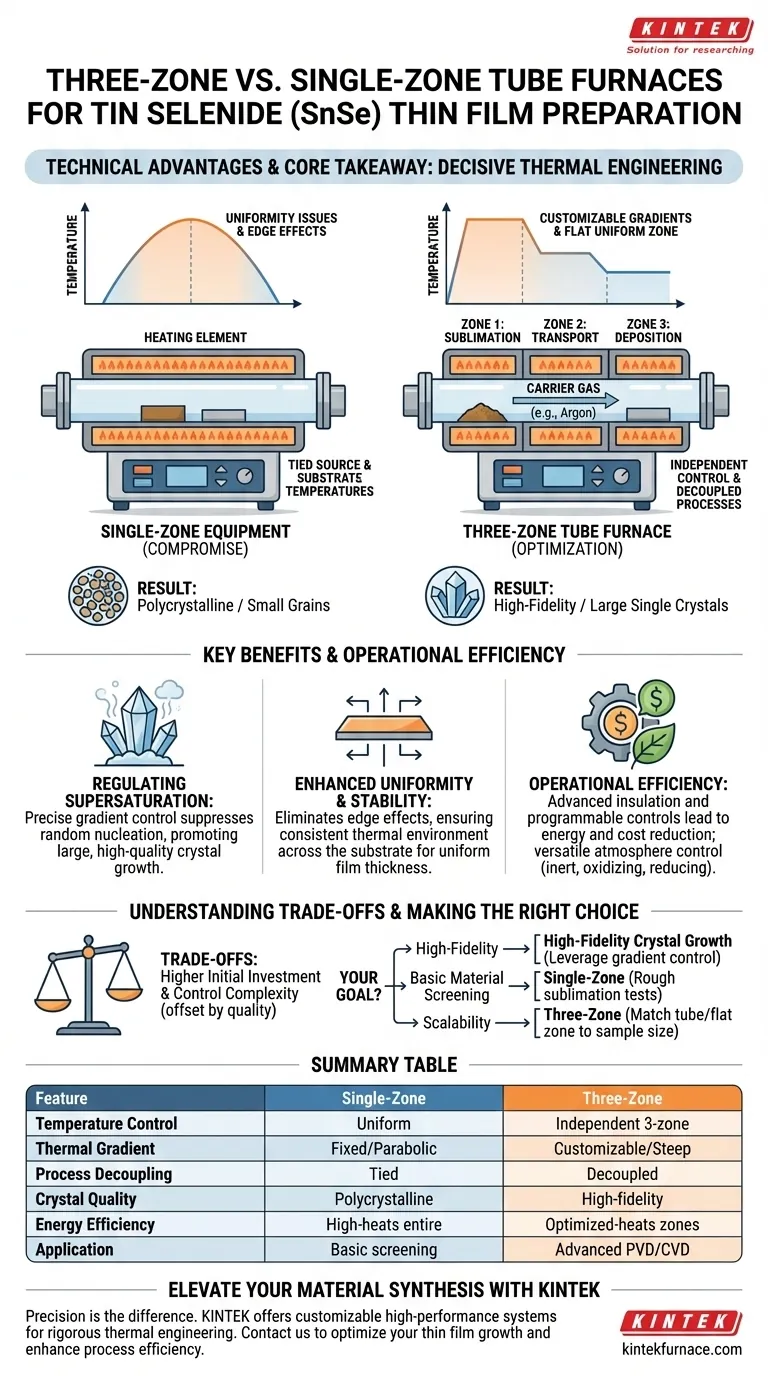

The primary technical advantage of a three-zone tube furnace is its ability to create and sustain distinct, independent thermal environments within a single processing tube. While single-zone equipment forces a compromise between source and substrate temperatures, a three-zone configuration allows you to decouple the sublimation zone from the deposition zone, optimizing both simultaneously for Tin Selenide (SnSe) preparation.

Core Takeaway: The superior performance of three-zone furnaces in Tin Selenide synthesis stems from the precise regulation of supersaturation levels. By independently controlling the temperature gradient between the raw material and the substrate, you can suppress random nucleation and promote the growth of large-sized, high-quality crystals.

Decoupling the PVD Process

Independent Optimization

In Physical Vapor Deposition (PVD), the conditions required to sublime the raw material differ significantly from those required for deposition.

A three-zone furnace allows you to set a high temperature in the upstream zone to sublime the SnSe powder effectively. Simultaneously, you can maintain a lower, precisely controlled temperature in the downstream zone where the substrate resides.

Regulating Supersaturation

The quality of SnSe crystals is heavily dependent on the supersaturation of the vapor at the growth site.

If supersaturation is too high, too many nuclei form, resulting in small, polycrystalline films. The three-zone system allows you to fine-tune the thermal gradient to keep supersaturation in the ideal range, facilitating the growth of larger, single-crystalline domains.

Transport Control

The central zone often acts as a transition or buffer area.

By utilizing a stable carrier gas flow (such as Argon) through these controlled zones, gas-phase components are transported from the high-temperature sublimation zone to the lower-temperature deposition zone with high predictability.

Enhanced Uniformity and Stability

Eliminating Edge Effects

Single-zone furnaces often suffer from thermal drop-offs at the edges of the heating element, creating a parabolic temperature profile.

Three-zone configurations compensate for this by actively heating the ends of the tube. This ensures that the central "flat zone" is significantly longer and more uniform, minimizing temperature deviation along the sample’s length.

Sensitivity Management

Tin Selenide growth is sensitive to minor thermal fluctuations.

The enhanced uniformity of a three-zone system ensures that the substrate experiences a consistent thermal environment across its entire surface. This prevents uneven film thickness or structural defects caused by localized hot or cold spots.

Operational Efficiency

Energy and Cost Reduction

Modern three-zone furnaces are designed with advanced insulation and programmable controls.

By heating only the necessary zones to peak temperatures and utilizing rapid heating/cooling capabilities, these systems often result in lower operational costs compared to maintaining a massive single zone at peak output.

Versatility in Atmosphere

These furnaces are generally designed to accommodate various atmospheric conditions, including inert, oxidizing, or reducing gas flows.

This versatility allows for the precise tuning of the reaction environment, which is critical when trying to prevent the oxidation of Tin Selenide during the high-temperature growth phase.

Understanding the Trade-offs

Complexity of Control

With three independent heating elements come three independent PID control loops.

Operators must understand how the zones interact; heat from one zone can bleed into adjacent zones. Achieving a perfect gradient requires more sophisticated calibration and recipe development than a simple "set and forget" single-zone system.

Higher Initial Investment

The hardware required for three-zone control (extra thermocouples, power controllers, and heating elements) increases the upfront cost.

However, for applications requiring high-quality SnSe thin films, this cost is usually offset by the reduction in failed batches and the improved quality of the final material.

Making the Right Choice for Your Goal

To select the correct equipment for your SnSe thin film project, consider your primary objective:

- If your primary focus is High-Fidelity Crystal Growth: Prioritize a three-zone system to leverage gradient control for maximizing crystal size and minimizing defects.

- If your primary focus is Basic Material Screening: A single-zone furnace may suffice for rough sublimation tests where crystal size and uniformity are not critical performance metrics.

- If your primary focus is Scalability: Ensure the three-zone furnace has a tube diameter and flat zone length that matches your target wafer or sample size.

Ultimately, the move to a three-zone furnace is a move from simple heating to precise thermal engineering, giving you the control necessary to dictate the structure of your material.

Summary Table:

| Feature | Single-Zone Tube Furnace | Three-Zone Tube Furnace |

|---|---|---|

| Temperature Control | Uniform across entire zone | Independent control of 3 distinct zones |

| Thermal Gradient | Fixed/Parabolic | Customizable and steep gradients |

| Process Decoupling | Source and substrate tied | Decoupled (Sublimation vs. Deposition) |

| Crystal Quality | Polycrystalline/Small grains | High-fidelity/Large single crystals |

| Energy Efficiency | High (heats entire tube) | Optimized (heats specific zones) |

| Application | Basic screening & testing | Advanced PVD & CVD synthesis |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between a failed batch and a breakthrough. At KINTEK, we understand that advanced materials like Tin Selenide (SnSe) demand rigorous thermal engineering.

Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems. Our three-zone tube furnaces are fully customizable to provide the exact thermal gradients and atmosphere control your research requires.

Ready to optimize your thin film growth? Contact us today to discuss your unique needs and see how our lab solutions can enhance your process efficiency.

Visual Guide

References

- Liang-Yao Huang, Kung‐Hsuan Lin. Anisotropy of Second‐Harmonic Generation in SnSe Flakes with Ferroelectric Stacking. DOI: 10.1002/adpr.202500033

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the main operational considerations when using a lab tube furnace? Ensure Precision and Safety in Your Experiments

- How does a laboratory tube furnace ensure the structural stability and quality of hard carbon? Expert Carbonization

- How is a High Temperature Tube Furnace used in material science? Unlock Precise Material Synthesis & Control

- Why is a high-precision tube furnace necessary for YIG thin films? Unlock Superior Magnetic Performance

- What is a tube furnace and its main characteristics? Discover Precision Heating for Your Lab

- How does a programmable tube furnace facilitate Al/SiC material transformation? Precision Heat for Ceramic Coatings

- What is the function of autoclaves and tube reactors in hydrometallurgical leaching? Unlock Refractory Ore Potential

- What factors should be considered when selecting a tube furnace? Choose the Right Furnace for Your Lab Needs