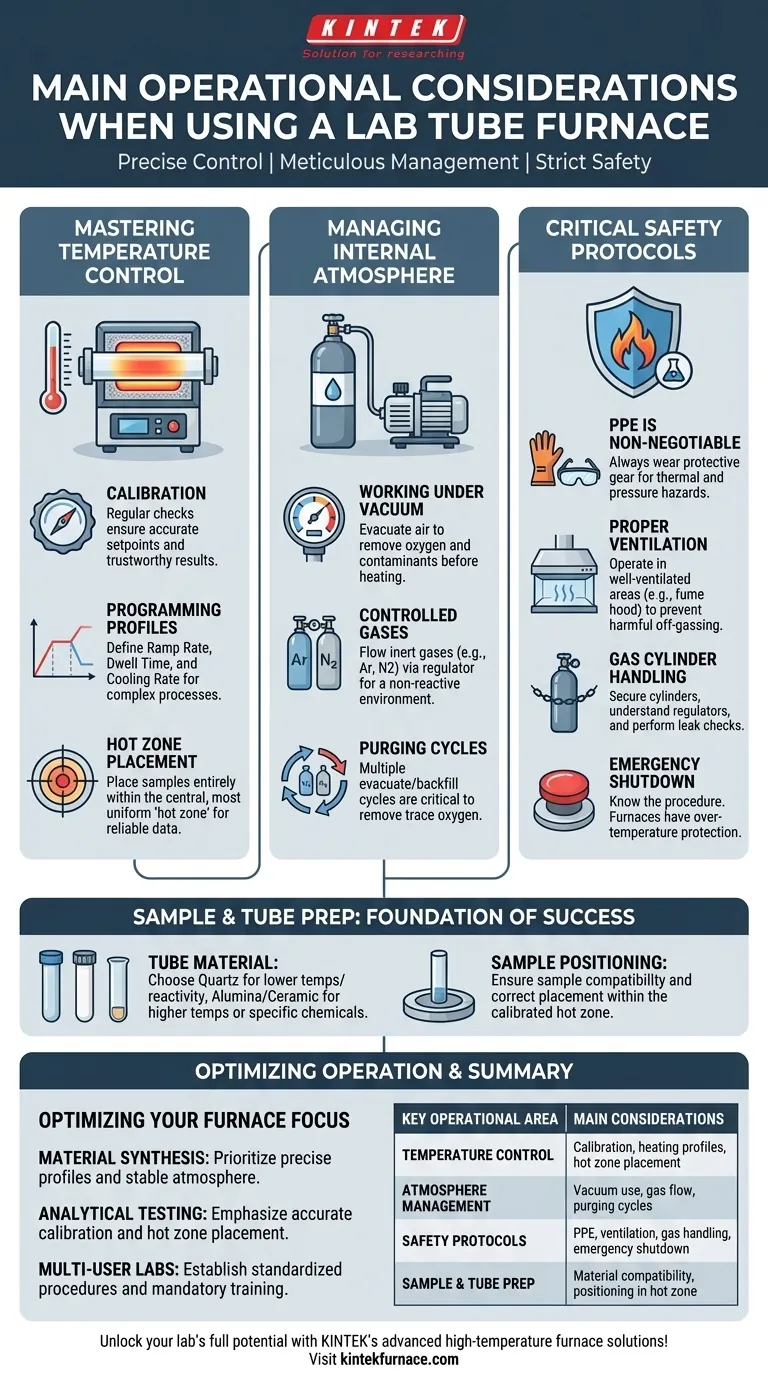

Operating a lab tube furnace centers on three critical pillars: precise control over temperature, meticulous management of the internal atmosphere, and strict adherence to safety protocols. These elements work in concert to ensure both the integrity of your experimental results and the well-being of the operator.

A tube furnace is more than just a heating element; it's a precision instrument for creating a controlled environment. Successful operation hinges on understanding the interplay between your sample, the furnace materials, the atmosphere, and the temperature profile—all while prioritizing operator safety above all else.

Mastering Temperature Control for Repeatable Results

The primary function of a tube furnace is to apply heat accurately. Flawless temperature management is the difference between a successful experiment and unusable data.

The Importance of Calibration

A furnace's temperature display is only as reliable as its last calibration. Regular calibration against a certified thermocouple ensures your setpoints are accurate and your results are trustworthy.

Programming the Temperature Profile

Modern furnaces allow for complex heating profiles. This includes the ramp rate (how fast it heats up), the dwell time (how long it stays at a target temperature), and the cooling rate. Properly programming these phases is essential for processes like annealing or crystal growth.

Understanding Temperature Uniformity

No furnace is perfectly uniform. There is always a central "hot zone" where the temperature is most stable and accurate. For reliable results, your sample must be placed entirely within this zone.

Managing the Internal Atmosphere

Many advanced material processes cannot occur in the presence of oxygen. A tube furnace excels at creating a controlled, non-ambient atmosphere.

Working Under Vacuum

A common first step is to use a vacuum pump to remove the ambient air from the process tube. This evacuates oxygen and other contaminants before heating or introducing a specific gas.

Introducing Controlled Gases

After creating a vacuum, an inert gas like argon or nitrogen can be flowed through the tube. This creates a stable, non-reactive environment. The gas source is typically a high-pressure cylinder connected via a regulator to control the flow rate.

Ensuring Atmosphere Purity

Simply flowing a gas is not enough. Most procedures require several cycles of evacuating the tube (pulling a vacuum) and backfilling it with the desired gas. This "purging" process is critical for removing trace amounts of residual oxygen.

Sample and Tube Preparation: The Foundation of Success

What happens inside the furnace tube is paramount. The interaction between your sample and its immediate environment dictates the outcome.

Choosing the Right Tube Material

The process tube is the heart of the system. Quartz tubes are common but have temperature and reactivity limitations. Alumina or other ceramic tubes are used for higher temperatures or when reacting with specific chemicals. Sample compatibility is a primary consideration.

Preparing and Positioning Your Sample

The sample must be compatible with the process temperature and atmosphere. It must also be placed correctly within the furnace's calibrated hot zone to ensure it experiences the intended thermal profile.

Understanding the Critical Safety Protocols

The high temperatures and controlled atmospheres of a tube furnace introduce significant hazards. Ignoring safety is not an option.

Personal Protective Equipment (PPE) is Non-Negotiable

Always wear heat-resistant gloves when handling any part of the furnace or removing samples. Safety glasses are mandatory to protect against thermal or pressure-related incidents.

Ensuring Proper Ventilation

Many processes can release harmful or toxic off-gasses. The furnace must be operated in a well-ventilated area, often under a chemical fume hood, to prevent the buildup of hazardous fumes.

Handling High-Pressure Gas Cylinders

Gas cylinders must be securely chained to a wall or stable fixture. Operators must be trained in the proper use of pressure regulators and how to perform leak checks on all fittings to prevent dangerous gas leaks.

Knowing Emergency Shutdown Procedures

Every operator must be familiar with the emergency shutdown procedure. Modern furnaces have built-in over-temperature protection to prevent thermal runaway, but manual intervention may still be required.

Optimizing Your Furnace Operation

To use your furnace effectively, align your operational focus with your experimental goal.

- If your primary focus is material synthesis (e.g., annealing, sintering): Prioritize precise temperature profile control and maintaining a pure, stable atmosphere over long durations.

- If your primary focus is analytical testing (e.g., thermal decomposition): Emphasize extremely accurate temperature calibration and ensuring the sample is placed perfectly within the uniform hot zone for repeatable data.

- If you are managing a multi-user lab: Your top priority is establishing and enforcing standardized operating and safety procedures, including mandatory training and clear shutdown protocols.

By treating the tube furnace as a complete system rather than just a heat source, you unlock its full potential for reliable and insightful results.

Summary Table:

| Key Operational Area | Main Considerations |

|---|---|

| Temperature Control | Calibration, heating profiles, hot zone placement |

| Atmosphere Management | Vacuum use, gas flow, purging cycles |

| Safety Protocols | PPE, ventilation, gas handling, emergency shutdown |

| Sample and Tube Prep | Material compatibility, positioning in hot zone |

Unlock the full potential of your lab with KINTEK's advanced high-temperature furnace solutions! We specialize in Tube Furnaces and other systems like Muffle, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong R&D and in-house manufacturing ensure deep customization to meet your unique experimental needs—whether for material synthesis, analytical testing, or multi-user labs. Contact us today to discuss how we can enhance your precision, safety, and efficiency!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents