The working environment of a vacuum tube furnace is defined by its ability to create a highly controlled, isolated atmosphere. This environment is achieved within a sealed tube, typically made of quartz or corundum. By using a vacuum pump system, the furnace removes reactive gases like oxygen and nitrogen to create a vacuum, or alternatively, allows for the introduction of specific inert gases to create a custom atmosphere for material processing.

A vacuum tube furnace isn't just about creating a vacuum; it's about achieving absolute atmospheric control. This control is the key to preventing unwanted oxidation and contamination, enabling high-purity material processing at extreme temperatures.

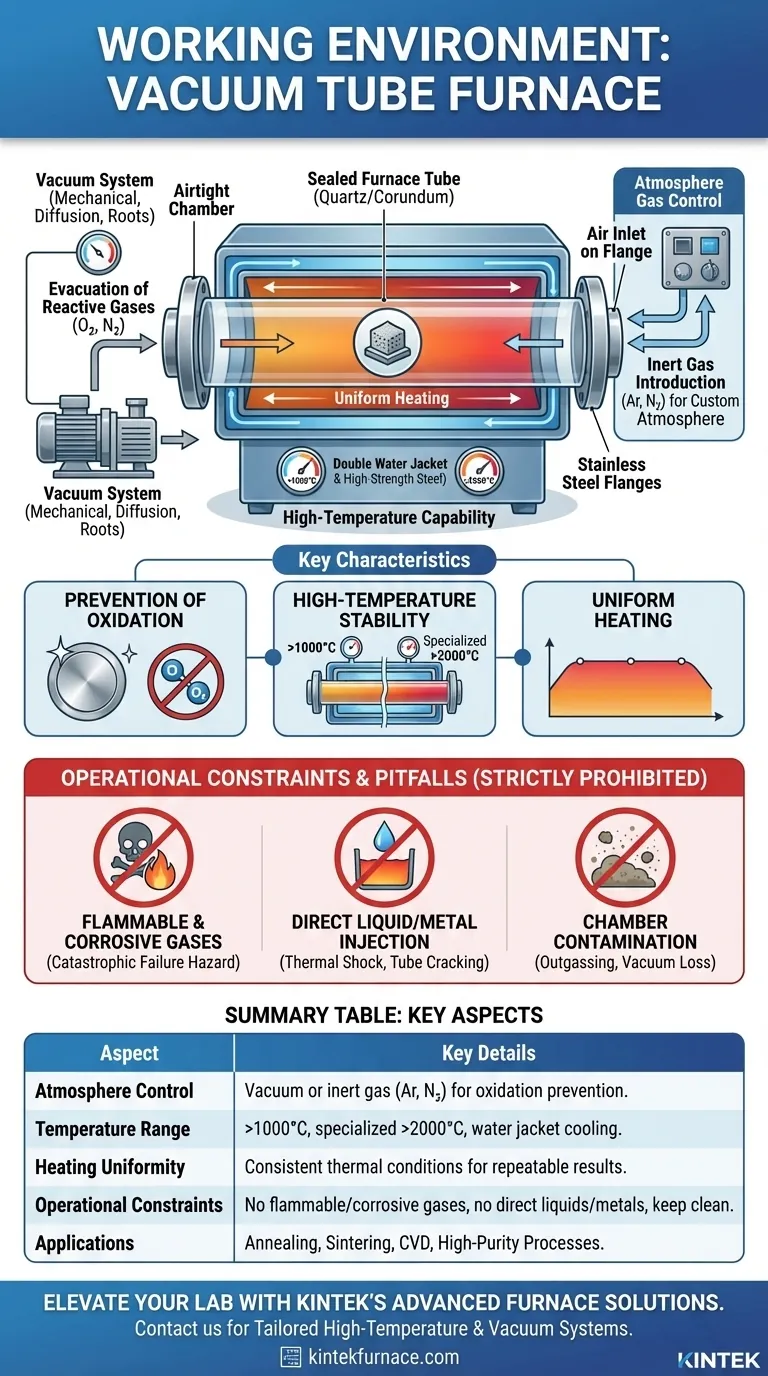

How the Controlled Atmosphere is Achieved

The environment inside a vacuum tube furnace is not passive; it is actively created and maintained through a combination of physical barriers and specialized equipment.

The Sealed Furnace Tube

The core of the furnace is a sealed container, usually a horizontal tube made from materials like quartz or corundum that can withstand high temperatures.

This tube is sealed at both ends with stainless steel flanges, creating an airtight chamber. This design allows for the easy placement and removal of materials while ensuring the internal atmosphere remains isolated from the outside air.

The Vacuum System

To create a vacuum, the furnace is connected to a vacuum pump system. This system evacuates the air and other gases from inside the sealed tube.

Depending on the required level of vacuum, the system may include a mechanical pump, a diffusion pump, or a Roots pump. High-performance systems can achieve a maximum vacuum degree of 7 × 10⁻³ Pa, a near-perfect vacuum.

Atmosphere Gas Control

The working environment is not limited to a vacuum. A dedicated air inlet on the flange allows for precise control over the internal atmosphere.

Operators can either evacuate the tube to create a vacuum or introduce a specific gas or gas mixture, such as argon or nitrogen. This flexibility is critical for processes like annealing, sintering, or chemical vapor deposition.

Key Characteristics of the Operating Environment

The controlled atmosphere enables several critical operational characteristics that define the furnace's utility.

Prevention of Oxidation

The primary purpose of controlling the atmosphere is to prevent the materials inside from reacting with air. Removing oxygen and moisture stops oxidation and other unwanted chemical changes, preserving the material's original properties.

High-Temperature Capability

The furnace body is typically a double water jacket structure made from high-strength steel. This cooling system protects the furnace shell and sealing components, allowing for sustained, stable operation at temperatures exceeding 1000°C, with some specialized models going above 2000°C.

Uniform Heating

The tube-based design promotes uniform heating along its length. This ensures that the entire sample is subjected to the same thermal conditions, which is crucial for consistent and repeatable experimental results.

Common Pitfalls and Operational Constraints

To maintain the integrity of the furnace and the purity of the process, you must adhere to strict operational rules. Missteps can damage the equipment and compromise your results.

Prohibition of Flammable and Corrosive Gases

The working environment must be kept entirely free of flammable and corrosive gases. Introducing such substances can cause catastrophic failure of the furnace components and create significant safety hazards.

No Direct Injection of Liquids or Metals

Directly injecting liquids or molten metal into the hot furnace chamber is strictly prohibited. The extreme temperature difference can cause thermal shock, cracking the furnace tube and leading to a loss of vacuum and potential equipment damage.

Maintaining Chamber Cleanliness

The furnace chamber must be kept clean at all times. Any residue, dust, or contamination left from previous runs can outgas during the heating process, spoiling the vacuum and contaminating the new sample.

Making the Right Choice for Your Process

Understanding the furnace's environment empowers you to tailor its use to your specific goal.

- If your primary focus is material purity: Your top priority is achieving the highest possible vacuum and ensuring the chamber is impeccably clean before every run.

- If your primary focus is a specific chemical reaction: Your attention should be on the precise control and flow rate of the custom gas mixture you introduce into the chamber.

- If your primary focus is process repeatability: You must standardize your procedures for evacuation, heating, and cooling to ensure consistent thermal and atmospheric conditions every time.

Ultimately, mastering the environment of a vacuum tube furnace is mastering the outcome of your work.

Summary Table:

| Aspect | Key Details |

|---|---|

| Atmosphere Control | Vacuum or inert gas (e.g., argon, nitrogen) for oxidation prevention and contamination-free processing |

| Temperature Range | Exceeds 1000°C, with specialized models over 2000°C, enabled by double water jacket cooling |

| Heating Uniformity | Uniform heating along tube length ensures consistent and repeatable experimental results |

| Operational Constraints | Avoid flammable/corrosive gases, no direct liquid/metal injection, maintain chamber cleanliness |

| Applications | Annealing, sintering, chemical vapor deposition, and other high-purity material processes |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions!

Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable vacuum tube furnaces, muffle furnaces, tube furnaces, rotary furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering enhanced purity, precision, and efficiency.

Contact us today to discuss how our tailored solutions can optimize your material processing and drive your research forward!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency