Tube Furnace

High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

Item Number : KT-PTF

Price varies based on specs and customizations

- Max. temperature

- 1100℃

- Rated positive pressure

- 15 Mpa (at ambient temp), 4 Mpa (at 800°C)

- Temperature control accuracy

- ±1℃

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

KINTEK High Pressure Tube Furnace

KINTEK's High Pressure Tube Furnace is a specialized system designed for advanced material processing in diverse industries, including metallurgy, glass, heat treatment, and cutting-edge laboratory research. Engineered for reliability and precision, this furnace allows for operations under controlled high-pressure atmospheres or high vacuum conditions, making it ideal for processes like powder sintering, crystal growth, and material testing under extreme environments. It ensures sample integrity by preventing contamination, supported by high-quality heating elements and precise control systems.

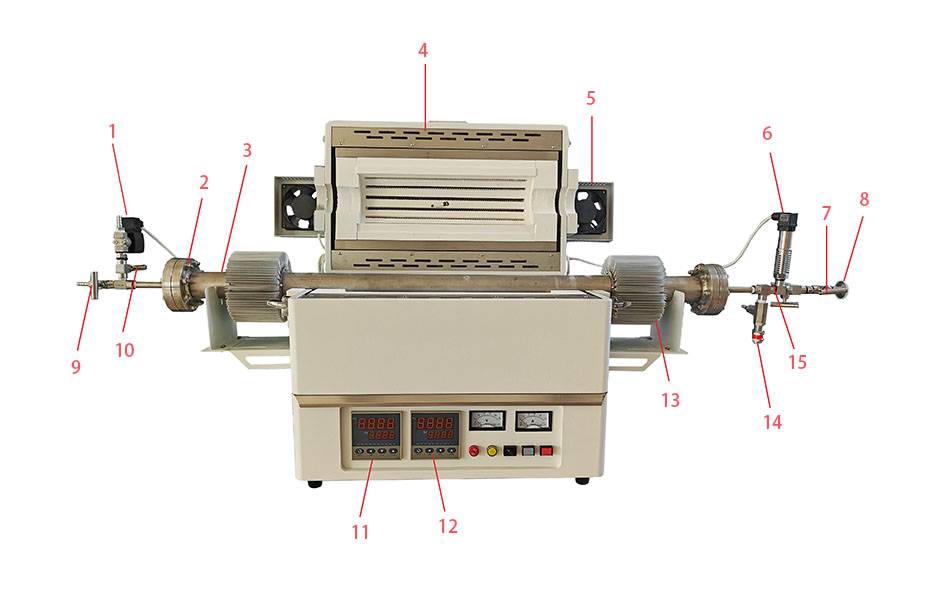

Detail & Parts

Engineered for Precision, Reliability, and Safety

Our High Pressure Tube Furnaces are designed with cutting-edge features to deliver exceptional performance and meet rigorous experimental demands:

- Robust Performance Under Extreme Conditions:

- Operate with confidence using positive pressures up to 15Mpa at ambient temperature (4Mpa at 800°C).

- Achieve working temperatures up to 1100°C, thanks to the durable high-temperature nickel-based super alloy furnace tube.

- Precise Control & Versatility:

- Maintain process integrity with versatile atmosphere control, supporting both controlled atmospheres (including flammable gases) and high vacuum conditions (up to 10E-5 torr).

- Benefit from sophisticated gas distribution technology for accurate control of atmosphere dew point.

- Ensure accurate temperature regulation with PID programmable control (±1℃ accuracy) and stable heating.

- Precisely manage pressure with a digital positive pressure meter, featuring over-pressure alarming.

- The PTF Pro model offers an advanced 7-inch TFT touch screen controller for intuitive program setting, history data analysis, multi-program presets, and power failure restarting functionality.

- Supports remote control and centralized control for convenient operation and monitoring.

- Multiple independently controlled temperature zones allow for precise heating and cooling profiles (customizable).

- Enhanced Safety & Durability:

- Automatic pressure release system activates when the set pressure value is reached, preventing over-pressurization.

- Comprehensive safety features include over-current protection, over-temperature alarming, and automatic power-off.

- Built-in thermocouple break detection stops heating and triggers an alarm if failure is detected.

- The furnace tube flange seal employs a solid copper O-ring, adapting to both negative and positive pressures for extended service life.

- A double furnace shell design with forced air cooling keeps the furnace surface temperature low, enhancing operator safety and comfort.

- Ease of Use & Maintenance:

- Modular construction facilitates straightforward maintenance and replacement of parts, minimizing downtime.

Versatile Applications

The KT-PTF High Pressure Tube Furnace is indispensable for a wide range of applications across various industries and research fields:

- Annealing: Soften materials, improve machinability, and relieve internal stresses.

- Brazing: Join metals by melting a filler metal into the joint under controlled conditions.

- Calcining: Process minerals and ores to remove volatile substances.

- Ceramics: Essential for firing and sintering advanced ceramic materials.

- Cleaning: Effective for thermal cleaning of parts and materials.

- Crystal Growth: Facilitate the controlled growth of high-quality crystals.

- Firing: Critical for hardening materials in the ceramic and glass industries.

- Glass Processing: Used in the production and shaping of specialized glass products.

- Gradient Work: Create materials with varying compositions or properties.

- Heat Treating: Enhance the mechanical properties of metals and alloys under specific atmospheres.

- Laboratory Research: Provide a precisely controlled environment for diverse scientific experiments.

- Materials Testing: Evaluate material properties and behaviors under high temperatures and pressures.

- Melting: Ideal for melting metals and alloys for casting or further processing.

- Powder Metallurgy: Process metal and ceramic powders, including sintering under pressure.

Advanced Operating Principle

The High Pressure Tube Furnace operates under a controlled atmosphere or high vacuum conditions. It utilizes a high-temperature nickel-based super alloy furnace tube designed to withstand both high temperatures (up to 1100°C) and significant pressures (up to 15 Mpa at ambient temperature, 4 Mpa at 800°C). The integrity of the system is ensured by a robust furnace tube flange seal using a solid copper O-ring, suitable for both negative and positive pressure applications, ensuring longevity and reliable performance.

Technical Specifications

| Furnace model | KT-PTF | KT-PTF Pro |

| Temperature controller | Digital PID controller | Touch screen PID controller |

| Multi program preset | no | yes |

| Power failure restarting | no | yes |

| Max. temperature | 1100℃ | |

| Constant work temperature | 1000℃ | |

| Furnace tube material | Super nickel based alloy | |

| Furnace tube diameter | 50 / 60 / 80 / 100 mm (Customizable) | |

| Heating zone length | 300 / 450 / 600 / 800 mm (Customizable) | |

| Heating zone quantity | 1-10 zones (Customizable) | |

| Vacuum sealing solution | SS 304 flange with solid copper seal ring | |

| Rated vacuum pressure | 0.001Pa/10E-5 torr | |

| Rated positive pressure | 15 Mpa (at ambient temp), 4 Mpa (at 800°C) | |

| Chamber material | Japan Al2O3 alumina fiber | |

| Heating element | Cr2Al2Mo2 wire coil | |

| Temperature sensor | Built-in K type Thermocouple | |

| Temperature control accuracy | ±1℃ | |

| Temperature uniformity | ±5℃ (in constant temperature zone) | |

| Electric power supply | AC110-220V, 50/60HZ (Customizable) | |

| Other super nickel based alloy tube sizes and heating zone lengths can be customized. | ||

Standard Package

| No. | Description | Quantity |

| 1 | Furnace Main Body | 1 |

| 2 | High-Pressure Alloy Tube | 1 |

| 3 | Vacuum Flanges with Gas/Vacuum Ports & Pressure Gauge | 2 sets |

| 4 | Tube Thermal Blocks/Plugs | 2 |

| 5 | Tube Thermal Block Hook | 1 |

| 6 | Heat Resistant Gloves | 1 pair |

| 7 | Operation Manual | 1 |

Note: Package contents may vary slightly based on model and customization. An alumina tube is typically included for non-pressure or lower-pressure applications if specified.

Optional Setups for Enhanced Functionality

- In-tube gas detecting and monitoring systems (e.g., for H2, O2).

- Independent furnace temperature monitoring and recording capabilities.

- RS 485 communication port for PC remote control and data exporting.

- Precise control of inert gas feeding flow rates using mass flowmeters or float flowmeters.

- Upgrades to different models of touch screen temperature controllers with versatile operator-friendly functions.

- Comprehensive high vacuum pump station setups, including vane vacuum pumps, molecular pumps, or diffusion pumps.

Why Partner with KINTEK for Your High-Temperature Needs?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and industries with advanced high-temperature furnace solutions. Our extensive product line, including Muffle Furnaces, Tube Furnaces (like this High Pressure model), Rotary Furnaces, Vacuum & Atmosphere Furnaces, and specialized CVD/PECVD/MPCVD Systems, is backed by our strong deep customization capability. We are committed to precisely meeting your unique experimental and production requirements, ensuring you receive a furnace that perfectly aligns with your application needs.

Request Your Custom High Pressure Tube Furnace Solution

Ready to elevate your research or industrial processes with a high-performance High Pressure Tube Furnace? Discuss your specific requirements with our experienced engineers. We specialize in tailoring solutions to meet your exact needs, from tube dimensions and heating zones to advanced control features.

Contact us today for a personalized consultation and quote! Fill out the form below or click here to jump to our contact form.

FAQ

What Is A Tube Furnace And How Does It Work?

What Are The Main Applications Of A Vacuum Furnace?

What Is A Vacuum Induction Furnace?

What Is The Principle Of A Hot Press Furnace?

What Is An Atmosphere Furnace Used For?

What Are The Common Applications Of A Split Tube Furnace?

What Are The Main Applications Of A Rotary Tube Furnace?

What Are The Main Applications Of Multi-zone Tube Furnaces?

What Are The Main Applications Of Tube Furnaces?

What Are The Key Features Of A Vacuum Furnace?

What Are The Main Applications Of Vacuum Induction Furnaces?

What Are The Applications Of A Hot Press Furnace?

What Are The Key Features Of An Atmosphere Furnace?

What Are The Key Features Of A Split Tube Furnace?

What Are The Key Features Of A Rotary Tube Furnace?

What Are The Key Features Of Multi-zone Tube Furnaces?

What Are The Advantages Of Using A Tube Furnace?

How Does A Vacuum Furnace Work?

How Does A Vacuum Induction Furnace Work?

What Are The Features Of A Hot Press Furnace?

How Does An Atmosphere Furnace Work?

How Does A Split Tube Furnace Work?

How Does A Rotary Tube Furnace Work?

How Does A Multi-zone Tube Furnace Work?

What Types Of Tube Furnaces Are Available?

What Are The Advantages Of Using A Vacuum Furnace?

What Are The Advantages Of Using A Vacuum Induction Furnace?

Why Is A Vacuum Environment Used In Hot Press Furnaces?

What Are The Advantages Of Using An Atmosphere Furnace?

What Are The Advantages Of Using A Split Tube Furnace?

What Are The Advantages Of Using A Rotary Tube Furnace?

What Are The Advantages Of Using A Multi-zone Tube Furnace?

What Temperature Ranges Can Tube Furnaces Achieve?

What Types Of Materials Can Be Processed In A Vacuum Furnace?

What Types Of Vacuum Induction Furnaces Are Available?

What Materials Are Commonly Processed In Hot Press Furnaces?

What Types Of Gases Can Be Used In An Atmosphere Furnace?

What Temperature Can A Split Tube Furnace Reach?

What Temperature Can A Rotary Tube Furnace Reach?

What Types Of Multi-zone Tube Furnaces Are Available?

Can Tube Furnaces Operate Under Different Atmospheres?

What Is The Difference Between Hot Wall And Cold Wall Vacuum Furnaces?

Why Is Temperature Control Important In Vacuum Induction Furnaces?

What Safety Features Are Available In Advanced Atmosphere Furnaces?

Why Is The Split Design Beneficial In A Tube Furnace?

What Types Of Materials Can Be Processed In A Rotary Tube Furnace?

What Makes KINTEK Tube Furnaces Special?

Can Vacuum Furnaces Be Customized For Specific Applications?

What Materials Can Be Processed In A Vacuum Induction Furnace?

How Does The Vacuum Environment Benefit Material Processing?

4.8 / 5

Incredible precision and durability! This furnace has transformed our lab work. Worth every penny!

4.7 / 5

Fast delivery and top-notch quality. The furnace performs beyond expectations. Highly recommended!

4.9 / 5

The technological advancement in this furnace is impressive. It’s a game-changer for our research!

4.8 / 5

Solid build and excellent performance. This furnace is a reliable workhorse in our lab.

4.7 / 5

Great value for money! The furnace is efficient and easy to use. Perfect for high-pressure experiments.

4.9 / 5

Outstanding quality and precision. This furnace has exceeded all our expectations. A must-have!

4.8 / 5

The furnace arrived quickly and works flawlessly. It’s a fantastic investment for any lab.

4.7 / 5

Durable and efficient. This furnace handles high-pressure tasks with ease. Very satisfied!

4.9 / 5

The furnace’s performance is stellar. It’s made our experiments so much smoother. Love it!

4.8 / 5

Top-tier technology and build quality. This furnace is a standout in our laboratory.

4.7 / 5

Fast shipping and excellent product. The furnace is perfect for our high-pressure needs.

4.9 / 5

This furnace is a dream! It’s reliable, precise, and worth every cent. Highly recommend!

4.8 / 5

The furnace is built to last. It’s been a fantastic addition to our lab. Very happy!

4.7 / 5

Great product at a great price. The furnace works perfectly and looks sleek too.

4.9 / 5

Exceptional performance and durability. This furnace is a lab essential. Absolutely love it!

4.8 / 5

The furnace is a powerhouse! It’s made our experiments so much more efficient. Superb!

4.7 / 5

High-quality and reliable. This furnace is a great investment for any serious lab.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

Split Chamber CVD Tube Furnace with Vacuum Station - High precision 1200°C lab furnace for advanced materials research. Customizable solutions available.

Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

KINTEK's Multi-Zone CVD Tube Furnaces offer precision temperature control for advanced thin film deposition. Ideal for research and production, customizable for your lab needs.

Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

KINTEK's CVD Tube Furnace offers precision temperature control up to 1600°C, ideal for thin film deposition. Customizable for research and industrial needs.

Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

Discover KINTEK's advanced Vacuum Tube Hot Press Furnace for precise high-temperature sintering, hot pressing, and material bonding. Customizable solutions for labs.

Vertical Laboratory Quartz Tube Furnace Tubular Furnace

Precision KINTEK Vertical Tube Furnace: 1800℃ heating, PID control, customizable for labs. Ideal for CVD, crystal growth & materials testing.

1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

KINTEK's Tube Furnace with Alumina Tube: Precision heating up to 1700°C for material synthesis, CVD, and sintering. Compact, customizable, and vacuum-ready. Explore now!

Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

Ultra-Vacuum Electrode Feedthroughs for reliable UHV connections. High-sealing, customizable flange options, ideal for semiconductor & space applications.

Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

KINTEK Slide PECVD Tube Furnace: Precision thin film deposition with RF plasma, rapid thermal cycling, and customizable gas control. Ideal for semiconductors and solar cells.

Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

KINTEK's PECVD coating machine delivers precision thin films at low temperatures for LEDs, solar cells & MEMS. Customizable, high-performance solutions.

2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

2200°C Tungsten Vacuum Furnace for high-temperature materials processing. Precise control, superior vacuum, customizable solutions. Ideal for research & industrial applications.

Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

KINTEK Multi-Zone Tube Furnace: Precise 1700℃ heating with 1-10 zones for advanced material research. Customizable, vacuum-ready, and safety-certified.

9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

Achieve superior ceramic densification with KINTEK's advanced air pressure sintering furnace. High-pressure up to 9MPa, precise 2200℃ control.

Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

KINTEK Laboratory Rotary Furnace: Precision heating for calcination, drying, sintering. Customizable solutions with vacuum & controlled atmosphere. Enhance research now!

Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

KINTEK's Vacuum Pressure Sintering Furnace offers 2100℃ precision for ceramics, metals, and composites. Customizable, high-performance, and contamination-free. Get a quote now!

Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

KINTEK's RTP Rapid Heating Tube Furnace delivers precise temperature control, rapid heating up to 100°C/sec, and versatile atmosphere options for advanced lab applications.

Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

Precision Split Multi Heating Zone Rotary Tube Furnace for high-temperature material processing, featuring adjustable tilt, 360° rotation, and customizable heating zones. Ideal for labs.

2200 ℃ Graphite Vacuum Heat Treat Furnace

2200℃ Graphite Vacuum Furnace for high-temperature sintering. Precise PID control, 6*10⁻³Pa vacuum, durable graphite heating. Ideal for research & production.

1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

Discover KINTEK's 1200℃ Split Tube Furnace with quartz tube for precise high-temperature lab applications. Customizable, durable, and efficient. Get yours now!

High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

KF ultra-high vacuum observation window with high borosilicate glass for clear viewing in demanding 10^-9 Torr environments. Durable 304 stainless steel flange.

Related Articles

Why Your Tube Furnace Is Failing Your Experiments (And It’s Not the Temperature)

Discover the hidden reason your high-temperature experiments fail. It's not your process; it's a material mismatch inside your furnace. Learn how to fix it.

The Unseen Architect: How Vacuum Furnaces Forge the Future of Composites

Discover how vacuum pressing transcends mechanical force, creating a controlled environment to eliminate defects and unlock the full potential of advanced composites.

Why Your Crystal Growth Experiments Are Failing: The Hidden Culprit in Your Tube Furnace

Struggling with inconsistent CVT results? Discover why your tube furnace's temperature gradient, not your chemistry, is the likely culprit and how to fix it.

The Geometry of Progress: Why the 70mm Tube Furnace is a Laboratory Cornerstone

A 70mm tube furnace isn't just about heat; it's a controlled environment where diameter dictates the balance between research precision and production scale.

The Geometry of Precision: Why a Tube Furnace's Design Is Its Greatest Strength

Discover how a tube furnace's compact design isn't just space-saving—it's the key to superior thermal uniformity and operational efficiency.

The Physics of Mismatched Tools: Why a Tube Furnace Isn't for Wastewater

A tube furnace is for precise material synthesis, not bulk water treatment. Understand the physics of heat capacity to choose the right environmental tech.

Beyond Mere Heat: The Synthesis Power of Pressure in a Vacuum Furnace

Discover why adding mechanical pressure to a vacuum furnace transforms it from a simple heater into an advanced material synthesis tool for creating dense materials.

The Geometry of Control: How Tube Furnaces Master Atmosphere and Temperature

Discover how the simple cylindrical design of a tube furnace provides unparalleled control over atmosphere and heat, making it essential for advanced materials science.

Your Furnace Isn't Just a Heater: Why 'Good Enough' Equipment Is Sabotaging Your Advanced Materials Research

Struggling with inconsistent results from your tube furnace? Discover why standard equipment fails and how a modular, customizable approach is key to success.

The Controlled Universe: Mastering Matter Inside a 70mm Tube Furnace

Explore how the tube furnace's precise control of temperature and atmosphere is fundamental to innovation in materials science, chemistry, and nanotech.

The Psychology of Failure: Why Your Alumina Tube Furnace Cracks

Learn why furnace tube failure is often a psychological error, not a material defect. Master maintenance to prevent thermal shock and protect your research.

Beyond the Spec Sheet: The Operational Realities of Corundum Tube Furnaces

Corundum tubes offer high-temp stability but hide operational risks. Understanding thermal shock, cost, and opacity is key to preventing failure.