At their core, tubular furnaces are high-temperature ovens designed for processing materials with exceptional precision. Their primary applications revolve around heat treatment processes like annealing and sintering, chemical synthesis and purification, and materials testing, particularly when a controlled atmosphere is required. They are indispensable tools in research, development, and specialized small-batch production across numerous scientific and industrial fields.

The true value of a tubular furnace isn't just its ability to get hot, but its capacity to create a highly uniform and chemically controlled environment. This makes it the ideal instrument for processes where precision and repeatability are more critical than sheer volume.

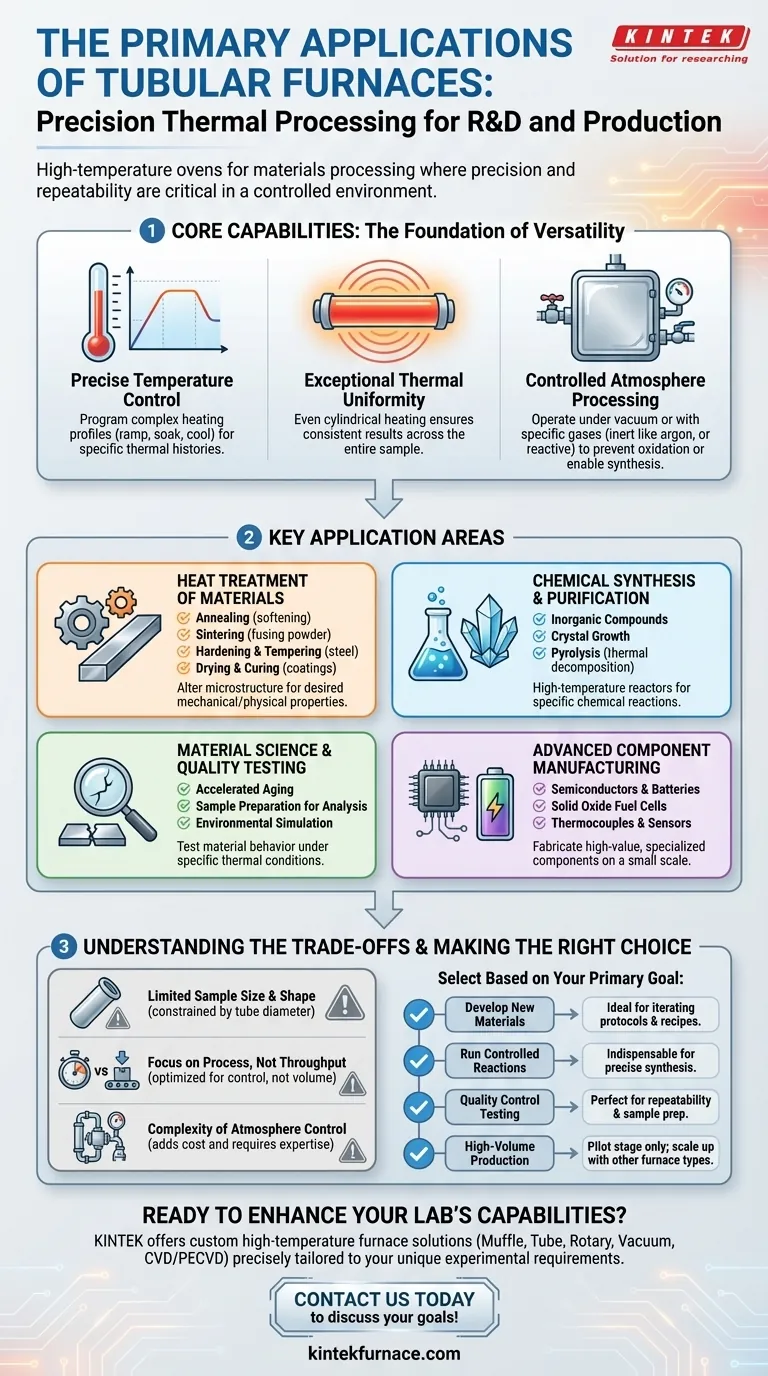

Core Capabilities: The Foundation of Their Versatility

To understand the applications of a tubular furnace, you must first understand its three fundamental capabilities. These features are what make it the superior choice for a specific class of thermal processing tasks.

Precise Temperature Control

Tubular furnaces provide exceptional control over the entire thermal cycle. They can be programmed to follow very specific heating profiles, including controlled ramp-up rates, extended soaking periods at a set temperature, and managed cooling phases.

This level of control is critical for processes where the material's final properties are highly dependent on its thermal history.

Exceptional Thermal Uniformity

The cylindrical design of the heating chamber ensures that the sample is heated evenly from all sides. This thermal uniformity is vital for achieving consistent results across the entire sample.

Without it, different parts of a material could end up with different microstructures and properties, rendering the process unreliable for sensitive applications like semiconductor or ceramic manufacturing.

Controlled Atmosphere Processing

This is arguably the most important feature for many advanced applications. The tube can be sealed and evacuated to create a vacuum, or it can be purged and filled with a specific gas or gas mixture.

Using an inert gas like argon prevents unwanted oxidation of metals at high temperatures. Using a reactive gas can be a deliberate part of a chemical synthesis process, such as in certain types of chemical vapor deposition (CVD).

Key Application Areas

The combination of precise temperature, uniformity, and atmosphere control makes tubular furnaces essential in four primary domains.

Heat Treatment of Materials

This is the most common category of use. These processes are designed to alter the microstructure of a material to achieve desired mechanical or physical properties.

Key examples include:

- Annealing: Softening metals or glass to improve ductility and reduce internal stresses.

- Sintering: Fusing powders together below their melting point to create a solid object, common in ceramics and powder metallurgy.

- Hardening & Tempering: A two-step process to increase the hardness and toughness of steel.

- Drying & Curing: Removing moisture or solvents from materials or curing coatings and polymers.

Chemical Synthesis and Purification

Tubular furnaces act as high-temperature chemical reactors, providing the energy and controlled environment needed for specific reactions to occur.

This includes the synthesis and purification of inorganic compounds, crystal growth, and processes like pyrolysis, where organic material (like biomass) is thermally decomposed in the absence of oxygen.

Material Science and Quality Testing

In research and quality control, these furnaces are used to test material behavior under specific thermal conditions.

This can involve accelerated aging tests to see how a material withstands high temperatures over time, preparing samples for analysis with tools like spectrometers, or testing the performance of aerospace or energy components in simulated environments.

Advanced Component Manufacturing

While not suited for mass production, tubular furnaces are critical for fabricating high-value, specialized components on a smaller scale.

Prominent industrial uses include the production of materials for semiconductors and batteries, the creation of solid oxide fuel cells, and the manufacturing of thermocouples and other specialized sensors.

Understanding the Trade-offs

Despite their versatility, tubular furnaces are a specialized tool with clear limitations. Understanding these is key to using them effectively.

Limited Sample Size and Shape

The defining feature of the furnace—its tube—is also its primary constraint. It is inherently limited to processing samples that can fit within the tube's diameter. This makes it unsuitable for large or irregularly shaped objects.

Focus on Process, Not Throughput

These furnaces are optimized for process control, not high-volume output. Their strength lies in executing a complex thermal cycle perfectly on a small batch, not in processing large quantities of material quickly.

Complexity of Atmosphere Control

While powerful, creating and maintaining a specific atmosphere adds complexity and cost. It requires vacuum pumps, gas lines, flow controllers, and safety protocols, especially when working with flammable or reactive gases.

Making the Right Choice for Your Goal

When deciding if a tubular furnace fits your needs, consider your ultimate objective.

- If your primary focus is developing new materials: A tubular furnace is ideal for iterating on heat treatment protocols and synthesis recipes on a small, controlled scale.

- If your primary focus is running controlled chemical reactions: The precise management of temperature and atmosphere makes it an indispensable tool for synthesis, purification, and pyrolysis.

- If your primary focus is quality control testing: The furnace's precision and repeatability are perfect for simulating environmental stress or preparing consistent samples for analysis.

- If your primary focus is high-volume production: A tubular furnace is likely only suitable for a pilot stage; you will need to investigate larger batch or continuous furnaces for scaling up.

Ultimately, a tubular furnace excels wherever precise control over a material's thermal and chemical environment is more critical than the size or quantity being processed.

Summary Table:

| Application Area | Key Uses |

|---|---|

| Heat Treatment | Annealing, sintering, hardening, tempering, drying, curing |

| Chemical Synthesis | Synthesis, purification, pyrolysis, crystal growth |

| Materials Testing | Accelerated aging, sample preparation, environmental simulation |

| Manufacturing | Semiconductor materials, batteries, fuel cells, sensors |

Ready to enhance your lab's capabilities with a custom tubular furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, whether for research, development, or specialized production. Contact us today to discuss how we can support your thermal processing goals!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the material requirements for furnace tubes? Optimize Performance and Safety in High-Temperature Labs

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision