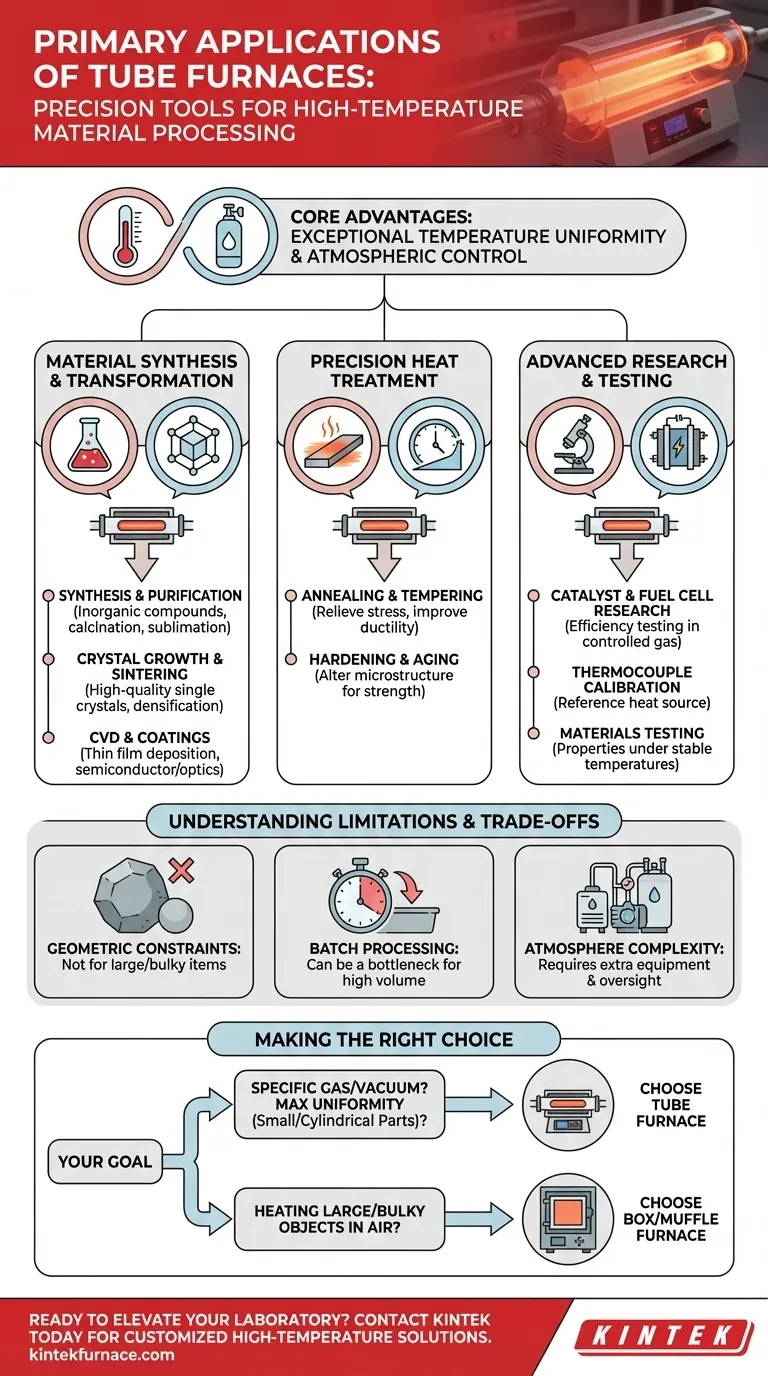

At their core, tube furnaces are precision tools for high-temperature material processing. They are primarily used for synthesizing compounds, performing various types of heat treatment, and conducting experiments in tightly controlled atmospheres. Their applications span materials science, chemistry, and engineering, from synthesizing new materials to purifying existing ones.

A tube furnace is selected not simply for its ability to get hot, but for its unique capacity to provide exceptional temperature uniformity and atmospheric control within its enclosed tubular chamber. This combination is what makes it indispensable for sensitive and repeatable thermal processes.

Material Synthesis and Transformation

The fundamental purpose of a tube furnace is to use heat to change a material's chemical or physical state. Its design is uniquely suited for processes where containment and atmospheric purity are paramount.

Synthesis and Purification

The sealed environment of a work tube is ideal for creating or purifying compounds. Reactant gases can be introduced, and volatile byproducts can be contained or safely vented. This is common for inorganic compound synthesis, calcination (heating to remove impurities), and sublimation for purification.

Crystal Growth and Sintering

Growing high-quality single crystals requires a highly stable and uniform temperature zone. A multi-zone tube furnace provides the precise thermal gradients needed to control the crystallization process. Similarly, sintering—the process of densifying a powder into a solid mass below its melting point—relies on this same uniformity to prevent cracking and ensure consistent density.

Chemical Vapor Deposition (CVD) and Coatings

Tube furnaces serve as ideal chemical reactors for CVD. Precursor gases are flowed through the heated tube, where they react and deposit a thin film onto a substrate. This method is fundamental for creating specialized coatings in the semiconductor and optics industries.

Precision Heat Treatment

Many materials require specific thermal cycles to achieve desired mechanical or physical properties. The excellent temperature control and defined heating/cooling profiles of a tube furnace make it perfect for these tasks.

Annealing and Tempering

Annealing is used to relieve internal stresses, soften a material, and improve its ductility. It involves heating a material to a specific temperature and then cooling it slowly. A programmable tube furnace can execute these precise cooling ramps perfectly. Tempering is a similar process used to increase the toughness of hardened metals.

Hardening and Aging

Hardening and aging are heat treatments that alter a material's microstructure to increase its strength and hardness. These processes often require holding a material at a precise temperature for a specific duration, a task for which the stability of a tube furnace is essential.

Advanced Research and Testing

In a laboratory setting, the tube furnace is a versatile platform for analysis and experimentation where environmental control is a non-negotiable requirement.

Catalyst and Fuel Cell Research

When testing the efficiency of a catalyst, researchers need to pass a specific gas mixture over the catalytic material at a precise temperature. A tube furnace provides the perfect enclosed reactor to control these variables. This same principle applies to testing components for fuel cells under simulated operating conditions.

Thermocouple Calibration and Materials Testing

Because of their proven thermal uniformity, tube furnaces are often used as a reference heat source to calibrate temperature sensors like thermocouples. They are also used to test a material's properties—such as expansion, conductivity, or degradation—at specific, stable temperatures.

Understanding the Limitations and Trade-offs

While incredibly versatile, a tube furnace is not the universal solution for all heating applications. Understanding its limitations is key to using it effectively.

Geometric Constraints

The most obvious limitation is the geometry. A tube furnace is ideal for processing small samples, powders, wafers, or cylindrical parts like shafts and strips that fit easily inside the work tube. It is impractical for heating large, bulky, or irregularly shaped objects.

Batch Processing Model

Most standard tube furnaces are designed for batch processing. Samples are loaded, the process is run, and then the samples are unloaded. This is perfect for research and development but can be a bottleneck for high-volume industrial manufacturing, which often requires a continuous process.

Atmosphere Control Complexity

While the ability to control the atmosphere is a primary advantage, it also adds complexity. Achieving a high vacuum or maintaining a specific, high-purity gas environment requires external equipment like pumps, mass flow controllers, and gas mixers, adding cost and operational oversight.

Making the Right Choice for Your Process

Your specific goal determines whether a tube furnace is the appropriate tool.

- If your primary focus is processing samples in a specific gas or vacuum: A tube furnace is the ideal choice due to its easily sealed and controlled environment.

- If your primary focus is achieving maximum temperature uniformity for small or cylindrical parts: A multi-zone tube furnace offers unparalleled precision for processes like annealing or crystal growth.

- If your primary focus is simply heating large, bulky, or irregularly shaped objects in air: A box or muffle furnace is a more practical and cost-effective solution.

Ultimately, understanding these core principles allows you to select the thermal processing tool that best aligns with your material and your desired outcome.

Summary Table:

| Application Area | Key Processes | Key Features |

|---|---|---|

| Material Synthesis | Inorganic synthesis, calcination, sublimation, CVD | Sealed environment, atmospheric control, temperature uniformity |

| Heat Treatment | Annealing, tempering, hardening, aging | Precise temperature control, programmable profiles |

| Research & Testing | Catalyst studies, fuel cell testing, thermocouple calibration | Versatile platform, stable thermal conditions |

Ready to elevate your laboratory's capabilities? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse product line including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements—whether for material synthesis, heat treatment, or cutting-edge research. Don't settle for less; contact us today to discuss how KINTEK can optimize your thermal processes and drive innovation in your lab!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the advantages of a vacuum tube? Unlock Superior Performance in Audio & Heat Treatment

- What role do rotary tube furnaces play in the building materials industry? Essential for High-Temperature Material Processing

- What are the specifications for large volume single zone tube furnaces? Find Your Ideal High-Temp Solution

- What core functions does a tube high-temperature furnace perform? Mastering In-situ Carbothermal Reduction

- Why are vacuum sealing and quartz tubes needed for FeSiBPCCuNb heat treatment? Achieve Pure Magnetic Properties

- What is the difference between heating zone length and constant temperature zone in tube furnaces? Optimize Your Thermal Processing

- What are the advantages of using a condensing tube furnace for magnesium extraction? Achieve High Purity and Efficient Metal Recovery

- How does a laboratory tube furnace regulate the positioning of platinum (Pt) atoms? Mastering Atomic-Scale Engineering