In material science, a high-temperature tube furnace is a foundational tool for synthesizing new materials, purifying compounds, and precisely modifying the properties of existing substances. Its core function is to provide a highly controlled environment where materials can be subjected to extreme heat, often in a specific atmosphere or a vacuum, to achieve a desired chemical or physical transformation.

At its heart, a tube furnace is not just an oven; it is a controlled reaction chamber. Its value lies in the ability to precisely manage both temperature and atmosphere, giving scientists and engineers the power to build, alter, and test materials at a fundamental level.

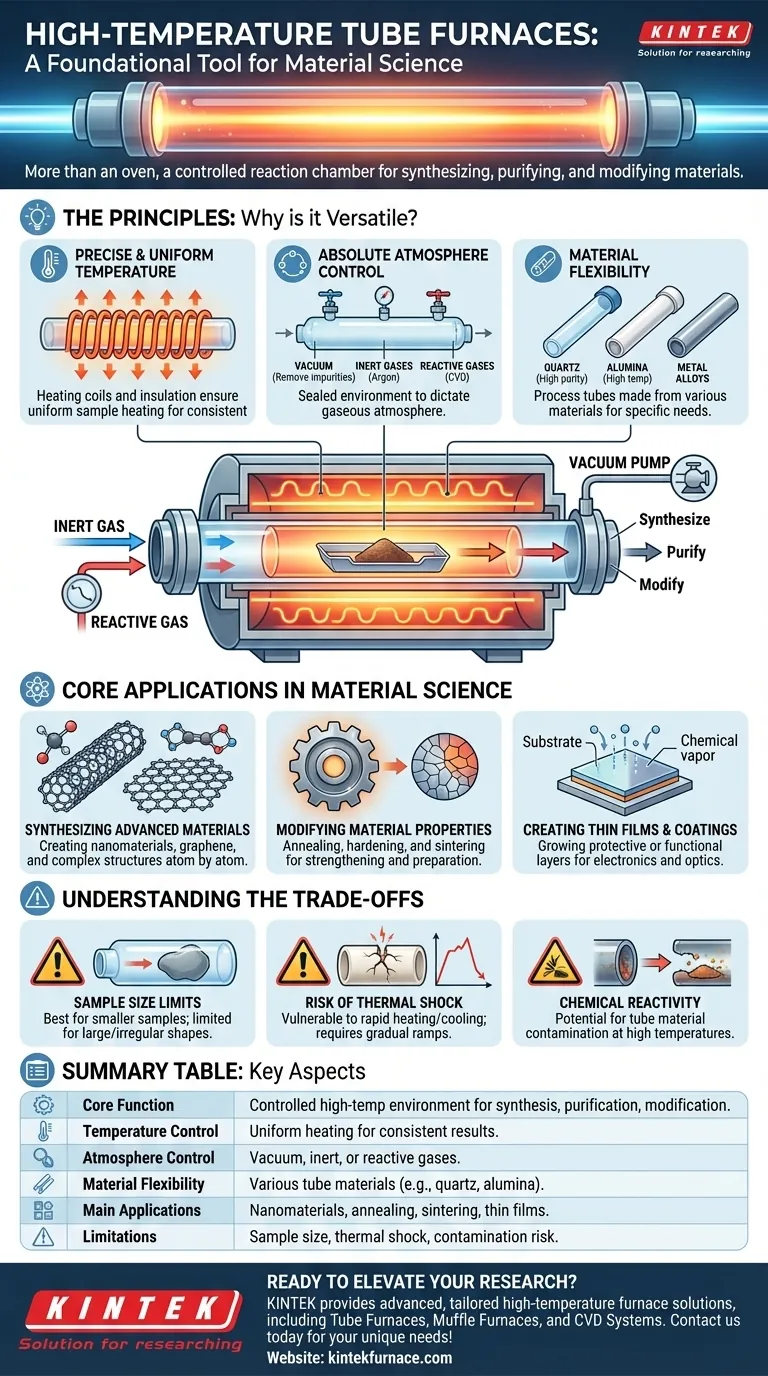

The Principle: Why is a Tube Furnace So Versatile?

The power of a tube furnace comes from its ability to isolate a sample and control its environment with extreme precision. This control is based on a few key principles.

Precise and Uniform Temperature Control

A tube furnace uses heating coils, often wrapped completely around the central process tube. This design, combined with high-grade thermal insulation, ensures the sample is heated uniformly from all sides.

This uniformity is critical for processes where every part of the sample must experience the exact same conditions to yield consistent results.

Absolute Atmosphere Control

The sealed tube design allows operators to dictate the exact gaseous environment. Samples can be heated in a vacuum to remove impurities or prevent oxidation.

Alternatively, specific inert gases (like argon) can be introduced to create a non-reactive environment, or reactive gases can be used to intentionally create new compounds or surface layers, a process known as chemical vapor deposition.

Material and Process Flexibility

The process tube itself can be made from different materials, such as quartz, alumina, or metal alloys.

Choosing the right tube is essential. Quartz is excellent for purity and observation but has temperature limits, while alumina can withstand much higher temperatures and is ideal for many high-temperature synthesis and sintering processes.

Core Applications in Material Science

This precise environmental control unlocks a wide range of applications, from fundamental research to the production of cutting-edge materials.

Synthesizing Advanced Materials

Tube furnaces are central to creating materials that do not exist in nature. This includes the synthesis of nanomaterials, graphene, and carbon nanotubes.

The controlled atmosphere and high heat provide the necessary energy and environment to assemble these complex structures atom by atom or molecule by molecule.

Modifying Material Properties

Heat treatment is a classic metallurgical technique used to change a material's physical properties. Tube furnaces offer the precision needed for advanced versions of these processes.

Annealing (softening and relieving internal stress), hardening, and sintering (fusing powders into a solid mass) are all performed in tube furnaces to strengthen materials or prepare them for specific applications.

Creating Thin Films and Coatings

The ability to introduce reactive gases makes the tube furnace ideal for growing thin films on a substrate.

This is used for everything from creating protective, corrosion-resistant coatings on wires to depositing functional layers for electronic or optical components.

Understanding the Trade-offs

While incredibly powerful, the tube furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Sample Size and Geometry Limitations

The most obvious limitation is the diameter of the tube. Tube furnaces are best suited for smaller samples or batch processes. They are generally not practical for processing very large or irregularly shaped objects.

Risk of Thermal Shock

Process tubes, especially those made of ceramic or quartz, are vulnerable to thermal shock. Heating or cooling the furnace too quickly can cause the tube to crack, ruining the experiment and requiring costly replacement. Gradual temperature ramps are essential.

Chemical Reactivity and Contamination

At very high temperatures, even seemingly inert tube materials can react with the sample. This can introduce impurities that contaminate the final product. Researchers must carefully match the tube material to the chemicals and temperatures being used to ensure process purity.

Matching the Furnace to Your Research Goal

To leverage a tube furnace effectively, you must align its capabilities with your specific objective.

- If your primary focus is synthesizing high-purity materials: Your choice of an inert tube material (like high-purity alumina) and the ability to achieve a deep vacuum are the most critical factors.

- If your primary focus is thermal treatment like annealing: Your top priorities are uniform heating across the entire sample length and a programmable controller for precise cooling rates.

- If your primary focus is creating coatings or films: The ability to accurately control gas flow rates and mixtures is just as important as temperature control.

Ultimately, the high-temperature tube furnace is an indispensable instrument that enables the deliberate and precise manipulation of matter.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Function | Provides controlled high-temperature environments for material synthesis, purification, and property modification. |

| Temperature Control | Ensures uniform heating with precise management for consistent results. |

| Atmosphere Control | Allows operation in vacuum, inert gases, or reactive gases to prevent oxidation or enable reactions. |

| Material Flexibility | Supports various tube materials (e.g., quartz, alumina) for different temperature and purity needs. |

| Main Applications | Synthesis of nanomaterials, annealing, sintering, and thin film deposition via chemical vapor processes. |

| Limitations | Sample size constraints, risk of thermal shock, and potential chemical contamination at high temperatures. |

Ready to elevate your material science research with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for laboratories like yours. Our product line, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to meet your unique experimental needs with strong deep customization capabilities. Whether you're synthesizing nanomaterials, performing heat treatments, or depositing thin films, KINTEK furnaces deliver the control and consistency you demand. Contact us today to discuss how we can support your specific applications and drive your innovations forward!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?