At its core, a split tube furnace is defined by its two-half, hinged construction. This design allows the entire furnace chamber to be opened lengthwise, providing direct and unobstructed access to the interior. Unlike standard tube furnaces that require samples to be slid in from one end, this feature is specifically engineered for handling large samples or complex experimental setups that are already assembled.

The defining feature of a split tube furnace is its hinged body, which prioritizes accessibility for complex, in-situ experiments over the simpler design of a solid tube furnace. This choice fundamentally shapes its operational advantages and limitations.

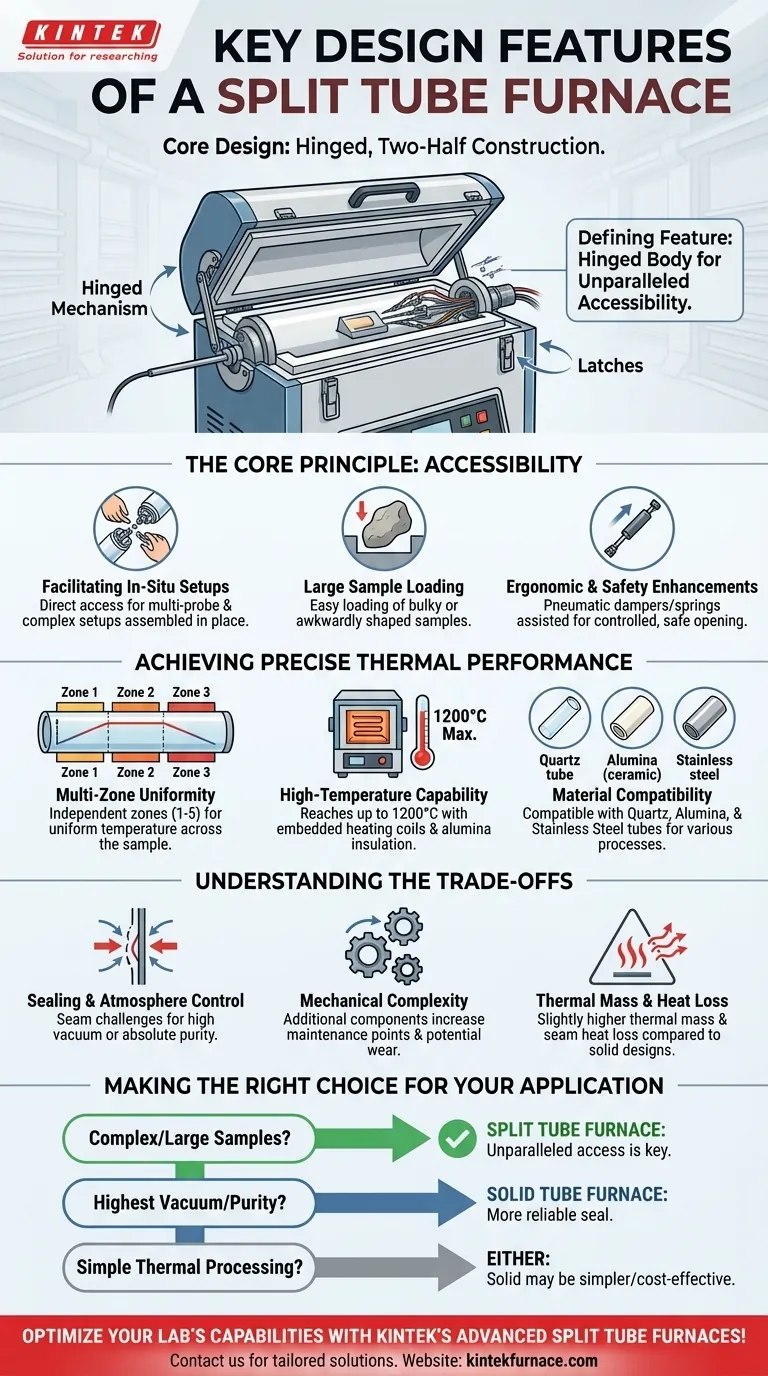

The Core Principle: Unparalleled Accessibility

The primary reason to choose a split tube furnace is for ease of access. This single design choice enables several key operational benefits not possible with a solid, one-piece furnace.

The Hinged, Two-Half Construction

A split tube furnace consists of a cylindrical heating chamber that is literally split into two semi-cylindrical halves. These halves are connected by robust hinges on one side and latches on the other.

This mechanical design allows the top half of the furnace to be lifted away, completely exposing the internal work tube and the sample within it.

Facilitating In-Situ Setups

The ability to open the chamber is critical for experiments where the apparatus cannot be easily inserted from the end of a tube. This includes setups with multiple probes, complex wiring, or delicate components that must be assembled in place.

It also dramatically simplifies the loading and unloading of large or irregularly shaped samples that would be difficult or impossible to manage in a conventional tube furnace.

Ergonomic and Safety Enhancements

Due to the significant weight of the insulated furnace halves, these systems are often equipped with pneumatic dampening struts or spring-loaded mechanisms.

These components assist in the smooth and controlled opening and closing of the furnace, preventing it from slamming shut and ensuring operator safety.

Achieving Precise Thermal Performance

While accessibility is its main selling point, a split tube furnace is also a high-performance tool designed for precise thermal control in research and industrial settings.

Multi-Zone Uniformity

To ensure a highly uniform temperature across the sample, these furnaces are often available with multiple heating zones (commonly 1, 2, 3, or even 5 zones). Each zone is independently controlled, allowing the system to compensate for heat loss at the ends and maintain a consistent thermal profile.

High-Temperature Capability

Split tube furnaces are engineered for high-temperature work, often reaching a maximum of 1200°C. This is achieved using durable heating coils embedded within a high-purity fibrous alumina insulation.

For safety and energy efficiency, the furnace body uses a dual-layer steel casing with forced air cooling to keep the external surface temperature safe to the touch.

Material Compatibility

The design is compatible with various process tube materials, including quartz, alumina (ceramic), and stainless steel. This allows you to select a tube based on your experiment's specific temperature requirements and chemical compatibility.

Understanding the Trade-offs

The unique design of a split tube furnace introduces specific trade-offs that are important to consider.

Sealing and Atmosphere Control

The seam between the two halves creates a potential point of failure for achieving a perfect seal. While well-designed furnaces minimize this, attaining an extremely high vacuum or ensuring absolute atmospheric purity can be more challenging than in a solid, one-piece tube furnace.

Mechanical Complexity

The addition of hinges, latches, and assisted-opening struts introduces mechanical complexity. These components represent additional maintenance points and potential sources of wear and tear over the furnace's operational life compared to a simpler, solid furnace.

Thermal Mass and Heat Loss

By nature, the split design can have a slightly larger thermal mass and may experience marginally greater heat loss along the seam compared to a perfectly sealed, compact solid furnace. This can have minor implications for heat-up/cool-down rates and overall energy efficiency.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on the demands of your specific process or experiment.

- If your primary focus is complex, in-situ experiments or large samples: The unparalleled access of a split tube furnace is its most compelling advantage.

- If your primary focus is achieving the highest possible vacuum or atmosphere purity: A solid (non-split) tube furnace often provides a more reliable and robust seal.

- If your primary focus is simple thermal processing of granular or powder samples: Either furnace type will perform well, but a solid tube furnace may offer a simpler, more cost-effective solution.

Ultimately, choosing the right furnace means matching its core design strengths to your most critical operational needs.

Summary Table:

| Feature | Description |

|---|---|

| Hinged Two-Half Construction | Allows full chamber opening for direct access to samples and setups. |

| Multi-Zone Heating | Independent temperature control for uniform thermal profiles. |

| High-Temperature Capability | Reaches up to 1200°C with durable insulation and cooling systems. |

| Material Compatibility | Supports quartz, alumina, and stainless steel tubes for varied experiments. |

| Accessibility Benefits | Ideal for large, irregular samples and in-situ experiments with probes. |

| Trade-offs | Challenges include sealing for atmospheres, mechanical complexity, and heat loss. |

Optimize your lab's capabilities with KINTEK's advanced split tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is enhanced by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our split tube furnaces can deliver precise thermal control and unparalleled accessibility for your complex setups!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control