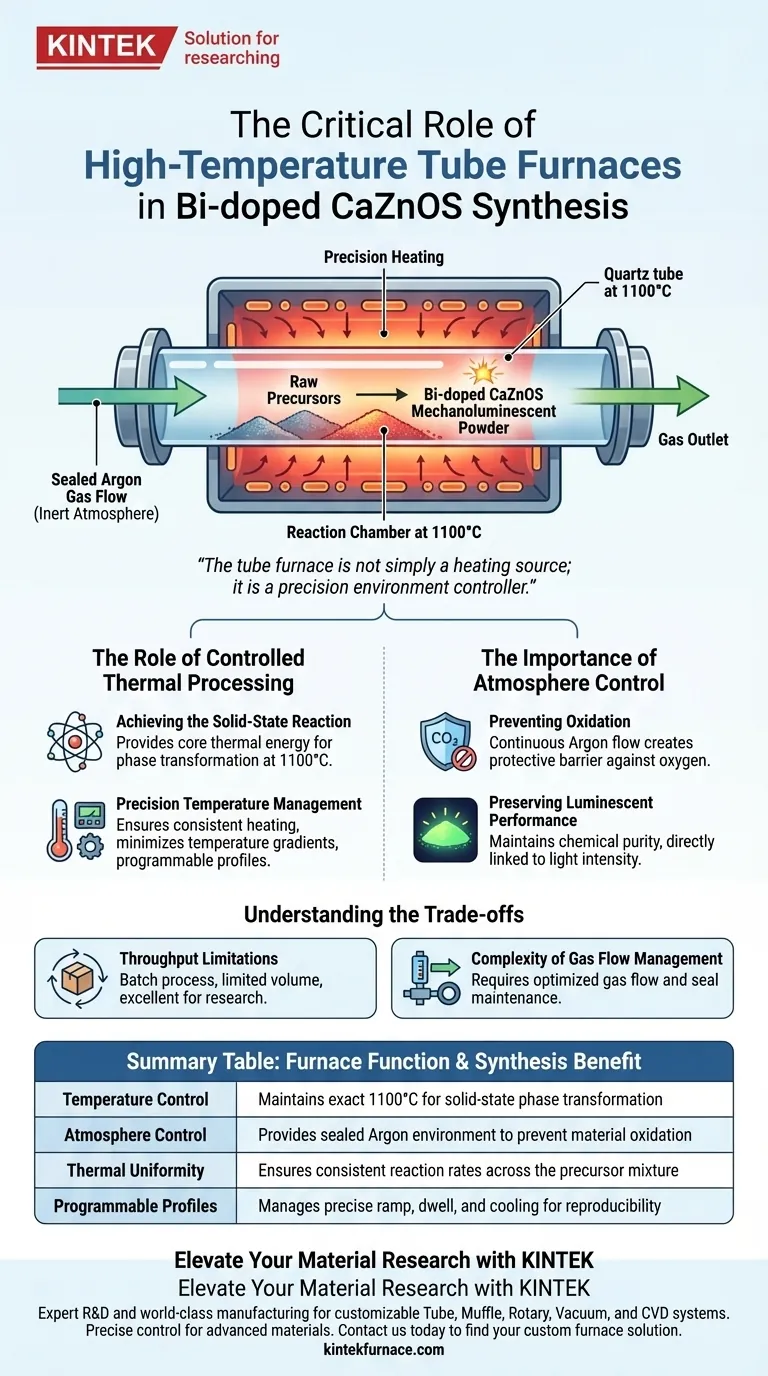

The high-temperature tube furnace serves as the critical reaction chamber for the synthesis of Bi-doped CaZnOS mechanoluminescent powders. Its primary function is to facilitate a solid-state reaction at exactly 1100°C while maintaining a sealed, inert argon atmosphere to prevent oxidation of the raw materials.

The tube furnace is not simply a heating source; it is a precision environment controller. It drives the necessary phase transformation through high heat while simultaneously shielding the chemical composition from environmental contaminants, ensuring the material retains its ability to emit light under mechanical stress.

The Role of Controlled Thermal Processing

Achieving the Solid-State Reaction

The synthesis of Bi-doped CaZnOS requires a specific type of chemical bonding that only occurs at elevated temperatures. The tube furnace provides the core thermal energy needed to reach 1100°C.

At this temperature, the raw materials undergo a solid-state reaction. This process transforms the precursor mixture into the final phosphor compound necessary for mechanoluminescence.

Precision Temperature Management

Tube furnaces are designed to deliver consistent heating across the length of the tube. This minimizes temperature gradients that could lead to uneven reaction rates within the sample.

Advanced controllers allow for programmable heating profiles. This ensures that the ramp-up to 1100°C, the dwell time, and the cooling phase are executed with high reproducibility.

The Importance of Atmosphere Control

Preventing Oxidation

A critical requirement for Bi-doped CaZnOS is the exclusion of oxygen during the heating phase. The tube furnace’s sealed chamber allows for a continuous flow of argon gas.

This inert atmosphere creates a protective barrier around the reactants. Without this protection, the high temperatures would cause immediate oxidation, altering the chemical composition of the final powder.

Preserving Luminescent Performance

The "mechanoluminescent" property—the ability to emit light when stressed—is highly sensitive to impurities.

By strictly controlling the atmosphere, the furnace ensures the accuracy of the chemical composition. This purity is directly linked to the intensity and reliability of the material's luminescent performance.

Understanding the Trade-offs

Throughput Limitations

While tube furnaces offer exceptional control over atmosphere and temperature, they are generally batch-process tools.

The physical constraints of the tube diameter limit the volume of powder that can be synthesized at one time. This makes them excellent for research and high-precision batches, but potentially bottlenecked for large-scale industrial production compared to continuous kilns.

Complexity of Gas Flow Management

Using an inert atmosphere adds a layer of operational complexity.

Users must ensure the gas flow rate is optimized—too low, and oxygen may leak in; too high, and it may disturb the powder or cool the sample surface unevenly. Maintaining the integrity of the seals at 1100°C is a constant maintenance requirement.

Making the Right Choice for Your Goal

To maximize the quality of your Bi-doped CaZnOS powders, focus on these operational priorities:

- If your primary focus is Phase Purity: Prioritize the integrity of the argon atmosphere system, ensuring zero leaks in the tube seals to prevent oxidation defects.

- If your primary focus is Reproducibility: Utilize the furnace's programmable features to standardize the ramp rates and dwell times, removing operator variability from the heating profile.

Mastering the balance between thermal precision and atmospheric control is the key to unlocking the full potential of your mechanoluminescent materials.

Summary Table:

| Feature | Function in Bi-doped CaZnOS Synthesis |

|---|---|

| Temperature Control | Maintains exact 1100°C for solid-state phase transformation |

| Atmosphere Control | Provides sealed Argon environment to prevent material oxidation |

| Thermal Uniformity | Ensures consistent reaction rates across the precursor mixture |

| Programmable Profiles | Manages precise ramp, dwell, and cooling for reproducibility |

Elevate Your Material Research with KINTEK

Precise atmospheric control and thermal uniformity are non-negotiable for synthesizing advanced mechanoluminescent materials. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or industrial requirements.

Whether you are refining Bi-doped phosphors or developing next-generation ceramics, our high-temperature lab furnaces provide the stability and purity your project demands. Contact us today to find your custom furnace solution.

Visual Guide

References

- Changying Sun, Jing‐Tai Zhao. Stress Distributions and Luminescent Responses of Mechanoluminescent Cylinders with Various Sizes and Loading Paths. DOI: 10.3390/ma18020331

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing