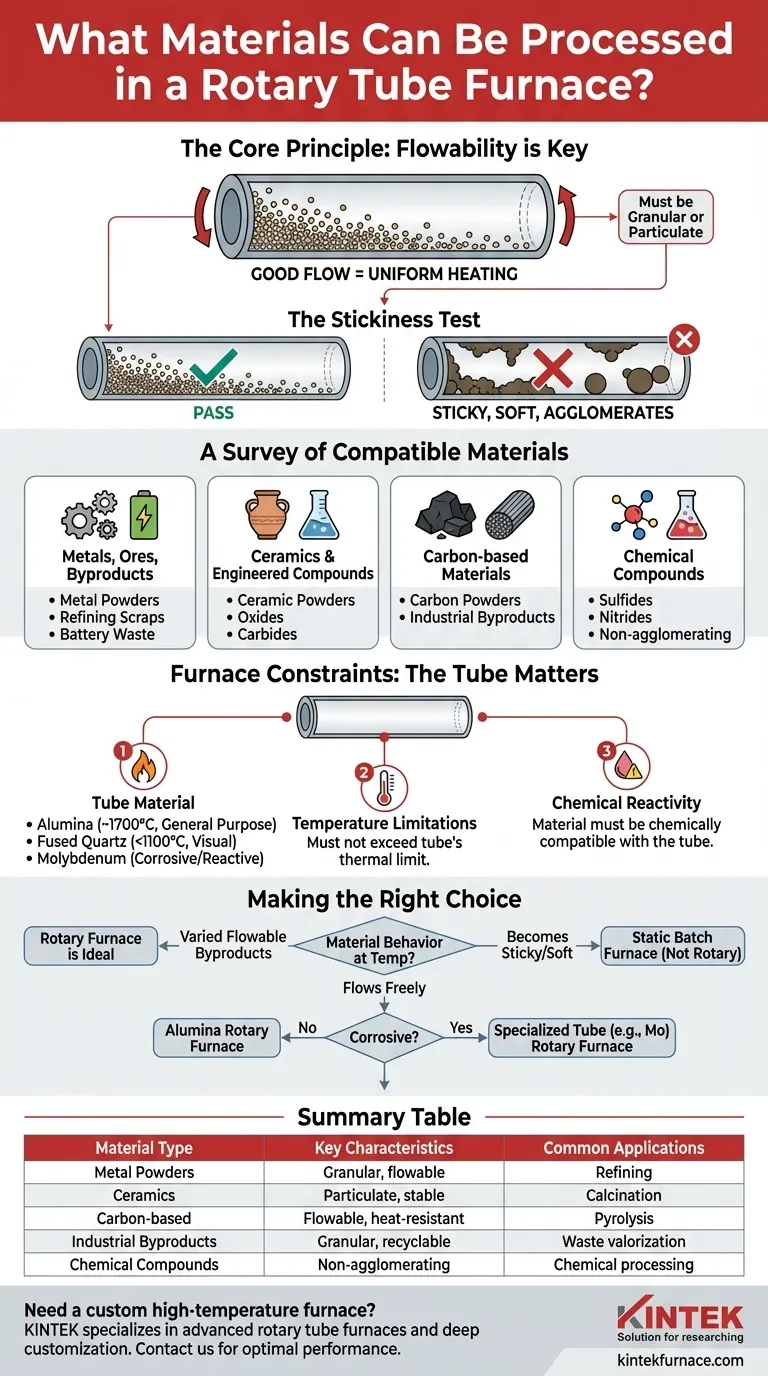

At its core, a rotary tube furnace is designed for the continuous, high-temperature processing of materials that are granular or particulate in form. These include a wide range of substances such as metal powders, ceramics, carbon-based materials, industrial byproducts like battery scraps, and various chemical compounds including oxides, sulfides, and carbides. The essential requirement is that the material must be able to flow and tumble freely when heated, ensuring uniform heat exposure.

The suitability of a material for a rotary tube furnace depends less on its chemical name and more on its physical behavior at high temperatures. If the material can flow without clumping or sticking, and is chemically compatible with the furnace tube, it is likely a good candidate.

The Defining Principle: Material Flow and Form

The function of a rotary tube furnace is dictated by its mechanics. The constant rotation of the tube is what ensures every particle of the material is processed evenly. This mechanical requirement places a fundamental constraint on the type of material you can use.

The Importance of Particulate Form

A rotary furnace works by tumbling the material through a heated zone. For this to be effective, the feed material must be a powder, granule, or small particle. This form maximizes surface area exposure to the controlled atmosphere and heat source.

This tumbling action is what guarantees process uniformity, which is critical for applications like calcination, pyrolysis, or roasting where consistent results are paramount.

The Critical "Stickiness" Test

The single most common reason a material is unsuitable for a rotary tube furnace is that it becomes sticky, soft, or agglomerates at the target processing temperature.

If the material clumps together, it will cease to tumble. Instead, it will either stick to the wall of the tube or form large balls that roll instead of mix, leading to uneven heating, poor results, and potential damage to the furnace.

A Survey of Compatible Materials

Given the primary requirement of flowability, rotary tube furnaces are exceptionally versatile for a wide range of industrial and research applications.

Metals, Ores, and Byproducts

These furnaces excel at processing metal-bearing materials. Common examples include refining lead ore, processing blast furnace waste, and recovering materials from refining dross or battery scraps.

Ceramics and Engineered Compounds

The precise temperature and atmosphere control makes these furnaces ideal for creating or altering engineered materials. This includes processing ceramics, glass powders, oxides, sulfides, nitrides, and carbides.

Industrial Powders and Waste Streams

Rotary furnaces are often used in recycling and waste valorization. They can effectively process materials like bag house powder and other granular byproducts from industrial processes, turning them into valuable resources.

Understanding the Trade-offs: The Furnace Itself is a Constraint

The material you wish to process is only half of the equation. The construction of the furnace itself, particularly the reaction tube, imposes its own set of limitations. You must ensure your process material is compatible with the equipment.

The Reaction Tube Material

The tube that contains the material is the heart of the furnace, and its composition is a critical decision factor.

- Alumina: A common choice for high-temperature work (up to ~1700°C), offering good thermal stability. It is an excellent general-purpose option for non-corrosive materials.

- Fused Quartz/Pyrex: Suitable for lower temperature applications where visual observation might be necessary. These materials will soften and deform at temperatures above approximately 1100°C.

- Molybdenum/Tungsten: These metallic tubes are reserved for processes involving highly corrosive or reactive materials that would damage ceramic or quartz tubes.

Temperature Limitations

The maximum operating temperature of the furnace is determined by both its heating elements (e.g., resistance wire, silicon carbide) and, more importantly, the thermal limit of the reaction tube. Processing a material above the tube's rated temperature will cause it to fail.

Chemical Reactivity

You must consider the potential for chemical reactions between your process material and the furnace tube at high temperatures. An aggressive chemical atmosphere or a reactive material can rapidly degrade an incompatible tube, leading to catastrophic failure and process contamination.

Making the Right Choice for Your Material

Your material's properties must be matched to the furnace's capabilities. Use these guidelines to make an informed decision.

- If your primary focus is high-temperature calcination of a non-corrosive powder: An alumina tube furnace is your most reliable choice for its thermal stability.

- If you are processing chemically aggressive materials or require a specific reactive atmosphere: You must select a furnace with a specialized tube, such as molybdenum, to prevent equipment degradation.

- If your material becomes soft or sticky at processing temperatures: A rotary tube furnace is not suitable; a static batch furnace is a more appropriate alternative.

- If you need to process a variety of industrial byproducts like dross or scrap: The versatility of a rotary furnace is a major advantage, provided the materials can flow freely when heated.

Ultimately, understanding the interplay between your material's behavior and the furnace's physical limits is the key to successful processing.

Summary Table:

| Material Type | Key Characteristics | Common Applications |

|---|---|---|

| Metal Powders | Granular, flowable, non-sticky | Refining, recovery from scraps |

| Ceramics | Particulate form, stable at high temps | Calcination, synthesis |

| Carbon-based Materials | Flowable powders, heat-resistant | Pyrolysis, roasting |

| Industrial Byproducts | Granular, recyclable | Waste valorization, battery scrap processing |

| Chemical Compounds (e.g., oxides, sulfides) | Non-agglomerating, compatible with tube | Chemical processing, material alteration |

Need a custom high-temperature furnace for your materials? KINTEK specializes in advanced rotary tube furnaces and other solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs, ensuring optimal performance for granular and particulate materials. Contact us today to discuss how we can enhance your processing efficiency!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What materials can be used to make the rotating tube assembly of these furnaces? Choose the Best for Your High-Temp Needs

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing

- What types of materials are suitable for processing in rotary tube furnaces? Ideal for Free-Flowing Powders and Granules

- What is the basic construction of a rotary tube furnace? Key Components for Uniform Heating

- What are the common approaches to mixing in rotary furnaces? Boost Uniformity and Efficiency in Thermal Processing