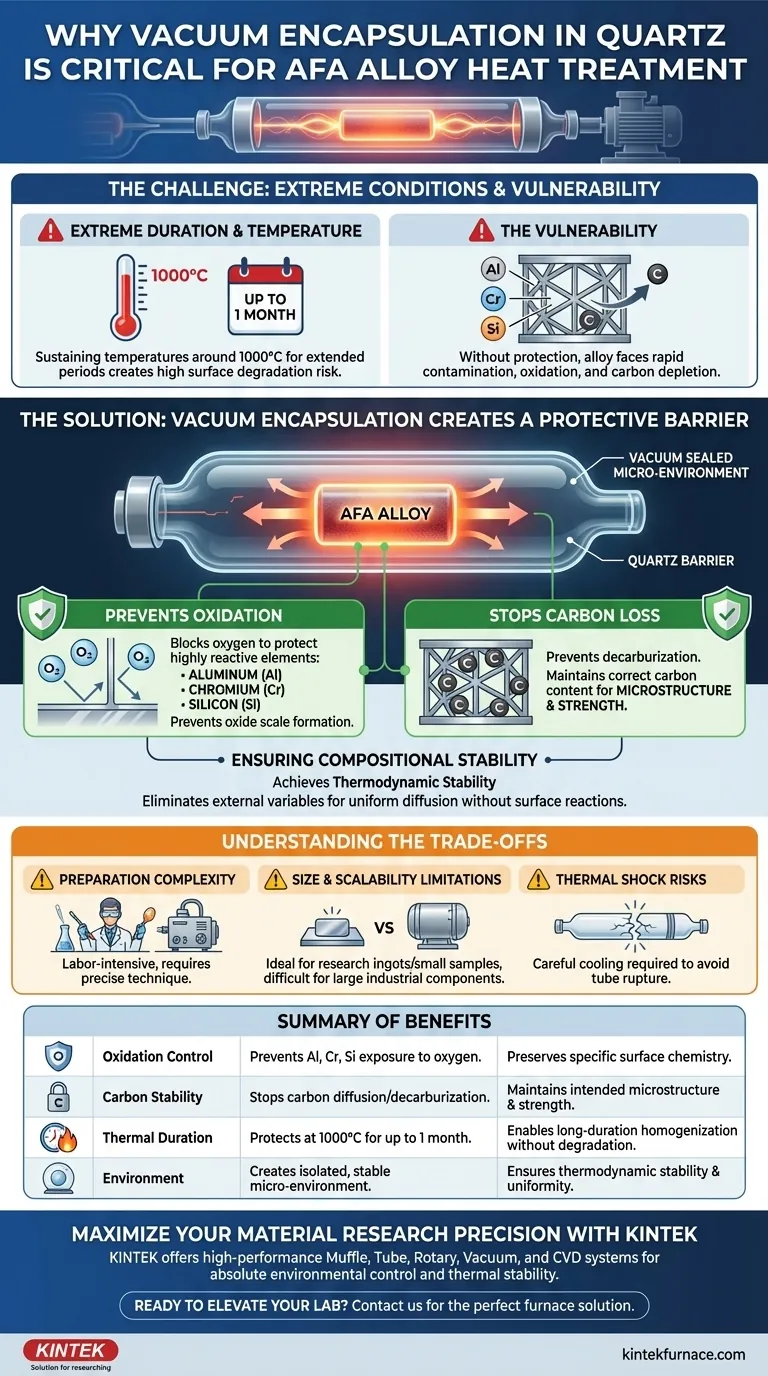

Vacuum encapsulation creates a critical protective barrier required during the extensive heat treatment of Alumina-Forming Austenitic (AFA) alloys. This process serves two primary functions: it prevents the oxidation of highly reactive elements like aluminum, chromium, and silicon, and it effectively stops the loss of carbon from the matrix. By isolating the alloy in a sealed quartz tube, the material maintains its precise chemical composition throughout homogenization annealing, which often involves temperatures of 1000°C for durations as long as one month.

The core challenge of long-duration homogenization is maintaining thermodynamic stability without degradation. Vacuum encapsulation provides an isolated micro-environment that strictly preserves the alloy's elemental balance against atmospheric interference.

The Challenge of High-Temperature Homogenization

To understand why vacuum encapsulation is non-negotiable, you must first understand the aggressive nature of the treatment process itself.

Extreme Duration and Temperature

Homogenization annealing for AFA alloys is not a quick process. It requires sustaining temperatures around 1000°C for extended periods, potentially lasting up to one month.

The Vulnerability of the Matrix

Subjecting metal to this level of thermal energy for weeks creates a high risk of surface degradation. Without protection, the alloy effectively fights a losing battle against the surrounding atmosphere, leading to rapid contamination or depletion of elements.

Preserving Elemental Integrity

The specific chemistry of AFA alloys makes them uniquely susceptible to alteration if not properly isolated.

Protecting Reactive Elements

AFA alloys rely on specific active elements to function, primarily aluminum, chromium, and silicon.

These elements have a high affinity for oxygen. If exposed to air during the annealing process, they will rapidly oxidize, altering the alloy's surface chemistry and potentially compromising its bulk properties.

Preventing Carbon Depletion

Beyond oxidation, maintaining the correct carbon content is vital for the alloy's microstructure and strength.

Vacuum encapsulation prevents carbon loss (decarburization). In an open or inert-gas flow environment, carbon can diffuse out of the metal, but a sealed vacuum environment locks the composition in place.

Ensuring Compositional Stability

The ultimate goal of homogenization is uniformity across the material.

By eliminating external variables like oxygen and nitrogen, the quartz tube ensures that the material achieves thermodynamic stability. This allows the elements to diffuse and settle evenly without being consumed by surface reactions.

Understanding the Trade-offs

While vacuum encapsulation is the gold standard for laboratory-scale homogenization, it introduces specific constraints that must be managed.

Preparation Complexity

Encapsulating samples in high-purity quartz is a manual, labor-intensive process. It requires high-vacuum equipment and precise glass-blowing techniques to ensure a perfect seal without overheating the sample during the sealing process.

Size and Scalability Limitations

Quartz tubes are fragile and have size constraints. This method is ideal for research ingots and small samples but is difficult to scale for large industrial components.

Thermal Shock Risks

Quartz has a low coefficient of thermal expansion, but rapid cooling (quenching) of an encapsulated sample can sometimes lead to tube rupture if not managed carefully, potentially exposing the hot sample to air at the critical final moment.

Ensuring Material Fidelity in Research

When planning your heat treatment strategy for AFA alloys, the method of isolation is as important as the temperature profile.

- If your primary focus is surface integrity: Ensure the vacuum level is sufficient to prevent the depletion of aluminum and chromium, which are prone to forming oxide scales that skew analysis.

- If your primary focus is mechanical strength: Prioritize the seal integrity to prevent carbon loss, as decarburization will significantly lower the hardness and tensile strength of the final material.

Success in AFA alloy development depends on the absolute isolation of the material environment to guarantee that the microstructure you test is the microstructure you intended to create.

Summary Table:

| Feature | Impact of Vacuum Encapsulation | Benefit to AFA Alloys |

|---|---|---|

| Oxidation Control | Prevents exposure of Al, Cr, and Si to oxygen | Preserves the alloy's specific surface chemistry |

| Carbon Stability | Stops carbon diffusion and decarburization | Maintains intended microstructure and strength |

| Thermal Duration | Protects samples at 1000°C for up to 1 month | Enables long-duration homogenization without degradation |

| Environment | Creates an isolated, stable micro-environment | Ensures thermodynamic stability and compositional uniformity |

Maximize Your Material Research Precision with KINTEK

Precise heat treatment of AFA alloys requires equipment that can maintain absolute environmental control. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are customizable to meet your unique laboratory needs.

Whether you are performing long-duration homogenization or complex vacuum encapsulation, our advanced high-temperature furnaces provide the thermal stability and reliability necessary for industrial-grade results.

Ready to elevate your lab's capabilities? Contact us today to find the perfect furnace solution for your research!

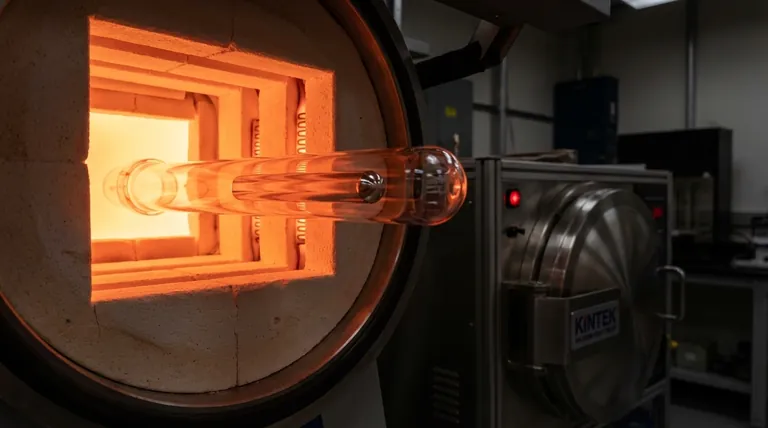

Visual Guide

References

- Qingfeng Jia, Xuping Su. Effect of Si on Mechanical Properties and Oxide Film Formation of AFA Alloy at Low Oxygen Pressure. DOI: 10.3390/coatings15050602

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- How does an atmosphere tube furnace support energy conservation and environmental protection? Boost Efficiency and Cut Emissions

- How does a Tube Furnace system facilitate the growth of nanoporous graphene? Achieve Precision CVD Results

- What role does a vacuum tube furnace play in the preparation of wheat straw biochar? Master Controlled Pyrolysis

- What role does a tube furnace play in the preparation of primitive pomelo peel carbon (PPC)? Master Precision Pyrolysis

- What are the key features of an alumina tube furnace? Achieve Precise High-Temp Processing

- How does a programmable tube furnace facilitate Al/SiC material transformation? Precision Heat for Ceramic Coatings

- How does the heating rate control of a tube furnace affect g-C3N4? Master Precise Thermal Polycondensation

- Why is a secondary high-temperature activation process in a tube furnace necessary? Converting Biochar into CBAC