within the furnace can result in the growth zone being too hot or too cold, negating the benefits of the dual-zone control.

Making the Right Choice for Your Goal

To maximize the effectiveness of a dual-zone tube furnace for TaAs2 growth, consider these focal points:

- If your primary focus is Crystal Size: Prioritize the stability of the 1173 K zone to ensure the precipitation rate remains slow and constant over the entire growth period.

- If your primary focus is Transport Efficiency: Ensure the reaction zone maintains a consistent 1273 K to fully volatilize the source material without fluctuating, which ensures a steady supply of vapor to the growth zone.

Success in growing TaAs2 lies not just in heating the material, but in precisely managing the "thermal slope" between the two zones.

Summary Table:

| Feature | Reaction Zone (Source) | Growth Zone (Sink) |

|---|---|---|

| Temperature Setting | 1273 K | 1173 K |

| Primary Function | Material volatilization | Vapor precipitation |

| Physical Process | Chemical equilibrium shift | Slow nucleation |

| Resulting Output | Vaporized raw materials | Large single crystals |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect 100 K gradient for TaAs2 single crystal growth requires world-class thermal stability. KINTEK provides industry-leading Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of advanced material science.

Backed by expert R&D and precision manufacturing, our high-temperature furnaces are fully customizable to your unique research specifications, ensuring slow nucleation and defect-free crystallization every time.

Ready to optimize your crystal growth process? Contact our technical experts today to find the ideal thermal solution for your laboratory.

Visual Guide

References

- Haiyao Hu, Claudia Felser. Multipocket synergy towards high thermoelectric performance in topological semimetal TaAs2. DOI: 10.1038/s41467-024-55490-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the quartz tube furnace minimize heat loss? Double Insulation for Energy Efficiency

- What role does a tube furnace play in the pyrolysis of oil shale? Mastering Kerogen Conversion & Yield

- How does a dual-zone horizontal tube furnace provide the conditions for CVT? Optimize Single Crystal Growth

- What are the primary functions of a tube furnace for ZIF-derived materials? Optimize Carbonization & Porosity

- What is the primary role of a Tube Furnace in g-C3N4 synthesis? Achieve Precise Thermal Polycondensation

- What is the working environment of a vacuum tube furnace? Achieve Purity and Precision in Material Processing

- What advantages do three-zone furnaces offer? Achieve Superior Temperature Control and Efficiency

- What protective role does a wet hydrogen (Ar/H2) environment play in a tube furnace for thin film stability testing?