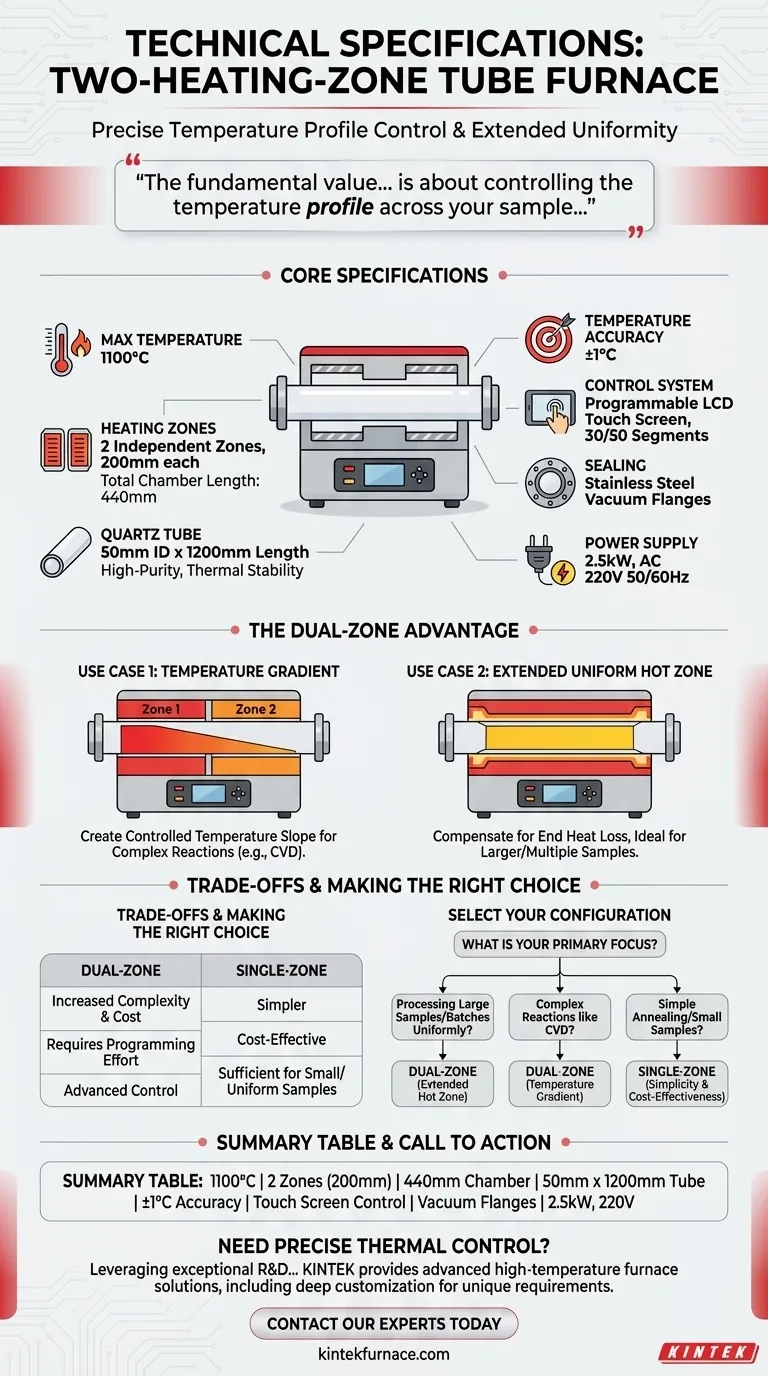

This specific two-heating-zone tube furnace operates up to 1100°C with a high-purity quartz tube (50mm diameter, 1200mm length). Its key feature is two independent 200mm heating zones within a 440mm chamber, controlled by a programmable LCD touch screen. It requires a 2.5kW, 220V power supply and uses stainless steel vacuum flanges for sealing, enabling precise atmospheric control.

The fundamental value of a two-zone furnace isn't just about reaching a temperature; it's about controlling the temperature profile across your sample, allowing you to create a precise gradient or extend the area of uniform heat.

Deconstructing the Core Specifications

To determine if this furnace meets your needs, we must examine its specifications in three key areas: its physical dimensions, thermal capabilities, and control system.

Furnace Tube and Chamber Dimensions

The furnace is built around a high-purity quartz tube with a 50mm inner diameter and a 1200mm total length. This material is excellent for its thermal stability and chemical inertness at high temperatures.

The total furnace chamber length is 440mm. This is the insulated, enclosed section of the furnace that houses the heating elements.

Thermal Performance and Zoning

This model features two independent heating zones, each 200mm long. This dual-zone configuration is the furnace's most critical feature, enabling advanced thermal processing.

Its maximum operating temperature is 1100°C. This makes it suitable for a wide range of applications like annealing, sintering, and material synthesis, but not for ultra-high-temperature ceramics or certain metal treatments.

The furnace maintains a temperature control accuracy of ±1°C, ensuring high precision and repeatability for sensitive experiments.

Control System and Sealing

Temperature is managed by a 30 or 50 segment programmable controller accessed via an HD LCD touch screen. This allows you to design complex heating and cooling cycles with multiple ramps and dwells.

The ends of the tube are sealed with 304 stainless steel vacuum flanges. This is essential for processes requiring an inert gas atmosphere or a vacuum to prevent oxidation or contamination.

Finally, it operates on a standard AC 220V 50/60Hz power supply, consuming 2.5kW of power.

The Core Advantage: Why Two Zones Are Better Than One

A single-zone furnace is a simple workhorse for creating a uniform temperature. A dual-zone furnace, however, offers a level of control that unlocks more sophisticated processes.

Use Case 1: Creating a Temperature Gradient

By setting the two zones to different temperatures, you can create a controlled and stable temperature slope along the length of the tube. This is critical for processes like chemical vapor deposition (CVD), where different reaction stages must occur at different temperatures.

Use Case 2: Extending the Uniform Hot Zone

A common challenge with single-zone furnaces is thermal drop-off near the ends. By setting the two outer zones slightly higher than your target temperature, you can compensate for this heat loss and create a longer, more stable, and more uniform hot zone in the center.

This extended uniformity is vital when processing larger samples or multiple samples that all require identical thermal conditions.

Understanding the Trade-offs

While powerful, a dual-zone furnace is not always the best choice. Understanding its inherent complexities is key to making an informed decision.

Increased Complexity and Cost

A dual-zone system has more heating elements, more thermocouples, and a more advanced controller. This inherently increases the initial cost and potential maintenance complexity compared to a simpler single-zone furnace.

Programming Effort

Leveraging the furnace's capabilities requires more thoughtful programming. You must carefully design the temperature profiles for both zones to achieve the desired gradient or uniformity, which can involve some initial trial and error.

When a Single Zone Is Sufficient

If your work involves small samples that fit comfortably within the uniform hot zone of a single-zone furnace and you do not require temperature gradients, a dual-zone model is likely unnecessary. A single-zone furnace offers simplicity and cost-effectiveness for straightforward, uniform heating applications.

Making the Right Choice for Your Application

Select your furnace configuration based on the specific thermal profile your process demands.

- If your primary focus is processing large samples or batches uniformly: The dual-zone furnace's ability to extend the uniform hot zone is its most significant advantage.

- If your primary focus is complex reactions like CVD: A furnace with multiple, independently controlled zones is not just an advantage—it is a necessity for creating required temperature gradients.

- If your primary focus is simple annealing or material testing on small samples: A less complex and more cost-effective single-zone furnace will likely meet all your requirements.

Ultimately, choosing the right furnace comes down to matching its control capabilities to the precise needs of your material or process.

Summary Table:

| Specification | Details |

|---|---|

| Max Temperature | 1100°C |

| Heating Zones | 2 Independent Zones (200mm each) |

| Chamber Length | 440mm |

| Tube Dimensions | 50mm ID x 1200mm L (Quartz) |

| Temperature Accuracy | ±1°C |

| Control System | Programmable LCD Touch Screen |

| Sealing | Stainless Steel Vacuum Flanges |

| Power Supply | 2.5kW, AC 220V 50/60Hz |

Need precise thermal control for your research?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our dual-zone tube furnace is just one example of our product line, which includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, whether you need an extended uniform hot zone or a complex thermal gradient.

Contact our experts today to discuss how we can tailor a furnace solution to accelerate your materials science or chemistry projects.

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes