The primary drawbacks of corundum tube furnaces are their significant financial cost, their inherent opacity which prevents direct sample observation, and their susceptibility to cracking from thermal shock. These factors introduce material, observational, and operational constraints that must be carefully managed.

While corundum (high-purity alumina) offers exceptional performance at extreme temperatures, its physical properties introduce significant operational constraints. Understanding these limitations is critical for preventing equipment failure and ensuring experimental success.

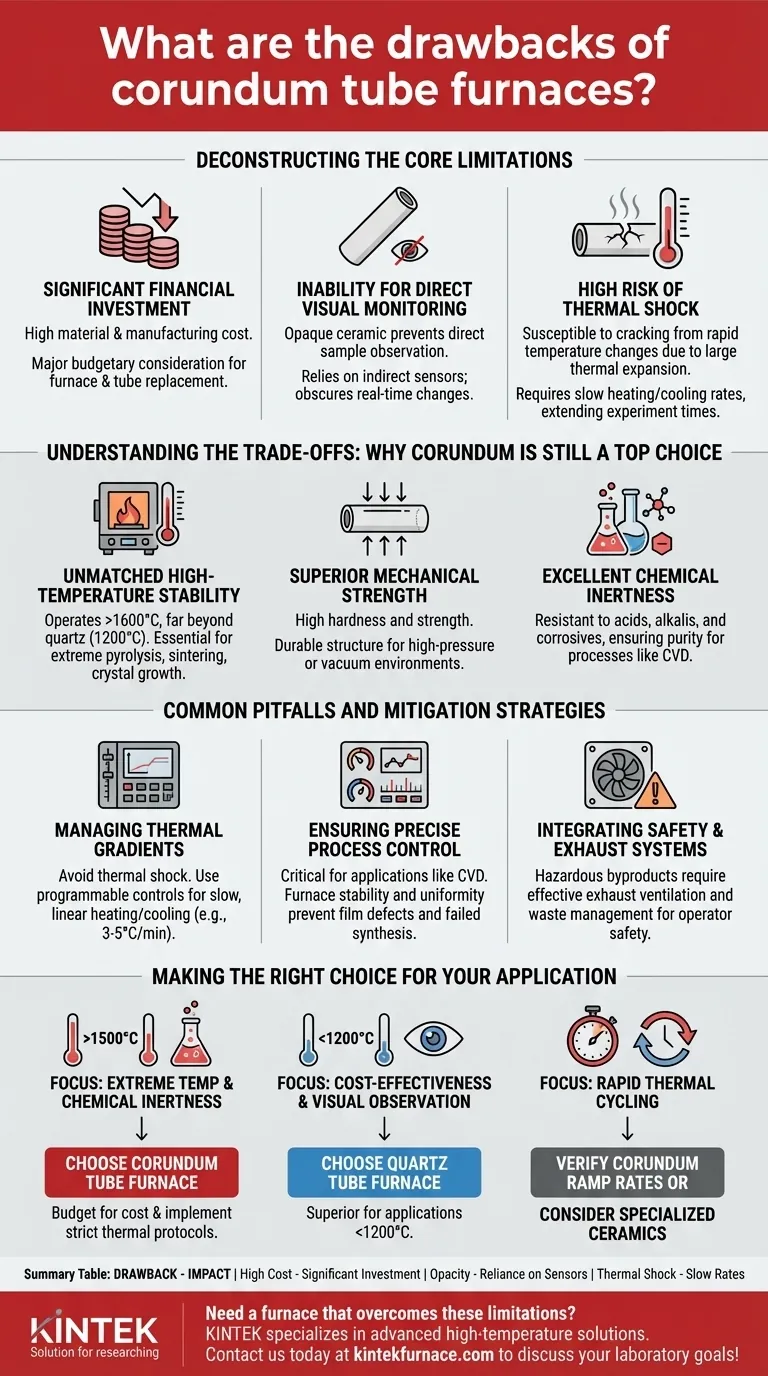

Deconstructing the Core Limitations

To properly evaluate a corundum tube furnace, you must understand its three main disadvantages in detail. Each presents a distinct challenge that impacts budget, experimental design, and daily operation.

Significant Financial Investment

Corundum tubes are manufactured from high-purity aluminum oxide, a material that is expensive to source and process. The manufacturing process itself, which requires extremely high temperatures and precise controls, adds to the high final cost.

This makes the initial purchase of the furnace, as well as the replacement of the consumable tube, a major budgetary consideration compared to alternatives like quartz.

Inability for Direct Visual Monitoring

Corundum is an opaque ceramic. Unlike a transparent quartz tube, you cannot visually monitor the sample during a thermal process.

This lack of direct observation forces a reliance on indirect methods, such as thermocouples and other sensors, to infer the state of the material inside. This can complicate troubleshooting and the identification of physical changes like melting or color shifts in real-time.

High Risk of Thermal Shock

Corundum has a relatively large thermal expansion coefficient. This means it expands and contracts significantly with temperature changes.

If heated or cooled too rapidly, uneven temperature distribution across the tube creates internal stress. This stress can easily exceed the material's structural limits, causing it to crack or even shatter. This necessitates slow, carefully programmed heating and cooling rates, which can extend experiment times.

Understanding the Trade-offs: Why Corundum Is Still a Top Choice

Despite these clear drawbacks, corundum tube furnaces are indispensable in many advanced applications. The trade-offs are accepted because no other common material can match its performance in key areas.

Unmatched High-Temperature Stability

Corundum tubes can operate continuously at temperatures exceeding 1600°C, and some grades go even higher. This is far beyond the operational limit of quartz, which typically softens around 1200°C. For high-temperature pyrolysis, sintering, or crystal growth, corundum is often the only choice.

Superior Mechanical Strength

The material possesses high mechanical strength and hardness. This allows it to withstand high-pressure or vacuum environments and provides a durable, rigid structure for complex experimental setups.

Excellent Chemical Inertness

Corundum exhibits exceptional resistance to chemical attack from a wide range of acids, alkalis, and other corrosive substances, even at high temperatures. This ensures the purity of the sample and the longevity of the tube in harsh chemical environments, such as those used in Chemical Vapor Deposition (CVD).

Common Pitfalls and Mitigation Strategies

Successfully using a corundum tube furnace means actively mitigating its inherent risks. Ignoring these operational requirements is a common cause of costly equipment failure.

Managing Thermal Gradients

The single most critical protocol is to avoid thermal shock. Always use a programmable controller to enforce slow, linear heating and cooling rates. A typical safe rate is often between 3-5°C per minute, but you must consult your specific tube's documentation.

Ensuring Precise Process Control

Applications like CVD demand extremely precise control over temperature, pressure, and gas flow. The furnace is the heart of this system. Its stability and uniformity are paramount, as deviations can lead to film defects or failed synthesis. The furnace's performance must match the strict requirements of your process.

Integrating Safety and Exhaust Systems

Many processes run in tube furnaces, particularly CVD, can generate hazardous byproducts or involve toxic and reactive precursor gases. The furnace setup must be part of a larger, well-designed system that includes effective exhaust ventilation and waste management to ensure operator safety and environmental compliance.

Making the Right Choice for Your Application

Your decision must be guided by the specific demands of your research or process.

- If your primary focus is extreme temperature processing (>1500°C) or chemical inertness: Corundum is the correct, and often only, choice, but you must budget for the cost and implement strict operational protocols for heating and cooling.

- If your primary focus is cost-effectiveness and visual observation is critical: A quartz tube furnace is a superior alternative for any application that remains below approximately 1200°C.

- If your primary focus is rapid thermal cycling: You must verify that corundum can handle your required ramp rates or investigate specialized, more expensive ceramics engineered for thermal shock resistance.

By weighing these factors against your specific experimental goals, you can confidently select the right material and avoid costly failures.

Summary Table:

| Drawback | Description | Impact |

|---|---|---|

| High Cost | Expensive material and manufacturing | Significant financial investment |

| Opacity | Cannot visually monitor samples | Reliance on indirect sensors |

| Thermal Shock | Susceptible to cracking from rapid temperature changes | Requires slow heating/cooling rates |

Need a furnace that overcomes these limitations? KINTEK specializes in advanced high-temperature solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems with deep customization capabilities. Whether you're dealing with extreme temperatures, chemical inertness, or rapid cycling, our expertise ensures reliable performance and enhanced efficiency. Contact us today to discuss how we can support your laboratory goals!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation