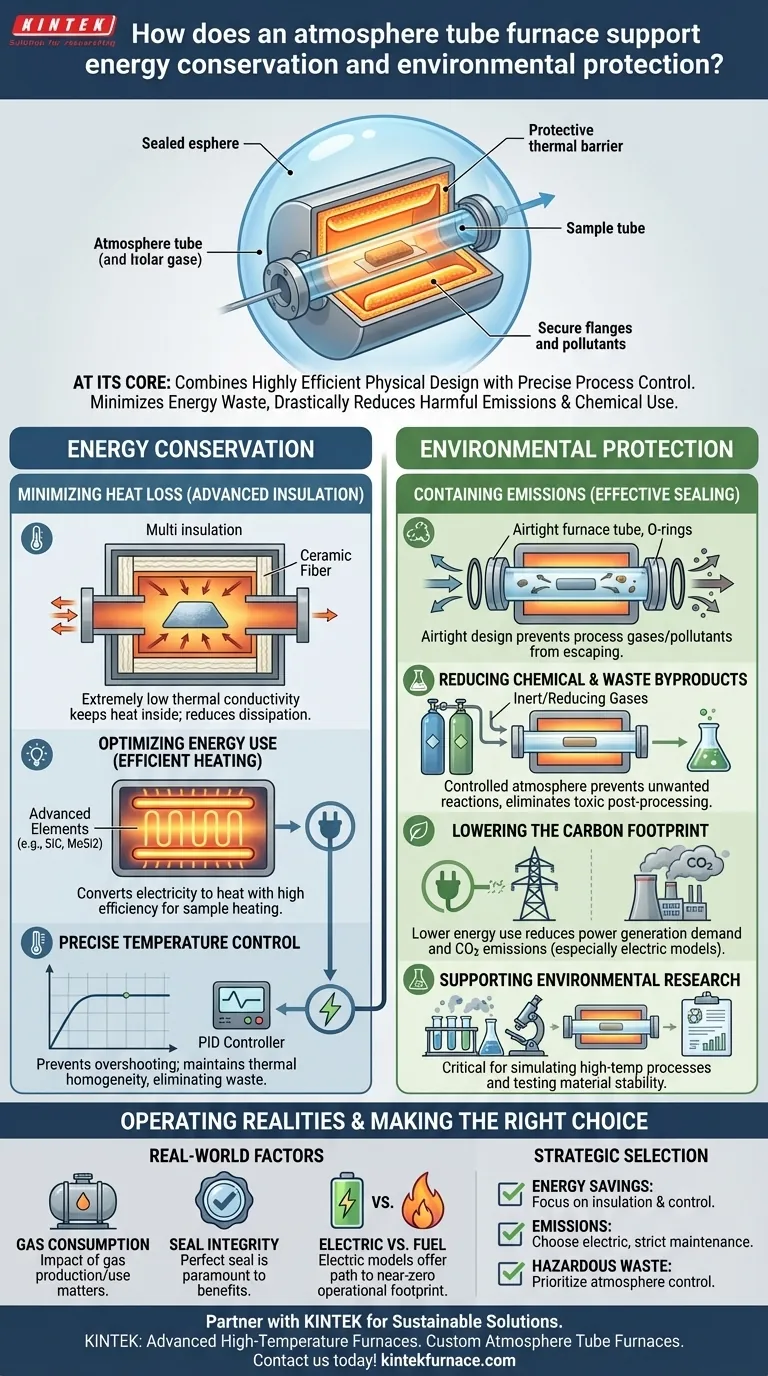

At its core, an atmosphere tube furnace supports energy conservation and environmental protection by combining highly efficient physical design with precise process control. Its superior insulation and advanced heating elements minimize wasted energy, while its sealed chamber and atmosphere management system drastically reduce harmful emissions and the need for hazardous chemical treatments.

An atmosphere tube furnace is not simply a heater; it is a highly contained and controlled environment. This fundamental principle of containment is the key to both its energy efficiency and its eco-friendly operation, allowing it to use less energy and release fewer pollutants than conventional open-air systems.

The Core Principles of Energy Conservation

An atmosphere tube furnace is engineered from the ground up to maximize thermal efficiency. This is not a single feature, but the result of several integrated systems working together.

Minimizing Heat Loss with Advanced Insulation

The primary mechanism for energy conservation is the reduction of heat loss. The furnace chamber is lined with high-grade, multi-layer ceramic fiber or other advanced insulation materials.

These materials have extremely low thermal conductivity, creating a robust barrier that keeps heat inside the furnace tube where it is needed, rather than allowing it to dissipate into the laboratory.

Optimizing Energy Use with Efficient Heating

Modern tube furnaces use advanced heating elements (like Silicon Carbide or Molybdenum Disilicide) that convert electricity to heat with very high efficiency.

This, combined with intelligent power delivery, ensures that energy is used to heat the sample, not to compensate for systemic inefficiencies.

Preventing Waste with Precise Temperature Control

Precise temperature control, managed by sophisticated PID (Proportional-Integral-Derivative) controllers, prevents the system from overshooting the target temperature.

By maintaining thermal homogeneity and stability, the furnace only draws the exact amount of power required, eliminating the significant energy waste associated with temperature fluctuations.

Mechanisms for Environmental Protection

The environmental benefits of a tube furnace stem directly from its ability to create a controlled, isolated atmosphere, moving away from cruder, more wasteful industrial processes.

Containing Emissions with Effective Sealing

The most direct environmental benefit is its sealed design. High-quality flanges and O-rings ensure the furnace tube is airtight.

This effective sealing prevents process gases, volatile byproducts, or potential pollutants generated during heating from escaping into the environment, also minimizing the consumption of expensive process gases.

Reducing Chemical and Waste Byproducts

By enabling flexible atmosphere control, the furnace can create specific inert (e.g., Nitrogen, Argon) or reducing (e.g., Hydrogen mix) environments.

This controlled atmosphere prevents unwanted oxidation and side-reactions, often eliminating the need for post-processing with toxic chemicals and reducing the generation of hazardous waste.

Lowering the Carbon Footprint

Any reduction in energy consumption directly translates to a lower carbon footprint, especially for electric models powered by a grid that includes fossil fuels.

By simply using less electricity per cycle, the furnace reduces the overall demand for power generation and its associated CO2 emissions.

Supporting Environmental Research

Beyond its operational benefits, the furnace is a critical tool in environmental science. It is used to simulate high-temperature processes like incineration for pollutant analysis and to test material stability in extreme conditions, aiding the development of more resilient and environmentally safe materials.

Understanding the Trade-offs and Operating Realities

While highly efficient, the real-world performance of an atmosphere tube furnace depends on its operation and model specifics.

Gas Consumption Is a Factor

While the furnace contains gases effectively, it still consumes them. The environmental and cost impact of producing, transporting, and using gases like argon, nitrogen, or hydrogen must be considered as part of the total operational footprint.

Seal Integrity is Paramount

The environmental and energy benefits are entirely dependent on a perfect seal. Degraded O-rings or improperly secured flanges can lead to gas leaks, negating the containment benefits and wasting energy as the system struggles to maintain its atmosphere and temperature.

Fuel-Based vs. Electric Models

Some industrial atmosphere furnaces are heated by fuel combustion. While they offer process control, they will always have direct carbon emissions. For maximum environmental benefit, an electrically heated model is superior, as it can be powered by renewable energy sources for a near-zero operational carbon footprint.

Making the Right Choice for Your Goal

To leverage the full potential of an atmosphere tube furnace, align your selection and operational priorities with your primary objective.

- If your primary focus is maximizing energy savings: Prioritize models with the highest quality multi-layer insulation and the most precise temperature control specifications.

- If your primary focus is minimizing direct emissions: Choose an electric-powered model and implement a strict maintenance schedule for all seals and flanges.

- If your primary focus is reducing hazardous waste: Focus on the furnace's atmosphere control system, ensuring it can precisely manage the specific inert or reactive gases your process requires.

Ultimately, choosing the right atmosphere tube furnace is an investment in a more controlled, efficient, and sustainable process.

Summary Table:

| Aspect | Key Features | Benefits |

|---|---|---|

| Energy Conservation | Advanced insulation, efficient heating elements, precise PID control | Minimizes heat loss, optimizes power use, reduces energy waste |

| Environmental Protection | Sealed chamber, atmosphere management, flexible gas control | Lowers emissions, reduces hazardous waste, cuts carbon footprint |

Ready to enhance your lab's sustainability with energy-efficient and eco-friendly furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Atmosphere Tube Furnaces, tailored for diverse laboratory needs. Our products, such as Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, come with strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how we can help you achieve superior energy conservation and environmental protection in your processes!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- How does an inert atmosphere prevent oxidation? Shield Materials from Oxygen Damage

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance