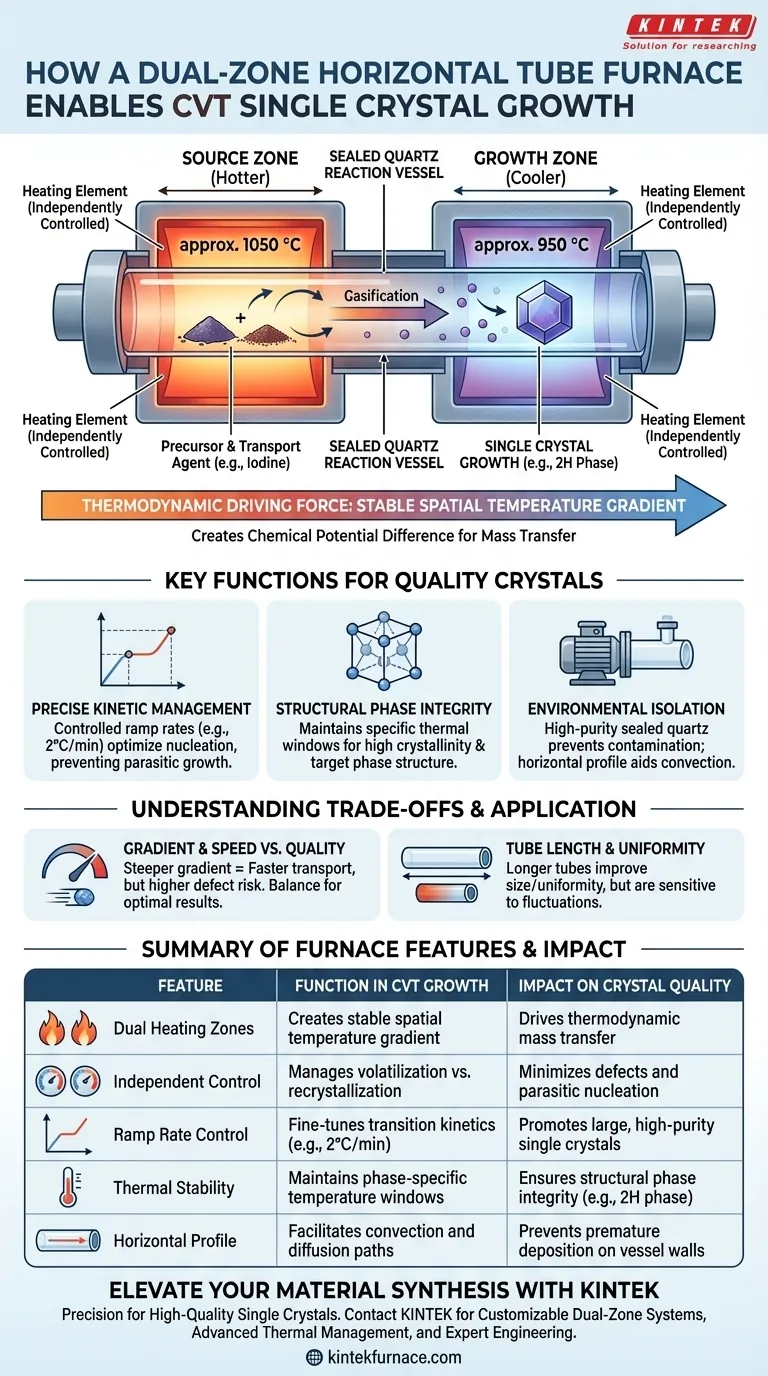

A dual-zone horizontal tube furnace enables Chemical Vapor Transport (CVT) by establishing a precise, stable temperature gradient that serves as the thermodynamic driving force for material movement. By maintaining a hotter source zone (typically near 1050 °C) and a cooler growth zone (around 950 °C), the furnace facilitates the volatilization of precursors and their subsequent recrystallization into high-quality single crystals.

The dual-zone furnace acts as a controlled engine for mass transfer, utilizing a spatial temperature differential to drive gaseous transport species from a high-energy source to a lower-energy growth site. This precise thermal management is the critical factor in determining crystal nucleation, growth rate, and structural phase purity.

Establishing the Thermodynamic Driving Force

The Role of the Spatial Temperature Gradient

The primary function of the dual-zone configuration is to create a stable temperature differential across a sealed reaction vessel. In a typical CVT setup, the source material is placed in the hot zone, while the target crystals form in the cold zone.

This gradient creates a chemical potential difference, forcing gaseous transport agents (like iodine) to carry the source material through the vapor phase. Without this specific spatial separation, the material would remain in equilibrium, and no net transport or growth would occur.

Precise Control of Vapor Phase Movement

By independently controlling two heating elements, the furnace maintains the specific kinetics required for gas-phase chemical reactions. As the transport agent reacts with the solid precursor in the source zone, it forms volatile species that migrate toward the growth zone.

Once these species reach the lower temperature of the growth zone, the chemical reaction reverses or the solubility changes. This causes the material to desublimate or precipitate out of the gas phase, depositing atom-by-atom onto the crystal lattice.

Kinetic Management and Crystal Quality

Optimizing Nucleation via Transition Rates

Modern dual-zone furnaces allow for highly specific temperature transition rates, such as a controlled ramp of 2 °C per minute. This fine-tuning is essential during the initial stages of growth to prevent "parasitic nucleation," where too many small crystals form simultaneously.

Slow, deliberate cooling ensures that only a few high-quality nuclei form, allowing the remaining material to contribute to the growth of large, hexagonal flake single crystals. Rapid fluctuations in temperature would otherwise lead to defects or polycrystalline formations.

Maintaining Structural Phase Integrity

Specific materials require precise thermal windows to achieve the desired phase structure, such as the 2H phase in certain van der Waals crystals. The dual-zone furnace provides the thermal stability necessary to keep the growth environment within these narrow parameters.

Consistency in the growth zone temperature ensures that the resulting crystals exhibit high crystallinity. This predictability is vital for producing materials with consistent electronic or optical properties.

The Role of the Reaction Environment

Environmental Isolation via Quartz Vessels

While the furnace provides the heat, it operates in tandem with a high-purity quartz sealed tube. This tube serves as a vacuum-sealed reaction vessel that prevents external oxygen or moisture from contaminating the process.

The quartz vessel is specifically chosen for its ability to withstand the extreme temperatures (often 600 °C to 1050 °C) required for CVT. This isolation ensures that the only chemistry occurring is between the intended precursors and the transport agents.

Facilitating Vacuum-Based Recrystallization

The furnace must provide a uniform heating profile around the quartz tube to ensure that recrystallization occurs only at the intended growth site. If the furnace has "cold spots" outside the growth zone, the material may deposit prematurely on the tube walls.

A horizontal orientation helps maintain a clear path for convection and diffusion within the tube. This setup allows the transport agents to cycle continuously between the source and growth zones until the precursor is exhausted.

Understanding the Trade-offs

Gradient Stability vs. Growth Speed

A steeper temperature gradient generally increases the transport rate, leading to faster crystal growth. However, excessive speed often results in lower crystal quality and a higher density of structural defects.

Tube Length and Thermal Uniformity

Longer quartz tubes allow for a more gradual gradient, which can improve crystal size, but they are more susceptible to thermal fluctuations. Shorter tubes offer better temperature control but may limit the total yield of the growth run.

Material Compatibility with Transport Agents

The choice of transport agent (e.g., Iodine) must be perfectly matched to the furnace's temperature capabilities. If the furnace cannot reach the volatilization temperature of the specific metal-halide intermediate, no transport will occur regardless of the gradient.

How to Apply This to Your Project

Recommendations for Implementation

- If your primary focus is Maximum Crystal Size: Utilize a very shallow temperature gradient (e.g., 50 °C difference) and an extremely slow cooling rate to prioritize single-nucleus growth.

- If your primary focus is Phase Purity: Rigorously calibrate the growth zone temperature to the specific thermodynamic stability window of your target phase (e.g., the 2H phase).

- If your primary focus is High Throughput: Increase the source zone temperature to the maximum safe limit of your quartz vessel to accelerate the volatilization of precursors.

Successful CVT growth depends entirely on the furnace’s ability to transform a static chemical environment into a dynamic, temperature-driven transport system.

Summary Table:

| Feature | Function in CVT Growth | Impact on Crystal Quality |

|---|---|---|

| Dual Heating Zones | Creates a stable spatial temperature gradient | Drives thermodynamic mass transfer |

| Independent Control | Manages volatilization vs. recrystallization rates | Minimizes defects and parasitic nucleation |

| Ramp Rate Control | Fine-tunes transition kinetics (e.g., 2°C/min) | Promotes large, high-purity single crystals |

| Thermal Stability | Maintains phase-specific temperature windows | Ensures structural phase integrity (e.g., 2H phase) |

| Horizontal Profile | Facilitates convection and diffusion paths | Prevents premature deposition on vessel walls |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between a polycrystalline mess and a high-quality single crystal. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Tube, Muffle, Rotary, Vacuum, and CVD systems designed to meet the rigorous demands of Chemical Vapor Transport (CVT).

Why choose KINTEK for your lab?

- Customizable Dual-Zone Systems: Tailored thermal gradients for specific van der Waals crystals.

- Advanced Thermal Management: Achieve the exact kinetics needed for phase-pure growth.

- Expert Engineering: Our high-temp furnaces are built for stability, reliability, and precision.

Ready to optimize your crystal growth parameters? Contact KINTEK today to discuss your unique research needs with our technical team!

Visual Guide

References

- Bhupendra Mor, Kirti Korot. Comparative optical response and structural assessment of MoS₂ and MoSe₂ single crystals grown via iodine-assisted chemical vapor transport. DOI: 10.33545/26647575.2025.v7.i2a.168

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is the importance of the calcination process using a tube resistance furnace? Optimize Boron Catalyst Activation

- What are the technical considerations for using quartz tubes for sulfidation? Optimize Your Material Purity & Stability

- What types of atmospheric conditions can tubular furnaces operate under? Master Precise Control for Material Synthesis

- How does a Vertical Fluidized Bed Furnace ensure reaction stability? Key Mechanisms for Sulfur Oxidation Experiments

- How does a high-temperature tube furnace contribute to the post-deposition processing of Ge:ZnO thin films?

- What are the technical advantages of using a three-zone tube furnace? Boost SnSe Thin Film Quality

- Why is high-precision temperature control in a tube furnace critical for rhenium catalysts? Ensure Optimal Alumina Calcination

- What are the options for zonal heating in horizontal tube furnaces? Optimize Your Thermal Control