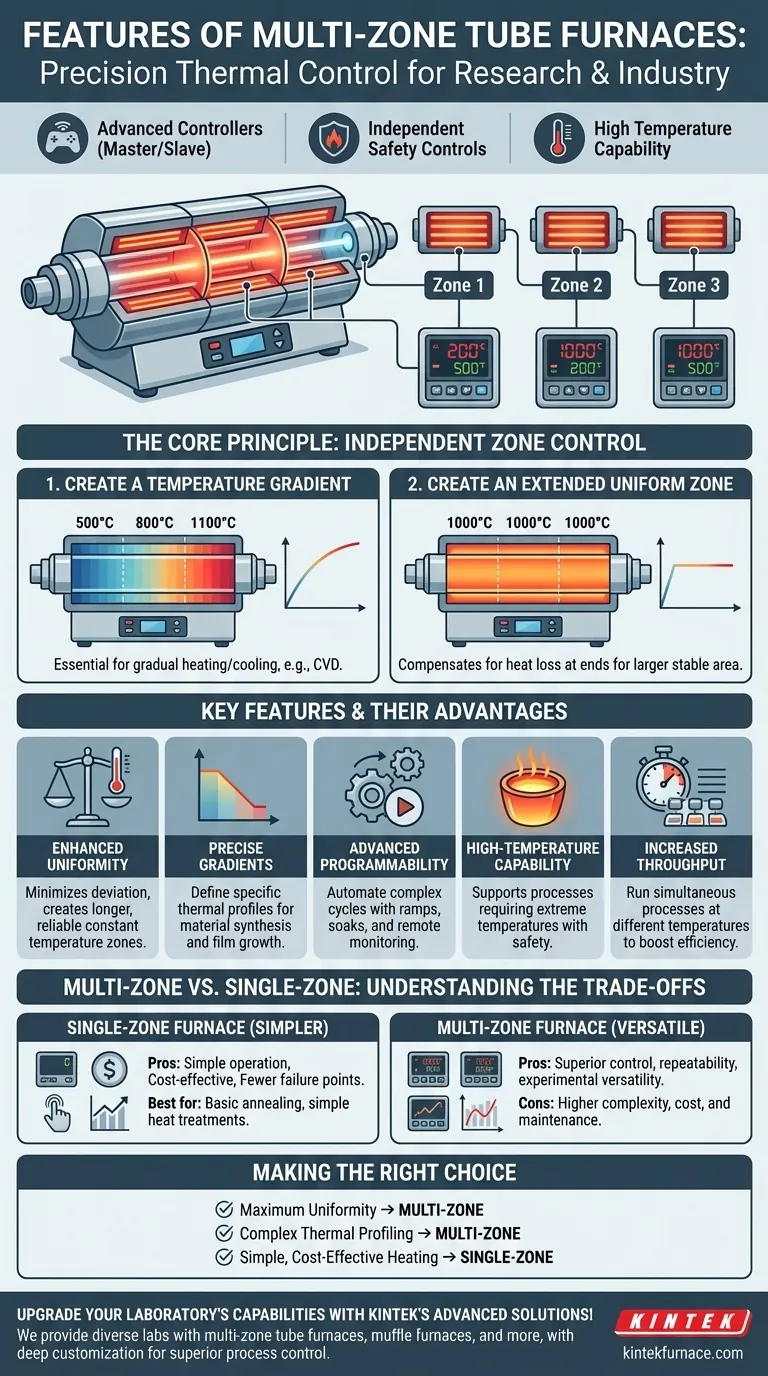

At their core, multi-zone tube furnaces are defined by multiple, independently controlled heating zones along the length of the process tube. Key features include advanced controllers with master/slave programming, independent over-temperature safety controls, and the ability to reach very high temperatures. This design provides superior control over the thermal profile within the furnace.

The fundamental advantage of a multi-zone furnace is its versatility. It can be configured to create either a highly precise temperature gradient or a longer, more stable uniform temperature zone than is possible with a single-zone furnace.

The Core Principle: Independent Zone Control

A multi-zone furnace moves beyond the simple "on/off" heating of a single-zone model. It divides the heated length into distinct sections, each with its own thermocouple and controller.

What "Multi-Zone" Means

Each zone acts like a small, independent furnace. This allows you to apply different temperatures to different sections of your sample simultaneously.

Common configurations are two-zone or three-zone, but more can be used for highly specialized applications.

The Two Primary Operating Modes

The independent zones unlock two powerful capabilities that are mutually exclusive during any single process.

First, you can create a temperature gradient, where each zone is set to a different temperature. This is essential for processes that require a gradual heating or cooling profile along the sample's length.

Second, you can create an extended uniform zone. By setting all zones to the same temperature, the furnace actively compensates for heat loss at the ends, resulting in a much larger and more stable area of uniform temperature.

Key Features and Their Advantages

The physical design of a multi-zone furnace enables specific benefits that improve process quality, efficiency, and repeatability.

Enhanced Temperature Uniformity

When all zones are set to the same temperature, the end zones work harder to counteract natural heat loss. This minimizes temperature deviation and creates a longer, more reliable constant temperature zone for your sample.

Precise Temperature Gradients

For processes like Chemical Vapor Deposition (CVD), the ability to set a specific temperature slope is critical. Multi-zone control allows you to precisely define the thermal profile needed for film growth or material synthesis.

Advanced Programmability and Automation

These furnaces feature sophisticated digital controllers that allow for precise step programming. You can automate complex heat treatment cycles with multiple ramps and soaks, often with options for remote monitoring and data logging.

Increased Throughput and Efficiency

A single multi-zone furnace can sometimes be used to run simultaneous processes at different temperatures. This increases experimental throughput and minimizes errors that can arise from transferring samples between different furnaces.

Understanding the Trade-offs: Multi-Zone vs. Single-Zone

While powerful, a multi-zone furnace is not always the necessary choice. Understanding its trade-offs compared to a simpler single-zone model is key.

When to Choose Single-Zone

For many applications requiring uniform heating, such as basic annealing or simple heat treatments, a single-zone furnace is perfectly adequate. They are simpler to operate, more cost-effective, and have fewer potential points of failure.

The Complexity Factor

The versatility of a multi-zone furnace comes with a higher degree of complexity in programming and setup. Achieving a perfect gradient or an exceptionally uniform zone requires more careful calibration and planning.

Cost and Maintenance

With more heating elements, controllers, and thermocouples, multi-zone furnaces typically have a higher initial purchase price and potentially higher long-term maintenance costs.

Making the Right Choice for Your Process

Your decision should be driven entirely by the thermal requirements of your application.

- If your primary focus is maximum uniformity over a large area: A multi-zone furnace set to a single temperature provides superior results over a single-zone model.

- If your primary focus is complex thermal profiling or gradients: A multi-zone furnace is essential for processes like CVD, crystal growth, and advanced material synthesis.

- If your primary focus is simple, cost-effective uniform heating: A single-zone furnace is often the most practical and efficient choice for basic heat treatments.

Ultimately, choosing a multi-zone furnace is an investment in process control, repeatability, and experimental versatility.

Summary Table:

| Feature | Advantage |

|---|---|

| Independent Zone Control | Enables precise temperature gradients or extended uniform zones for versatile processing |

| Advanced Programmability | Allows automation of complex heat cycles with remote monitoring and data logging |

| Enhanced Temperature Uniformity | Creates larger, stable uniform zones by compensating for heat loss |

| High-Temperature Capability | Supports processes requiring very high temperatures with safety controls |

| Increased Throughput | Facilitates simultaneous processes at different temperatures, boosting efficiency |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with multi-zone tube furnaces, muffle furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for superior process control and efficiency. Contact us today to discuss how our tailored solutions can enhance your thermal processing workflows!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control