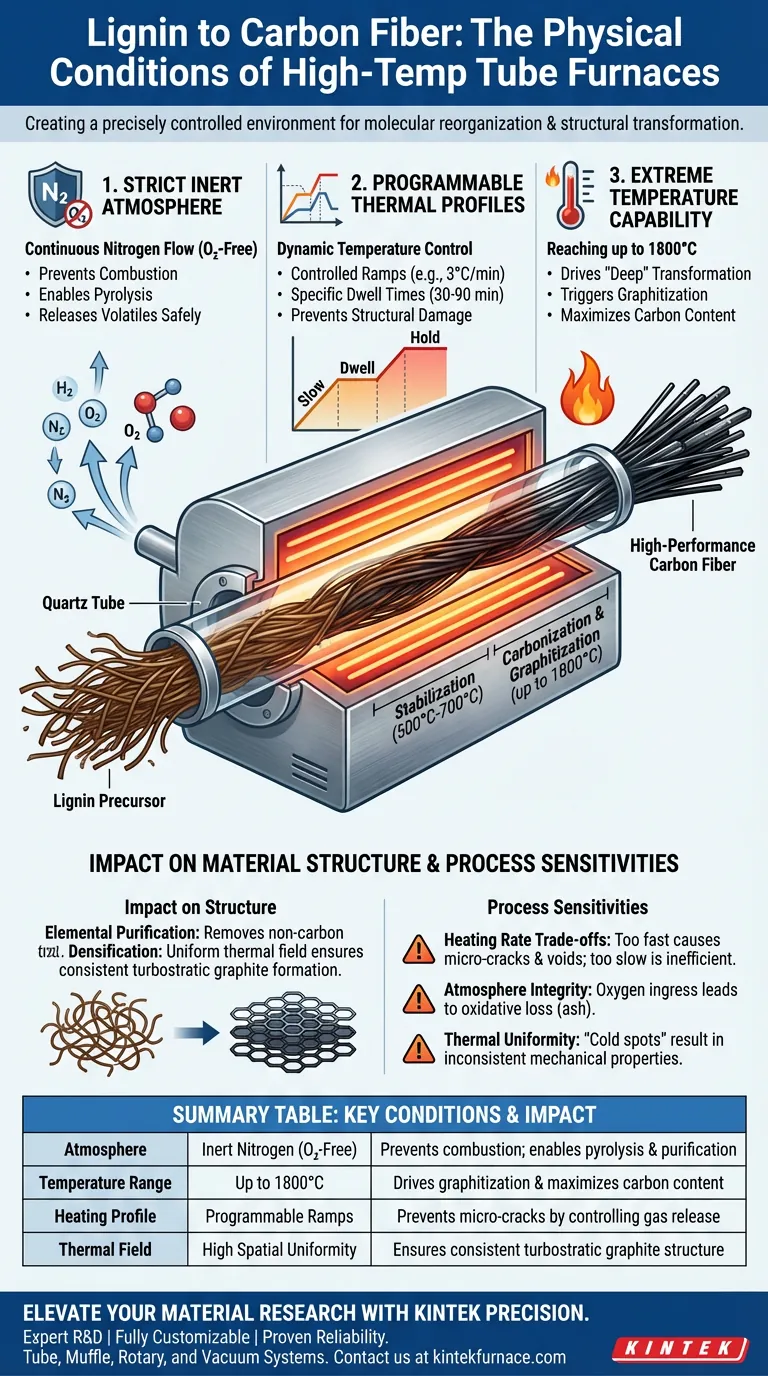

A high-temperature tube furnace creates a precisely controlled reaction environment essential for converting lignin into high-performance carbon fiber. Specifically, it provides a programmable inert nitrogen atmosphere and a uniform thermal field capable of reaching temperatures up to 1800°C. These conditions facilitate the removal of non-carbon elements without combustion, driving the structural transformation from raw biomass to crystalline graphite.

Core Insight The furnace is not merely a heating device; it is a mechanism for molecular reorganization. Success depends on the strict synchronization of an oxygen-free environment with a uniform thermal field, which directly determines the mechanical integrity and turbostratic order of the final carbon fiber.

The Critical Physical Environments

To convert lignin fibers into carbon fibers effectively, the furnace must maintain three distinct physical conditions.

Strict Inert Atmosphere

The most immediate requirement is the complete exclusion of oxygen. The furnace operates under a continuous flow of inert gas, typically nitrogen.

This atmosphere prevents the lignin fibers from combusting (burning away) as temperatures rise. Instead of oxidizing, the material undergoes pyrolysis, where volatile components can be safely released.

Programmable Thermal Profiles

Carbonization is not achieved by static heating; it requires dynamic temperature control. The furnace provides complex, multi-stage heating curves.

For lignin specifically, this often involves controlled ramping rates (e.g., 3°C/min) and specific dwell times (30 to 90 minutes). This slow, deliberate heating prevents structural damage caused by the rapid release of gases.

Extreme Temperature Capability

While initial carbonization and stabilization may occur between 500°C and 700°C, high-performance applications require much higher limits.

The furnace must be capable of reaching up to 1800°C. It is at these extreme temperatures that the "deep" transformation occurs, triggering graphitization and maximizing the carbon content of the fiber.

The Impact on Material Structure

The physical conditions inside the furnace directly dictate the chemical evolution of the lignin precursor.

Elemental Purification

The high heat, combined with the nitrogen sweep, forces the removal of non-carbon atoms.

Elements such as nitrogen, oxygen, and hydrogen are volatilized and expelled from the fiber. This process enriches the carbon content, transitioning the material from a complex organic polymer to a pure carbon structure.

Structural Densification and Ordering

The uniformity of the thermal field is the defining factor for quality.

A uniform heat distribution ensures that the turbostratic graphite structure forms evenly throughout the fiber. This directly correlates to the mechanical integrity and density of the final product.

Understanding Process Sensitivities

While the furnace provides the necessary conditions, slight deviations can lead to critical failures in the material.

Heating Rate Trade-offs

The heating rate is a balance between efficiency and quality.

If the heating rate is too aggressive (too fast), the rapid off-gassing of volatiles can create micro-cracks or voids in the fiber, destroying its mechanical strength. If the rate is too slow, the process becomes energy-inefficient.

Atmosphere Integrity

The flow of nitrogen must be sufficient to sweep away volatiles but stable enough to maintain positive pressure.

Any breach in the airtight environment that allows oxygen ingress will result in oxidative loss, effectively turning your precursor material into ash rather than carbon fiber.

Thermal Uniformity Issues

If the furnace has "cold spots" or uneven heating zones, the fibers will suffer from inconsistent graphitization.

This results in a batch of fibers with variable mechanical properties, making them unsuitable for high-performance structural applications.

Making the Right Choice for Your Goal

When configuring a tube furnace for lignin carbonization, your specific objectives should dictate your parameter settings.

- If your primary focus is Maximum Mechanical Strength: Prioritize thermal field uniformity and ultra-high temperatures (up to 1800°C) to maximize graphitization and structural order.

- If your primary focus is Precursor Yield and Stability: Focus on the lower temperature range (500°C–700°C) with slower heating rates (around 3°C/min) to ensure gentle devolatilization without cracking the fiber.

Ultimately, the quality of your carbon fiber is determined not just by how hot the furnace gets, but by how precisely it controls the removal of everything that isn't carbon.

Summary Table:

| Physical Condition | Technical Requirement | Impact on Lignin Fiber |

|---|---|---|

| Atmosphere | Inert Nitrogen (Oxygen-Free) | Prevents combustion; enables pyrolysis & purification |

| Temperature Range | Up to 1800°C | Drives graphitization and maximizes carbon content |

| Heating Profile | Programmable Ramps (e.g., 3°C/min) | Prevents micro-cracks by controlling gas release |

| Thermal Field | High Spatial Uniformity | Ensures consistent turbostratic graphite structure |

Elevate Your Material Research with KINTEK Precision

Precision is the difference between high-performance carbon fiber and industrial waste. KINTEK provides world-class Tube, Muffle, Rotary, and Vacuum systems designed specifically for the rigorous demands of biomass carbonization and advanced material synthesis.

Why choose KINTEK?

- Expert R&D: Our systems are engineered for ultra-stable thermal fields and airtight atmosphere integrity.

- Fully Customizable: Tailor your heating zones, gas flow systems, and temperature limits to your unique lignin precursor needs.

- Proven Reliability: Backed by years of manufacturing excellence in high-temperature lab equipment.

Ready to achieve superior structural densification in your fibers? Contact our technical team today to find the perfect customizable furnace solution for your laboratory.

Visual Guide

References

- Qi Hua, Scott Renneckar. Functionalized Lignin Derivatives as Melt‐Spinnable Precursors for Carbon Fiber Production without Stabilization. DOI: 10.1002/adfm.202509131

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary applications of tube furnaces? Unlock Precision in High-Temperature Processing

- How does secondary pyrolysis activation in a tube furnace at 800 °C contribute to the pore structure of APC?

- What role does a high-temperature tube furnace play in converting MXene derivatives into N-TiO2@NC? Unlock Precision Synthesis

- What are the features of multi-zone tube furnaces? Unlock Precision Heating for Your Lab

- Why is a tube furnace essential for the reduction treatment of Y-NiMo/MoO2-x? Master Precision Synthesis

- How does tube material affect furnace performance? Choose the Right Material for Optimal Results

- What are the technical specifications of the two-heating-zone tube furnace? Unlock Precise Thermal Gradients

- What is the primary function of a high-temperature tube furnace in Bi-doped CaZnOS synthesis? Achieving Phase Purity