At their core, the choice between a tube furnace and a box furnace comes down to process geometry. A tube furnace is designed for processing materials, often in a controlled atmosphere, as they pass through a narrow cylindrical chamber. In contrast, a box furnace is a larger, sealed chamber designed for the general-purpose heat treatment of static batches of material.

The decision is not about which furnace is inherently superior, but which architecture—a continuous flow-through tube or a static batch chamber—aligns with your specific material, sample size, and atmosphere requirements.

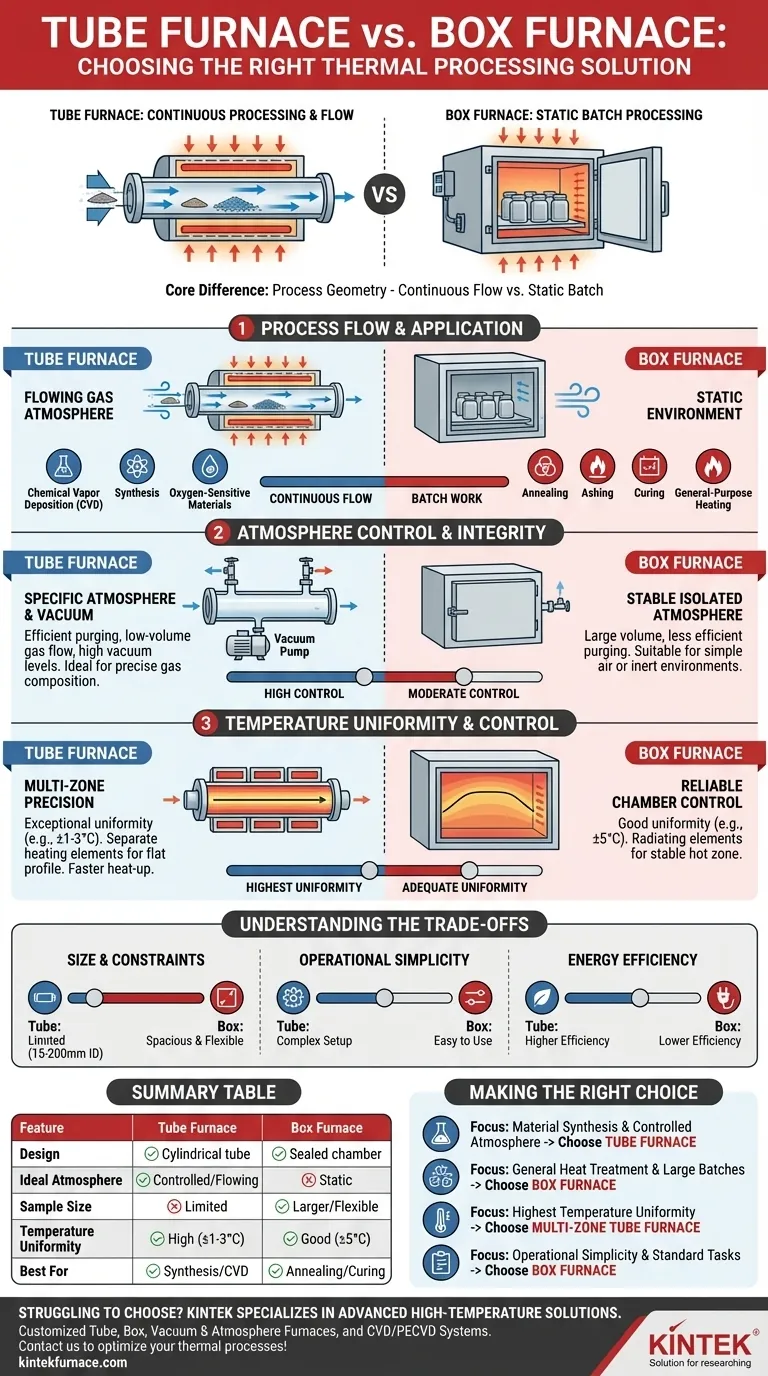

The Fundamental Design Difference: Process Flow

The most significant distinction between these furnaces is how they hold and process the material being heated. This design choice dictates their ideal applications.

Tube Furnaces: Continuous Processing and Flow

A tube furnace is built around a long cylindrical tube, which serves as the heating chamber. Materials are either passed through this tube continuously or placed within it for processing.

This design is exceptionally well-suited for applications that require a flowing gas atmosphere. The narrow geometry makes it easy to purge the air and introduce inert gases, reactive gases, or create a vacuum, ensuring the atmosphere interacts consistently with the material along the length of the tube.

Box Furnaces: Static Batch Processing

A box furnace, also known as a muffle furnace, features a large, front-loading chamber. You place the materials to be heated inside, close the door, and run the heating cycle.

This architecture is ideal for batch work. Its spacious interior can accommodate larger parts, multiple smaller samples, or crucibles that would not fit inside a narrow tube. The environment is static and contained, making it a reliable workhorse for general-purpose applications like annealing, ashing, and curing.

Comparing Atmosphere Control and Integrity

Your ability to control the environment around your sample is a critical factor and a major point of difference between the two furnace types.

Why Tube Furnaces Excel with Specific Atmospheres

Tube furnaces offer superior flexibility for processes that demand a specific atmosphere. Their geometry allows for efficient purging and the maintenance of a consistent, low-volume gas flow from one end to the other.

This makes them the standard choice for working with oxygen-sensitive materials, performing chemical vapor deposition (CVD), or other syntheses where the gas composition is a critical process variable. Vacuum-sealed models can achieve very high vacuum levels for specialized applications.

The Stable Environment of a Box Furnace

A box furnace provides a stable, isolated atmosphere. Once the chamber is sealed, the internal environment is largely cut off from the outside. While many models include gas ports to introduce an inert atmosphere, the large volume makes it less efficient to purge and control than a tube furnace.

For general heat treatment where the goal is simply to heat a material in air or a static inert environment, a box furnace is perfectly adequate and much simpler to operate.

Temperature Uniformity and Control

While both furnace types offer high precision, their approach to temperature uniformity differs based on their design.

The Precision of Multi-Zone Tube Furnaces

Tube furnaces, especially three-zone models, offer the best temperature uniformity available. By having separate heating elements and controllers for the center and end zones, they can create an exceptionally flat temperature profile along the central length of the tube.

This level of control is vital for crystal growth, annealing long components, or any process where temperature variation across the sample must be minimized. Tube furnaces also tend to have faster heat-up times due to their lower thermal mass.

The Reliability of Box Furnace Chambers

Modern box furnaces provide excellent temperature control, often within ±5°C or better. The heat radiates from elements surrounding the chamber, creating a stable and reasonably uniform hot zone.

While they may not match the precise uniformity of a multi-zone tube furnace, their performance is more than sufficient for the vast majority of industrial and laboratory batch processes. More advanced atmosphere box furnaces can achieve tighter control (±1–3°C) with gas circulation systems.

Understanding the Trade-offs

Choosing the right furnace requires acknowledging the inherent limitations and advantages of each design.

Size and Sample Constraints

The most obvious trade-off is sample size. Tube furnaces are restrictive by nature, limited by the inner diameter of the processing tube (typically 15 mm to 200 mm). Box furnaces offer far more space and flexibility for bulky items or large numbers of samples.

Operational Simplicity vs. Process Flexibility

Box furnaces are champions of simplicity. They are easy to load, operate, and maintain, making them ideal for multi-user environments or straightforward heating tasks.

Tube furnaces offer greater process flexibility, particularly with atmosphere control, but can be more complex to set up. Sealing the tube ends, managing gas flow, and programming multiple zones requires more technical attention.

Energy Efficiency

Due to their smaller heated volume and more targeted design, tube furnaces are generally more energy-efficient and have faster heat-up and cool-down cycles compared to a large box furnace of similar temperature rating.

Making the Right Choice for Your Application

Selecting the correct furnace is an exercise in matching the tool to the task. Base your decision on your primary process requirements.

- If your primary focus is material synthesis in a controlled, flowing atmosphere: Choose a tube furnace for its superior gas handling capabilities.

- If your primary focus is general heat treatment of larger batches or varied sample sizes: Choose a box furnace for its spacious chamber and operational simplicity.

- If your primary focus is achieving the highest possible temperature uniformity for a specific sample: Choose a multi-zone tube furnace for its precise temperature profiling.

- If your primary focus is operational simplicity for standard annealing, ashing, or curing: Choose a box furnace as the reliable and straightforward workhorse.

Understanding these core architectural differences empowers you to select the furnace that is not just a tool, but a precise solution to your thermal processing challenge.

Summary Table:

| Feature | Tube Furnace | Box Furnace |

|---|---|---|

| Design | Cylindrical tube for continuous flow | Sealed chamber for static batch processing |

| Ideal Atmosphere | Controlled, flowing gases (e.g., inert, reactive) | Static environments (e.g., air, inert) |

| Sample Size | Limited by tube diameter (15-200 mm) | Larger, flexible for bulky items or multiple samples |

| Temperature Uniformity | High with multi-zone models (e.g., ±1-3°C) | Good for most applications (e.g., ±5°C) |

| Best For | Material synthesis, CVD, oxygen-sensitive processes | Annealing, ashing, curing, general-purpose heating |

Struggling to choose the right furnace for your lab? KINTEK specializes in advanced high-temperature solutions tailored to your needs. With exceptional R&D and in-house manufacturing, we offer a diverse product line including Tube Furnaces, Box Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, enhancing efficiency and results. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability