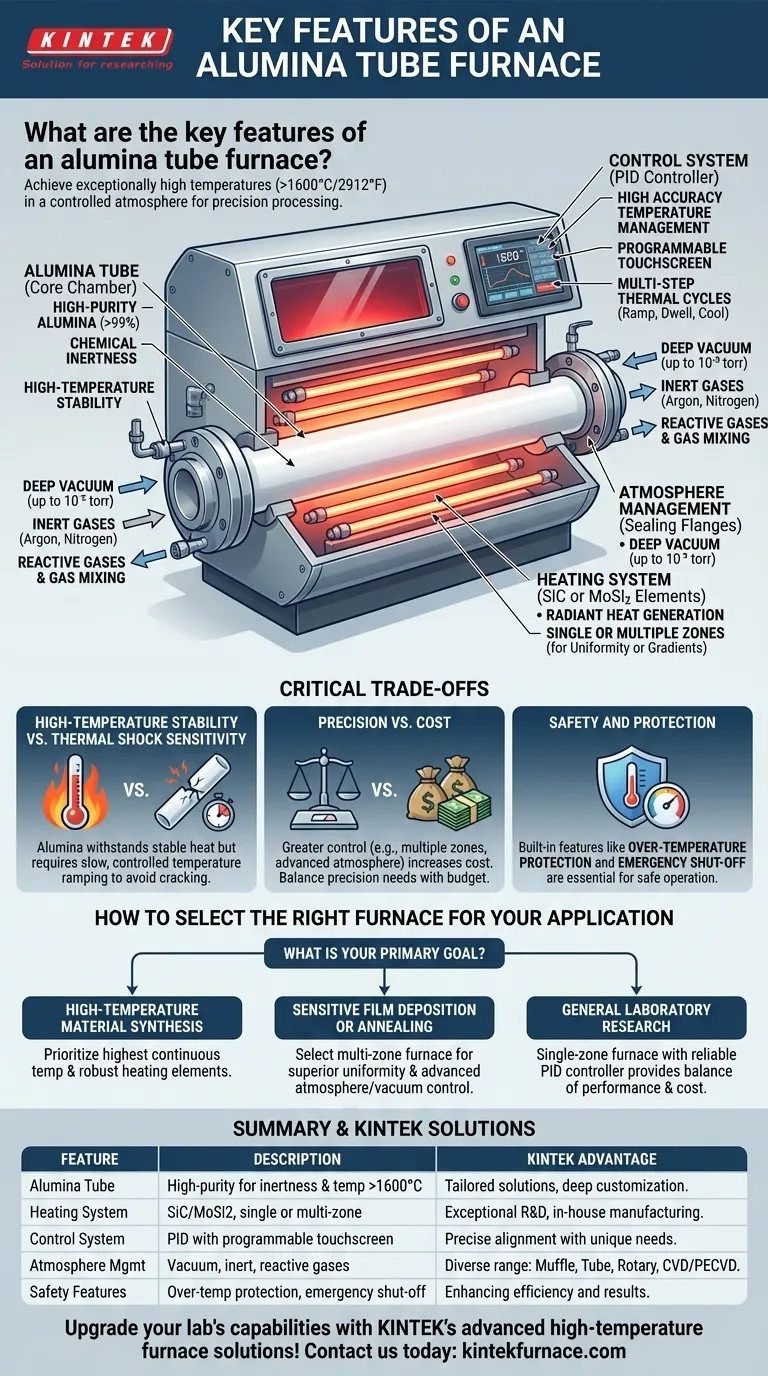

At its core, an alumina tube furnace is a specialized piece of laboratory and industrial equipment defined by its ability to achieve exceptionally high temperatures within a controlled atmosphere. Its key features are derived directly from its central component: a tube made of high-purity aluminum oxide (alumina), which offers excellent chemical inertness and can operate continuously at temperatures exceeding 1600°C (2912°F).

The true value of an alumina tube furnace is not just its heat, but its precision. It provides a chemically stable and highly uniform thermal environment, enabling repeatable and accurate processing of materials under specific atmospheric conditions, from deep vacuum to reactive gases.

Deconstructing the Core Components

A tube furnace's capabilities are a direct result of the interplay between its primary systems. Understanding each component reveals how the furnace achieves its performance.

The Alumina Tube: Heart of the Furnace

The furnace tube is the core chamber where the sample is heated. Made from alumina with a purity often exceeding 99%, it provides the defining chemical and thermal properties of the system.

This high-purity ceramic is responsible for the furnace's excellent chemical inertness and high-temperature stability.

The Heating System: Powering the Process

Heating elements, typically made of robust materials like silicon carbide (SiC) rods or Molybdenum disilicide (MoSi2), are arranged around the outside of the alumina tube.

These elements generate the radiant heat required to reach extreme temperatures. Furnaces may have a single heating zone for general uniformity or multiple zones, each with independent control, for creating precise temperature gradients or an exceptionally uniform flat zone.

The Control System: Ensuring Precision

Modern furnaces use sophisticated PID (Proportional-Integral-Derivative) controllers to manage temperature with high accuracy. These systems use a thermocouple to measure the temperature and constantly adjust the power to the heating elements.

Features often include programmable touchscreens for setting multi-step thermal cycles (ramping, dwelling, and cooling), data logging capabilities, and temperature correction settings.

Atmosphere Management: Creating the Environment

Sealing flanges or end caps are attached to both ends of the tube. These are critical for controlling the internal environment.

This system allows for operation under deep vacuum (as low as 10⁻⁵ torr), an inert gas like argon or nitrogen, or a flow of reactive gases. Advanced setups can include gas mixing systems for creating precise atmospheric compositions.

Understanding the Critical Trade-offs

While powerful, an alumina tube furnace is not without limitations. Acknowledging its trade-offs is essential for successful and safe operation.

High-Temperature Stability vs. Thermal Shock Sensitivity

Alumina is a ceramic. While it can withstand immense, stable heat, it has poor thermal shock resistance.

Heating or cooling the furnace too quickly will create thermal stress that can easily crack the expensive alumina tube. Following a controlled, gradual temperature ramp rate is non-negotiable.

Precision vs. Cost

Greater control and capability come at a higher cost. A simple, single-zone furnace is far more economical than a three-zone model with advanced vacuum pumps and a gas mixing system.

It is crucial to balance the need for precision—such as temperature uniformity over a long zone or complex atmospheric control—with the project budget.

Safety and Protection

Operating at extreme temperatures requires built-in safety mechanisms. Key features include over-temperature protection, which automatically shuts down the furnace if it exceeds a set limit, and emergency shut-off controls.

How to Select the Right Furnace for Your Application

Choosing the correct configuration depends entirely on your primary goal.

- If your primary focus is high-temperature material synthesis: Prioritize a furnace with the highest continuous operating temperature and robust, long-lasting heating elements.

- If your primary focus is sensitive film deposition or annealing: Select a multi-zone furnace for superior temperature uniformity and invest in advanced atmosphere and vacuum control systems.

- If your primary focus is general laboratory research or heat treatment: A single-zone furnace with a reliable PID controller and basic atmosphere capabilities often provides the best balance of performance and cost.

Understanding these core features and trade-offs empowers you to select not just a furnace, but the precise thermal processing tool your work demands.

Summary Table:

| Feature | Description |

|---|---|

| Alumina Tube | High-purity ceramic for chemical inertness and temperatures >1600°C |

| Heating System | SiC or MoSi2 elements with single or multi-zone control |

| Control System | PID controllers with programmable touchscreens for accuracy |

| Atmosphere Management | Supports vacuum, inert, and reactive gases for controlled environments |

| Safety Features | Over-temperature protection and emergency shut-off for safe operation |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored alumina tube furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and results. Contact us today to discuss how we can support your research and industrial processes!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment