At its core, the heating zone configuration in a vertical tube furnace is the single most important factor determining its performance, flexibility, and cost. Whether a furnace has a single heating zone or multiple zones directly dictates its ability to create a uniform temperature environment or a precisely controlled temperature gradient, which is critical for the success of specific material processing applications.

The choice between a single-zone and a multi-zone furnace is not merely about achieving a set temperature. It is about controlling the thermal profile along the length of the process tube to achieve either perfect uniformity for consistency or a specific gradient for advanced processes.

The Role of the Heating Zone: Uniformity vs. Gradient

A vertical tube furnace's primary job is to deliver controlled heat. The heating zone configuration is the mechanism that defines how that heat is delivered across the physical space of the process tube.

What Defines the Heating Zone?

The heating zone is the segment of the furnace tube surrounded by heating elements. In a single-zone furnace, one controller manages all elements. In a multi-zone furnace, the tube is surrounded by several independent sets of elements, each managed by its own controller.

The Goal of Temperature Uniformity

For many applications like annealing, sintering, or growing uniform thin films, process consistency is paramount. This requires an isothermal zone—a length of the tube where the temperature is stable and uniform.

Due to natural heat loss at the open ends of the tube, a single-zone furnace only achieves a relatively short isothermal zone in its very center.

The Power of Thermal Gradients

Conversely, some advanced processes like chemical vapor transport (CVT) or certain types of crystal growth depend on a thermal gradient, where the temperature changes predictably from one end of the zone to the other. This controlled variation drives material transport or specific phase changes.

Single-Zone vs. Multi-Zone Furnaces

The decision to use a single or multi-zone furnace directly impacts the types of processes you can run effectively.

Single-Zone: Simplicity and Cost-Effectiveness

A single-zone furnace is the simplest configuration. It is well-suited for basic heating applications, experiments where the sample is small and can be placed in the center, or when absolute temperature uniformity is not the highest priority. It is a cost-effective and easy-to-operate solution.

Multi-Zone: Precision and an Extended Uniform Zone

A three-zone furnace is a common multi-zone configuration. It features a large central zone flanked by two smaller end zones.

By setting the end zones to a slightly higher temperature, you can actively compensate for the heat that would normally be lost to the environment. This significantly lengthens the isothermal zone, enabling uniform processing of larger samples or batches.

Multi-Zone for Custom Profiles

The true power of a multi-zone furnace lies in its flexibility. By programming each zone to a different setpoint, you can create precise, stable, and repeatable thermal gradients along the tube. This capability is impossible with a single-zone furnace and is essential for many advanced research applications.

Understanding the Trade-offs

Choosing the right configuration requires balancing process needs with practical constraints.

Cost vs. Performance

A multi-zone furnace is more expensive than a single-zone model due to its additional controllers, thermocouples, and more complex power electronics. You must determine if the need for a longer uniform zone or gradient control justifies the increased investment.

Operational Complexity

While modern controllers simplify the process, programming a multi-zone furnace to achieve a specific profile requires a greater understanding of the system's thermal dynamics. A single-zone furnace offers "set-it-and-forget-it" simplicity that may be preferable for routine tasks.

The Impact of Vertical Orientation

In a vertical furnace, gravity ensures samples remain centered and promotes uniform convective heat flow. This inherent advantage is amplified by a multi-zone configuration, which perfects the thermal environment around the sample.

Choosing the Right Configuration for Your Process

Your specific application is the ultimate guide to selecting the right heating zone setup.

- If your primary focus is general-purpose heating or simple thermal treatment: A single-zone furnace offers the best balance of cost and performance for smaller samples.

- If your primary focus is achieving maximum temperature uniformity over a large area (e.g., batch annealing, high-quality film growth): A three-zone or multi-zone furnace is essential to compensate for end-zone heat loss.

- If your primary focus is advanced research requiring specific thermal gradients (e.g., vapor transport, directed crystal growth): A multi-zone furnace is the only option that provides the necessary programmable control.

Ultimately, understanding your process's thermal requirements empowers you to select a furnace that is a tool for discovery, not a limitation.

Summary Table:

| Configuration | Key Features | Best For |

|---|---|---|

| Single-Zone | Simple, cost-effective, short isothermal zone | Basic heating, small samples, routine tasks |

| Multi-Zone | Precise gradients, extended uniform zone, programmable | Advanced research, large samples, gradient-dependent processes |

Ready to elevate your material processing with the right furnace? KINTEK specializes in high-temperature solutions tailored to your needs. Leveraging exceptional R&D and in-house manufacturing, we offer advanced vertical tube furnaces with customizable heating zones—whether single or multi-zone—to ensure precise temperature control for applications like annealing, sintering, and crystal growth. Our deep customization capability means we can design a furnace that perfectly matches your unique experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and drive your research forward!

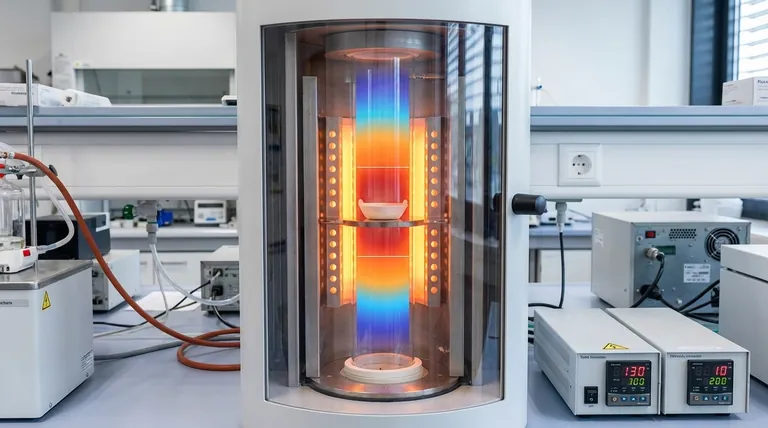

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety