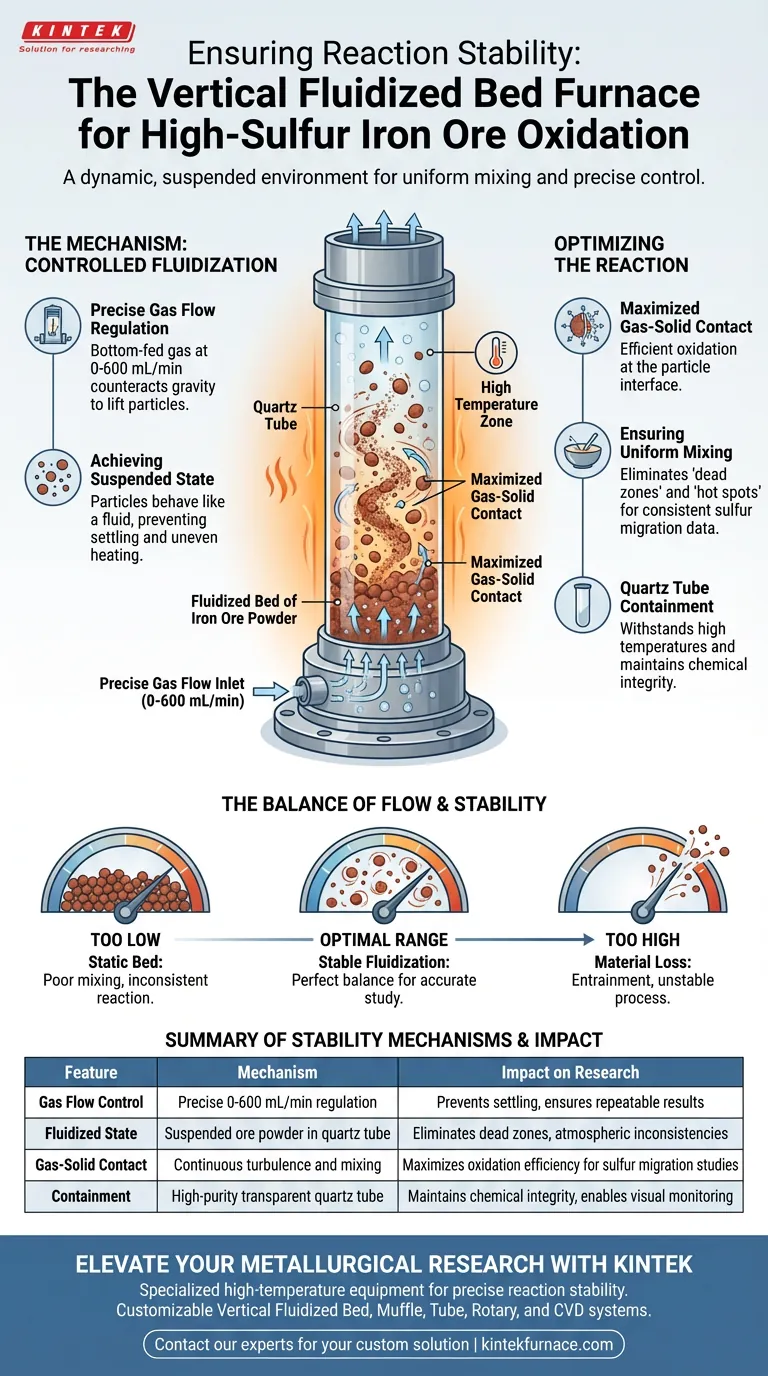

The Vertical Fluidized Bed Furnace ensures reaction stability by creating a dynamic, suspended environment where ore powder and reactant gases mix uniformly. By introducing gas from the bottom of a transparent quartz tube at precisely controlled rates—typically between 0 to 600 mL/min—the system achieves a fluidized state that maximizes gas-solid contact and eliminates atmospheric inconsistencies.

The core advantage of this apparatus is its ability to transform a static solid reaction into a fluid-like process. This ensures that every particle of high-sulfur iron ore is exposed to identical conditions, a critical requirement for accurately studying the migration laws of sulfur elements.

The Mechanics of Controlled Fluidization

Precise Gas Flow Regulation

The stability of the reaction hinges on the rigorous control of gas flow. Gas is introduced from the bottom of the furnace to counteract the gravity acting on the ore powder.

Operators typically adjust this flow within a specific range of 0 to 600 mL/min. This precision allows the user to dial in the exact velocity required to lift the specific particle size of the ore being tested.

Achieving the Suspended State

When the gas flow is optimized, the ore powder enters a suspended fluidized state. The particles do not settle at the bottom, nor are they blown out of the tube.

This suspension allows the solid particles to behave like a fluid. It prevents the material from packing down, which often leads to uneven heating and inconsistent reactions in static furnaces.

Optimizing the Reaction Environment

Maximizing Gas-Solid Contact

In oxidation roasting, the reaction occurs at the interface between the solid ore and the oxygen in the gas. The fluidized bed ensures sufficient contact between these two phases.

Because the particles are constantly moving and surrounded by gas, the oxidation process is far more efficient than in setups where gas simply passes over a stationary bed of material.

Ensuring Uniform Mixing

The turbulence created by the fluidization results in uniform mixing of the reactants. This homogeneity eliminates "dead zones" where reactions might stall or "hot spots" where temperatures might spike uncontrollably.

For researchers studying sulfur migration, this uniformity is non-negotiable. It guarantees that the data collected reflects the chemical properties of the ore, rather than artifacts of an uneven experimental setup.

The Quartz Tube Containment

The core reaction zone is housed within a transparent quartz tube. This material is chosen for its ability to withstand high temperatures and chemical attack.

It provides a contained, clean environment that maintains the atmospheric integrity required for sensitive high-sulfur experiments.

Common Challenges and Trade-offs

Sensitivity to Flow Rate

While the 0-600 mL/min range offers flexibility, it requires careful calibration. Flow rates that are too low will fail to fluidize the bed, resulting in a static reaction with poor mixing.

Conversely, flow rates that are too high can entrain solids, blowing the ore powder out of the reaction zone entirely. The stability of the experiment relies entirely on finding the precise equilibrium within this range.

Making the Right Choice for Your Goal

To maximize the effectiveness of a Vertical Fluidized Bed Furnace for your specific research, consider the following experimental priorities:

- If your primary focus is studying Sulfur Migration: Prioritize uniform mixing to ensure that the atmospheric conditions surrounding the sulfur are constant throughout the timeline.

- If your primary focus is Oxidation Efficiency: Focus on maximizing gas-solid contact by adjusting the flow rate to the upper limit of the stable fluidization regime without causing material loss.

By mastering the balance between gas flow and particle suspension, you ensure the high-fidelity data necessary to understand complex metallurgical reactions.

Summary Table:

| Feature | Mechanism for Stability | Impact on Research |

|---|---|---|

| Gas Flow Control | Precise 0-600 mL/min regulation | Prevents settling and ensures repeatable results |

| Fluidized State | Suspended ore powder in quartz tube | Eliminates dead zones and atmospheric inconsistencies |

| Gas-Solid Contact | Continuous turbulence and mixing | Maximizes oxidation efficiency for sulfur migration studies |

| Containment | High-purity transparent quartz tube | Maintains chemical integrity and enables visual monitoring |

Elevate Your Metallurgical Research with KINTEK

Precise reaction stability is the foundation of accurate material analysis. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vertical Fluidized Bed Furnaces, Muffle, Tube, Rotary, and CVD systems, all customizable to meet your unique laboratory requirements.

Whether you are investigating sulfur migration laws or optimizing oxidation efficiency, our specialized high-temperature equipment provides the uniform environment your research demands.

Ready to optimize your lab's thermal processing? Contact our experts today to find your custom solution.

Visual Guide

References

- Xiaojiao Chen, Zijian Wang. Study on the Migration and Release of Sulfur during the Oxidizing Roasting of High-Sulfur Iron Ore. DOI: 10.3390/min14030276

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What critical conditions does a high-temperature tube furnace provide for Ti–Nb–Si alloys? Master Sintering Success

- What are the key design features of a split tube furnace? Unlock Superior Access for Complex Experiments

- Why is the first stage of sintering in a tube vacuum sintering furnace necessary? Master the Space-Holder Technique

- How does the hydrogen reduction process in a laboratory tube furnace facilitate the exsolution of nickel species?

- What is the purpose of using an industrial-grade vertical tube furnace in phosphorus recovery? High-Fidelity Simulation

- Why must a tube furnace used for the pyrolysis of tungsten-based nanocomposites be equipped with a precision gas flow?

- Why is a high-performance tube furnace required for chemical activation? Achieve Precision Pore Control at 700°C

- In what settings are both tube and box furnaces commonly used? Optimize Your Thermal Processes with the Right Choice