For a rotating furnace, the tube assembly that contains and processes the sample is constructed from one of three primary material types: quartz, ceramic (such as corundum/alumina), or specialized high-temperature metal alloys. Each material is chosen for its unique ability to withstand extreme temperatures and chemical interactions while ensuring the integrity of the process.

The selection of a furnace tube material is not a simple matter of availability. It is a critical engineering decision that directly impacts the maximum operating temperature, chemical purity of the sample, and the overall robustness of your process.

Why Material Selection is Critical

The rotating tube is the heart of the furnace. It is the component that directly interacts with your sample, the process atmosphere, and the intense heat generated by the furnace elements.

Its material must perform three functions flawlessly: contain the sample, resist thermal degradation, and remain chemically inert to avoid contaminating the process. An incorrect choice can lead to failed experiments, damaged equipment, or compromised results.

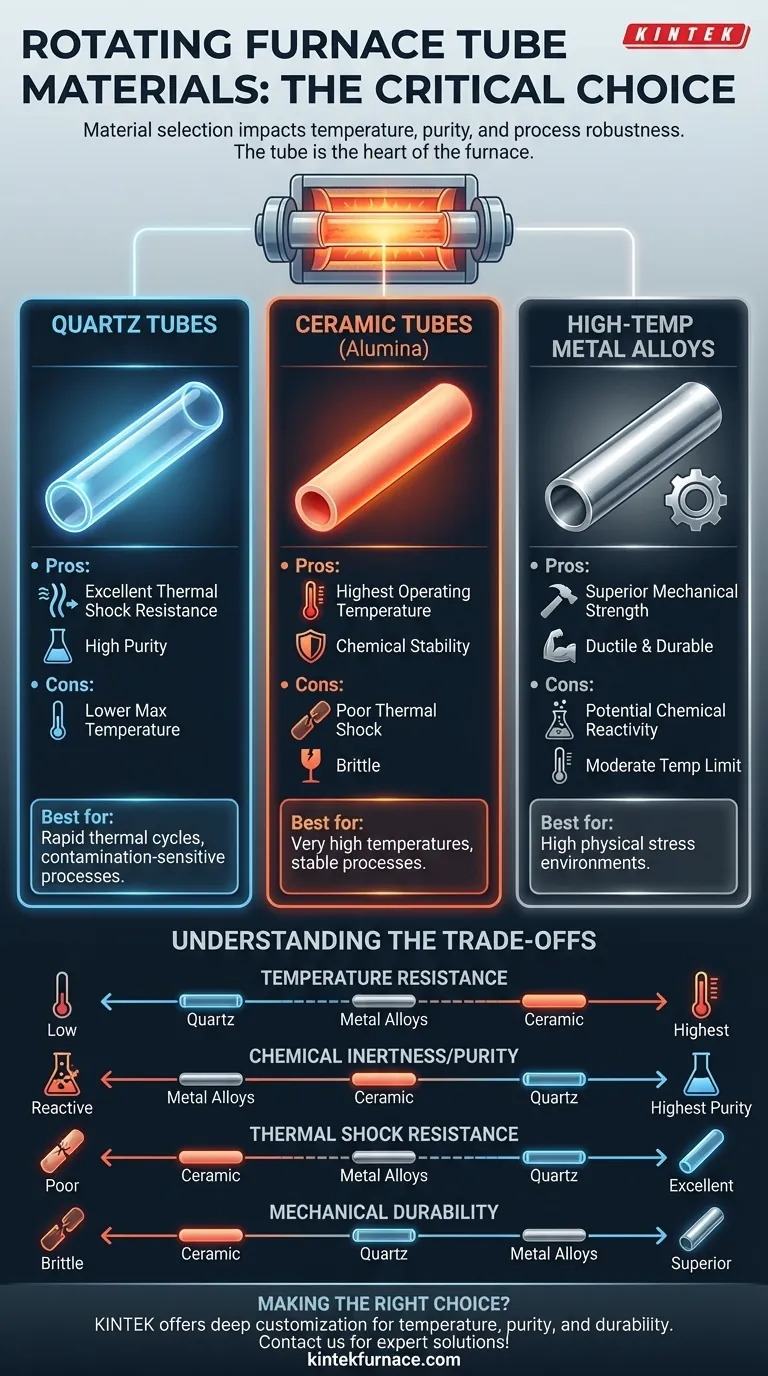

A Breakdown of Your Material Options

Each material offers a distinct profile of strengths and weaknesses. Understanding these differences is key to making the correct choice.

Quartz Tubes

Quartz is a high-purity form of glass (silicon dioxide). It is a common and versatile choice for many laboratory and industrial applications.

Its primary advantage is exceptional thermal shock resistance. Quartz tubes can tolerate rapid heating and cooling cycles far better than ceramics, making them ideal for processes that require speed. They also offer very high purity, minimizing the risk of sample contamination.

The main limitation of quartz is its lower maximum operating temperature compared to high-grade ceramics. It begins to soften at temperatures where alumina ceramics remain rigid and stable.

Ceramic Tubes (Corundum/Alumina)

Ceramic tubes, particularly those made from high-purity alumina (also known as corundum), are the standard for very high-temperature applications.

Their standout feature is an extremely high service temperature, allowing for processes that are impossible with quartz or most metal alloys. They also exhibit excellent chemical stability at these elevated temperatures.

However, ceramics are brittle and have poor resistance to thermal shock. They must be heated and cooled slowly and evenly to prevent cracking. This requires more carefully controlled process cycles.

High-Temperature Metal Alloys

These are materials like Inconel or other nickel-based superalloys, engineered specifically for strength at high temperatures.

The key benefit of metal alloys is their superior mechanical strength and ductility. Unlike quartz or ceramic, they are not brittle and can withstand significant physical stress and impact, making them highly durable.

Their primary drawback is a higher potential for chemical reactivity. The metal can interact with the sample or process atmosphere, potentially introducing contamination. Their maximum temperature, while high, is also typically lower than that of high-purity alumina ceramics.

Understanding the Trade-offs: A Comparative Look

Choosing a material involves balancing competing priorities. There is no single "best" material, only the best material for a specific task.

Temperature Resistance

Your maximum process temperature is the first and most important filter.

- Highest Temperatures: High-purity alumina ceramics are unmatched.

- Moderate-to-High Temperatures: High-temperature metal alloys offer a good balance.

- Lower Temperatures: Quartz is sufficient for many processes and offers other benefits.

Chemical Inertness and Purity

If avoiding sample contamination is your top priority, the choice becomes clear.

- Highest Purity: Quartz offers the most inert environment.

- Excellent Purity: High-purity ceramics are also very stable and non-reactive.

- Potential for Reactivity: Metal alloys present the highest risk of reacting with and contaminating your sample.

Thermal Shock vs. Mechanical Durability

You must consider both thermal and physical stresses.

- Rapid Temperature Changes: Quartz is the superior choice for thermal shock resistance.

- Physical Impact/Stress: Metal alloys are the most durable and resistant to fracture.

- High Sensitivity: Ceramics are brittle and vulnerable to both thermal shock and physical impact.

Making the Right Choice for Your Process

Base your decision on the single most critical factor for your application's success.

- If your primary focus is sample purity and rapid temperature changes: Quartz is the ideal choice, provided your process temperature is within its limits.

- If your primary focus is reaching the highest possible temperatures: High-purity ceramic tubes, such as corundum, are necessary despite their sensitivity to thermal shock.

- If your primary focus is mechanical durability and resistance to physical stress: A high-temperature metal alloy is the most robust option, assuming chemical compatibility with your sample is not an issue.

By carefully evaluating your specific requirements for temperature, purity, and durability, you can select the tube material that ensures the success and reliability of your work.

Summary Table:

| Material Type | Max Temperature | Chemical Inertness | Thermal Shock Resistance | Mechanical Durability |

|---|---|---|---|---|

| Quartz | Lower | Highest | Excellent | Fair |

| Ceramic (Alumina) | Highest | Excellent | Poor | Brittle |

| High-Temp Metal Alloys | Moderate | Lower | Good | Superior |

Struggling to select the right furnace tube material for your unique experimental needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor our products to precisely meet your requirements for temperature, purity, and durability. Contact us today to enhance your lab's efficiency and reliability with our expert solutions!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What factors should be considered when selecting a tube for a rotary tube furnace? Ensure Optimal Performance and Longevity

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What supplementary features can enhance rotary tube furnace performance? Boost Efficiency with Precision Control