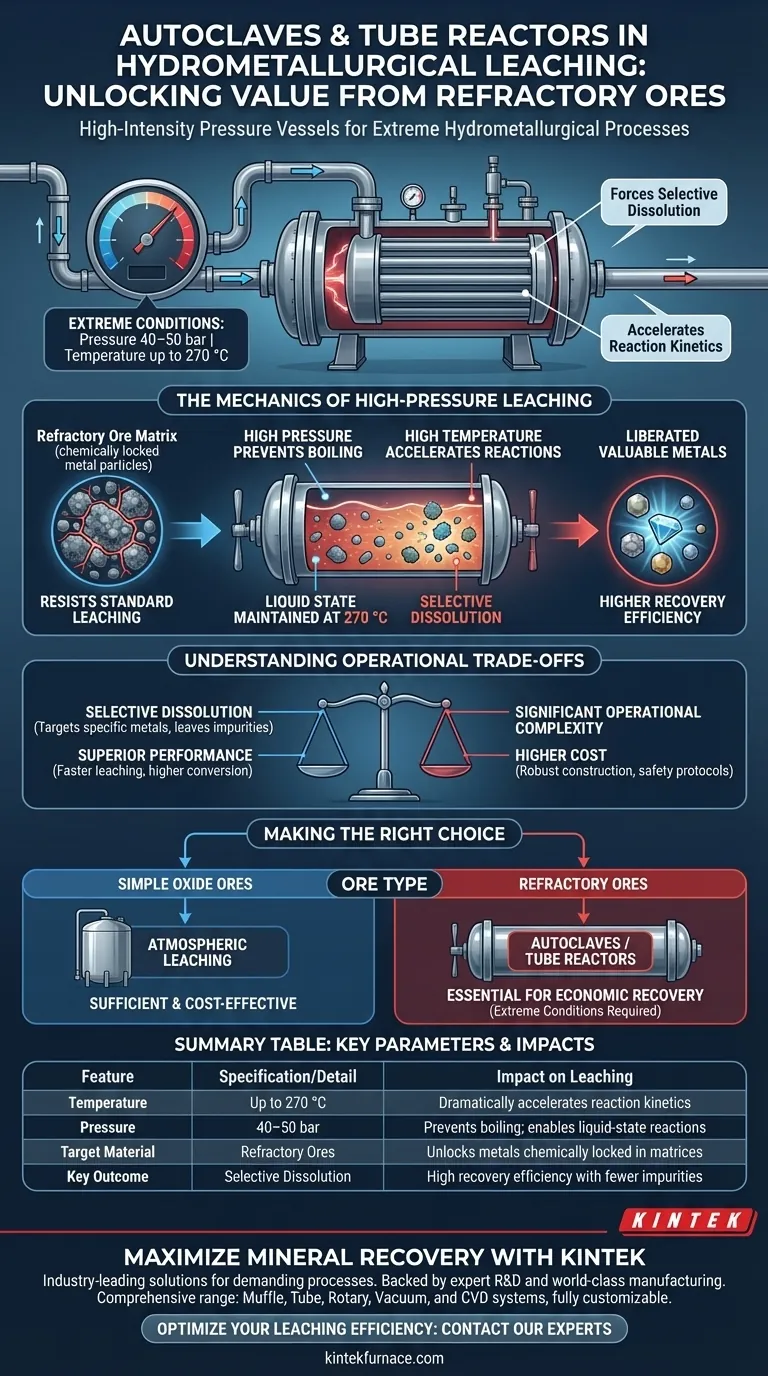

Autoclaves and tube reactors function as high-intensity pressure vessels designed to facilitate hydrometallurgical processes that are impossible under standard atmospheric conditions. Their primary role is to generate and maintain extreme environments—specifically pressures of 40–50 bar and temperatures up to 270 °C—to force the selective dissolution of target metals from complex ores.

By elevating temperature and pressure far beyond atmospheric limits, these reactors dramatically accelerate reaction kinetics, unlocking valuable metals from "refractory" ores that resist standard leaching methods.

The Mechanics of High-Pressure Leaching

Targeting Refractory Ores

Many mineral deposits are classified as refractory, meaning the valuable metal is chemically locked within a matrix that resists standard processing.

Simple atmospheric leaching is often too slow or chemically insufficient to liberate these metals. Autoclaves and tube reactors are engineered specifically to overcome this resistance by subjecting the slurry to aggressive chemical environments.

The Role of Temperature and Pressure

To achieve the necessary chemical conversion, reaction temperatures must reach as high as 270 °C.

At this temperature, liquid solutions would normally boil away instantly. To prevent this, these vessels maintain high pressures of 40–50 bar, keeping the solution in a liquid state and allowing the chemical leaching process to proceed at highly accelerated rates.

Enhancing Chemical Conversion

The combination of high heat and pressure does more than just melt rock; it fundamentally changes the reaction kinetics.

These conditions significantly increase the leaching rate, reducing the time required to extract the metal. Furthermore, they improve the overall conversion efficiency, ensuring a higher percentage of the target metal is recovered from the host rock.

Understanding the Operational Trade-offs

The Cost of Extreme Conditions

While these systems offer superior performance, they introduce significant operational complexity compared to atmospheric tanks.

The requirement to maintain 40–50 bar of pressure necessitates robust, expensive vessel construction and specialized safety protocols.

Selectivity vs. Complexity

The primary advantage of using these reactors is selective dissolution, allowing operators to target specific metals while leaving impurities behind.

However, achieving this selectivity requires precise control over the temperature and pressure profile. Deviations from the optimal 270 °C or pressure drop can lead to stalled reactions or the co-dissolution of unwanted contaminants.

Making the Right Choice for Your Goal

These systems are high-performance tools designed for specific mineralogical challenges.

- If your primary focus is processing simple oxide ores: Avoid these high-pressure systems, as standard atmospheric leaching is sufficient and far more cost-effective.

- If your primary focus is recovering metals from refractory ores: You must utilize autoclaves or tube reactors to achieve the extreme conditions (up to 270 °C) required for economic recovery rates.

High-pressure leaching is the definitive solution for maximizing yield from difficult-to-process mineral deposits.

Summary Table:

| Feature | Specification/Detail | Impact on Leaching |

|---|---|---|

| Temperature | Up to 270 °C | Dramatically accelerates reaction kinetics |

| Pressure | 40–50 bar | Prevents boiling; enables liquid-state reactions |

| Target Material | Refractory Ores | Unlocks metals chemically locked in matrices |

| Key Outcome | Selective Dissolution | High recovery efficiency with fewer impurities |

Maximize Your Mineral Recovery with KINTEK

Don't let refractory ores limit your yield. KINTEK provides industry-leading high-temperature and high-pressure solutions tailored for the most demanding hydrometallurgical processes. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific laboratory or industrial needs.

Ready to optimize your leaching efficiency? Contact our technical experts today to design a high-performance system that delivers the precision and durability your project requires.

Visual Guide

References

- Srečko Stopić. Feature Papers in Extractive Metallurgy. DOI: 10.3390/met15070751

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does a tube furnace facilitate the structural stabilization of lignin? Mastering Lignin-to-Carbon Transformation

- What role does sodium hypophosphite (NaH2PO2) play in a tube furnace for NCMCP? Master Precise Phosphidation

- Why is a high-temperature tube furnace required for MoS2 and WS2 thin films? Achieve 2H Crystalline Phase Excellence

- Why is vacuum sealing of a reaction tube necessary during the in-situ solvothermal growth of BiVO4/COF?

- What role does a laboratory tube furnace system play in the catalytic pyrolysis of LLDPE? Enhancing Yield and Precision

- Why is tube furnace temperature control critical for anhydrous rare earth halide powders? Achieve Precise Synthesis

- What materials are commonly used for the heating element in tubular furnaces? Choose the Best for Your High-Temp Needs

- How is a laboratory tube furnace utilized to convert metal-organic precursors? Master Thin Film Pyrolysis Today