The primary function of a high-vacuum sealed quartz tube is to guarantee a strictly inert reaction environment during the heat treatment of Te1S7/C composites. By physically sealing the sample under vacuum, you eliminate oxygen and moisture, which prevents the chemical degradation of sulfur and tellurium while ensuring they successfully infiltrate the carbon host.

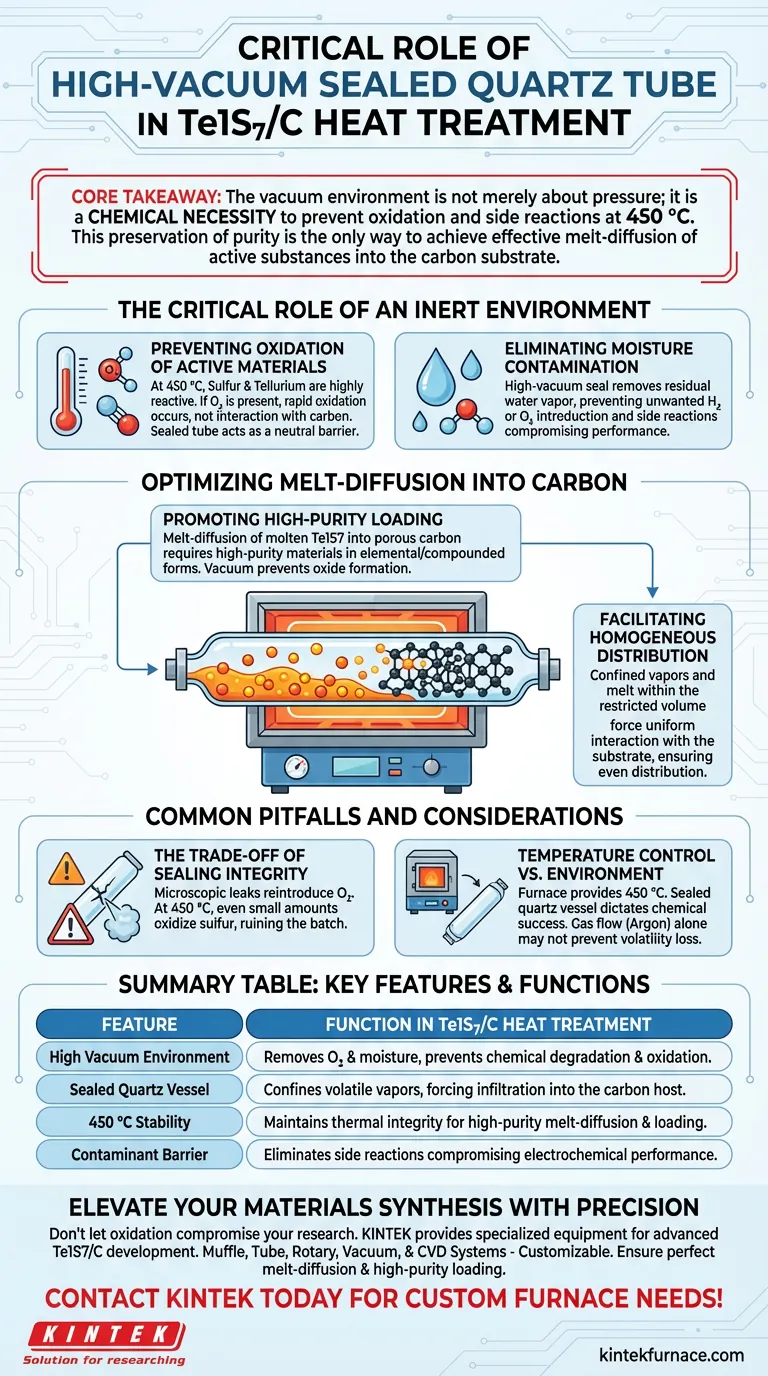

Core Takeaway The vacuum environment is not merely about pressure; it is a chemical necessity to prevent oxidation and side reactions at 450 °C. This preservation of purity is the only way to achieve effective melt-diffusion of active substances into the carbon substrate.

The Critical Role of an Inert Environment

Preventing Oxidation of Active Materials

At the target temperature of 450 °C, both sulfur and tellurium are highly reactive.

If oxygen is present, these elements will oxidize rapidly rather than interacting with the carbon matrix. The sealed quartz tube acts as a barrier, ensuring the atmosphere remains chemically neutral.

Eliminating Moisture Contamination

Water vapor is a common contaminant that can introduce unwanted hydrogen or oxygen into the synthesis.

A high-vacuum seal removes residual moisture before heating begins. This prevents side reactions that could compromise the electrochemical performance of the final composite.

Optimizing Melt-Diffusion into Carbon

Promoting High-Purity Loading

The ultimate goal of this process is melt-diffusion, where molten sulfur and tellurium infiltrate the porous carbon substrate.

For this mechanism to work, the active materials must remain in their elemental or compounded forms. The vacuum ensures that what loads into the carbon is high-purity Te1S7, rather than oxides or byproducts.

Facilitating Homogeneous Distribution

A sealed environment prevents the loss of volatile components.

By confining the vapors and melt within a restricted volume, the materials are forced to interact with the carbon substrate. This results in a more uniform distribution of the active material throughout the composite.

Common Pitfalls and Considerations

The Trade-off of Sealing Integrity

While quartz is excellent for thermal stability, the effectiveness of this method relies entirely on the quality of the seal.

A microscopic leak during the heating phase will reintroduce oxygen. At 450 °C, even a small amount of oxygen can ruin the entire batch by oxidizing the sulfur.

Temperature Control vs. Environment

It is important to distinguish the role of the tube from the role of the furnace.

While the tube furnace provides the precise temperature control needed to reach 450 °C, it is the sealed quartz vessel inside it that dictates the chemical success of the synthesis. Relying on gas flow (like Argon) without a sealed tube may not be sufficient to prevent volatility loss for this specific composite.

Making the Right Choice for Your Synthesis

To maximize the quality of your Te1S7/C composites, prioritize the integrity of your vacuum seal.

- If your primary focus is chemical purity: Ensure the quartz tube is evacuated to a high vacuum before sealing to completely eliminate oxygen and prevent surface oxidation of the tellurium and sulfur.

- If your primary focus is effective loading: Maintain the heat treatment strictly at 450 °C to ensure the viscosity of the melt allows for deep diffusion into the carbon pores without degrading the components.

The success of your composite relies on isolating your reactive elements from the atmosphere the moment heat is applied.

Summary Table:

| Feature | Function in Te1S7/C Heat Treatment |

|---|---|

| High Vacuum Environment | Removes O2 and moisture to prevent chemical degradation and oxidation. |

| Sealed Quartz Vessel | Confines volatile vapors to force infiltration into the carbon host. |

| 450 °C Stability | Maintains thermal integrity for high-purity melt-diffusion and loading. |

| Contaminant Barrier | Eliminates side reactions that compromise electrochemical performance. |

Elevate Your Materials Synthesis with Precision

Don't let oxidation compromise your research. KINTEK provides the specialized equipment needed for advanced Te1S7/C composite development. Backed by expert R&D and world-class manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory requirements.

Ensure perfect melt-diffusion and high-purity loading with our industry-leading thermal solutions. Contact KINTEK today to discuss your custom furnace needs!

Visual Guide

References

- Yue Zhang, Jian Liu. A Tellurium‐Boosted High‐Areal‐Capacity Zinc‐Sulfur Battery. DOI: 10.1002/advs.202308580

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- Why is a vacuum-sealed quartz glass tube necessary for pyrite precursors? Shielding High-Purity Synthesis

- What are the key benefits of using a tube furnace for material processing? Achieve Precise Heat Control for Superior Results

- What is a high temperature tube furnace? Achieve Precise Heat and Atmosphere Control

- What role does a tube high-temperature furnace play in the synthesis of nano carbon spheres? Unlock sp2 Hybridization

- Why is vacuum encapsulation in a quartz tube necessary for AFA alloys? Ensure Critical Elemental Integrity

- How does a high-temperature tube furnace facilitate the sintering of phosphor ceramic blocks? Master Optical Purity

- What is the role of integrated CO2 sensors in a tube furnace? Enhance Combustion Emission Analysis and Accuracy

- How are tubular furnaces utilized in semiconductor manufacturing? Precision Thermal Processing for High-Yield ICs