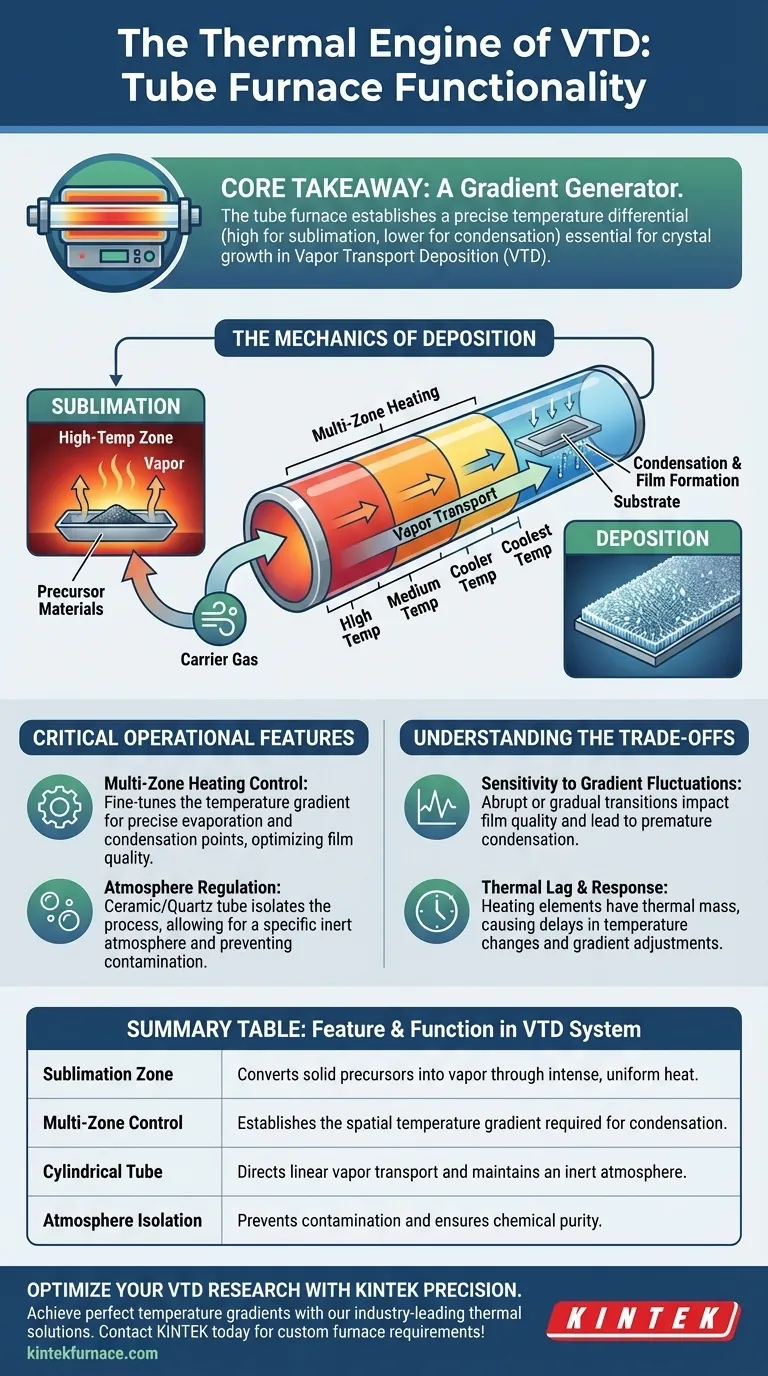

The tube furnace serves as the thermal engine of a Vapor Transport Deposition (VTD) system. Its primary role is to create a controlled environment that converts solid precursor materials into vapor through sublimation. By maintaining distinct heating zones, it drives the movement of this vapor toward a substrate for eventual condensation and film formation.

Core Takeaway The tube furnace is not merely a heating element; it is a gradient generator. Its critical function is establishing a precise temperature differential—high heat to vaporize the source and lower heat to condense it onto a substrate—which is the fundamental mechanism enabling crystal growth in VTD.

The Mechanics of Deposition

Sublimation of Precursors

The first stage of the VTD process occurs in the furnace's high-temperature zones. Here, the furnace applies intense, uniform heat to solid precursor materials.

This thermal energy causes the materials to sublimate, transitioning directly from a solid state into a vapor. Without this capability to reach and sustain specific volatilization temperatures, the deposition process cannot begin.

Creating the Spatial Temperature Gradient

The most critical technical contribution of the tube furnace is the creation of a spatial temperature gradient. The system does not maintain a single uniform temperature across the entire tube length.

Instead, the furnace is configured to keep the source material at a high temperature while the substrate is positioned in a relatively cooler zone. This differential is essential for managing the rate at which the material vaporizes and subsequently deposits.

Facilitating Vapor Transport

While the carrier gas provides the motive force, the physical design of the furnace tube directs the flow. The cylindrical geometry ensures that the vapor moves linearly from the hot generation zone to the cooler deposition zone.

The furnace maintains the thermal conditions necessary to keep the vapor suspended in the carrier gas until it reaches the target substrate.

Critical Operational Features

Multi-Zone Heating Control

To achieve the necessary gradient, VTD tube furnaces often utilize multi-zone heating configurations. This allows operators to set independent temperature profiles for different sections of the tube.

By fine-tuning these zones, you can precisely control where evaporation occurs and exactly where condensation begins, optimizing the quality of film crystallization.

Atmosphere Regulation

The ceramic or quartz tube within the furnace acts as an isolation chamber. It allows the process to occur under a specific atmosphere, usually an inert carrier gas, while excluding external contaminants.

This isolation is vital for material synthesis, ensuring that the chemical composition of the deposited film remains pure and unaffected by the ambient environment.

Understanding the Trade-offs

Sensitivity to Gradient Fluctuations

The effectiveness of a VTD system is heavily dependent on the stability of the temperature gradient. If the transition from hot to cold is too abrupt or too gradual, the film quality will suffer.

Inaccurate thermal profiles can lead to premature condensation on the tube walls rather than the substrate, resulting in wasted material and poor deposition rates.

Thermal Lag and Response

Electric tube furnaces rely on heating elements and insulation that have thermal mass. This can result in a delay when changing temperature settings.

Operators must account for this thermal lag when designing temperature profiles, as rapid changes in the gradient are often difficult to achieve instantaneously.

Making the Right Choice for Your Goal

To select the correct furnace configuration for your VTD application, consider your specific crystallization requirements:

- If your primary focus is precise film thickness: Prioritize a furnace with advanced multi-zone controllers to fine-tune the temperature gradient and condensation rate.

- If your primary focus is material purity: Ensure the furnace tube material (e.g., high-purity ceramic or quartz) is chemically compatible with your precursors to prevent cross-contamination.

- If your primary focus is process repeatability: Look for high-quality insulation and digital instrumentation that minimizes thermal fluctuations between runs.

The success of your Vapor Transport Deposition relies entirely on the furnace’s ability to maintain a stable, repeatable, and precise thermal profile.

Summary Table:

| Feature | Function in VTD System |

|---|---|

| Sublimation Zone | Converts solid precursors into vapor through intense, uniform heat. |

| Multi-Zone Control | Establishes the spatial temperature gradient required for condensation. |

| Cylindrical Tube | Directs linear vapor transport and maintains an inert atmosphere. |

| Atmosphere Isolation | Prevents contamination and ensures chemical purity of the deposited film. |

Optimize Your VTD Research with KINTEK Precision

Achieving the perfect temperature gradient is the difference between a failed run and a high-quality crystalline film. KINTEK provides the industry-leading thermal solutions required for successful Vapor Transport Deposition.

Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need multi-zone heating for precise gradient control or specialized quartz tube configurations, our lab high-temp furnaces are fully customizable to meet your unique material synthesis needs.

Ready to elevate your material deposition process? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Dachang Liu. Vapor Transport Deposition Technology for Perovskite Films. DOI: 10.1002/admi.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What role does a high-temperature tube furnace play in biomass carbonization? Unlock Superior Biochar Structures

- What is a 70mm tube furnace and what is its primary use? Unlock Precision in Material Processing

- How does a tube furnace ensure uniform temperature distribution? Discover Key Mechanisms for Precise Heating

- Why is a high-vacuum sealed quartz tube required for the heat treatment of Te1S7/C composites? Ensure Purity & Loading

- What is the significance of using perforated tapered silicone stoppers to seal quartz tube reactors? Achieve Precision.

- What physical conditions does a high-temperature tube furnace provide? Optimize Lignin Carbonization Success

- Why is environment control in a tube furnace critical for NASICON? Optimize Ionic Conductivity and Density

- What environmental conditions does a tube furnace provide for CFeS aerogels? Master Carbonization & Inert Protection