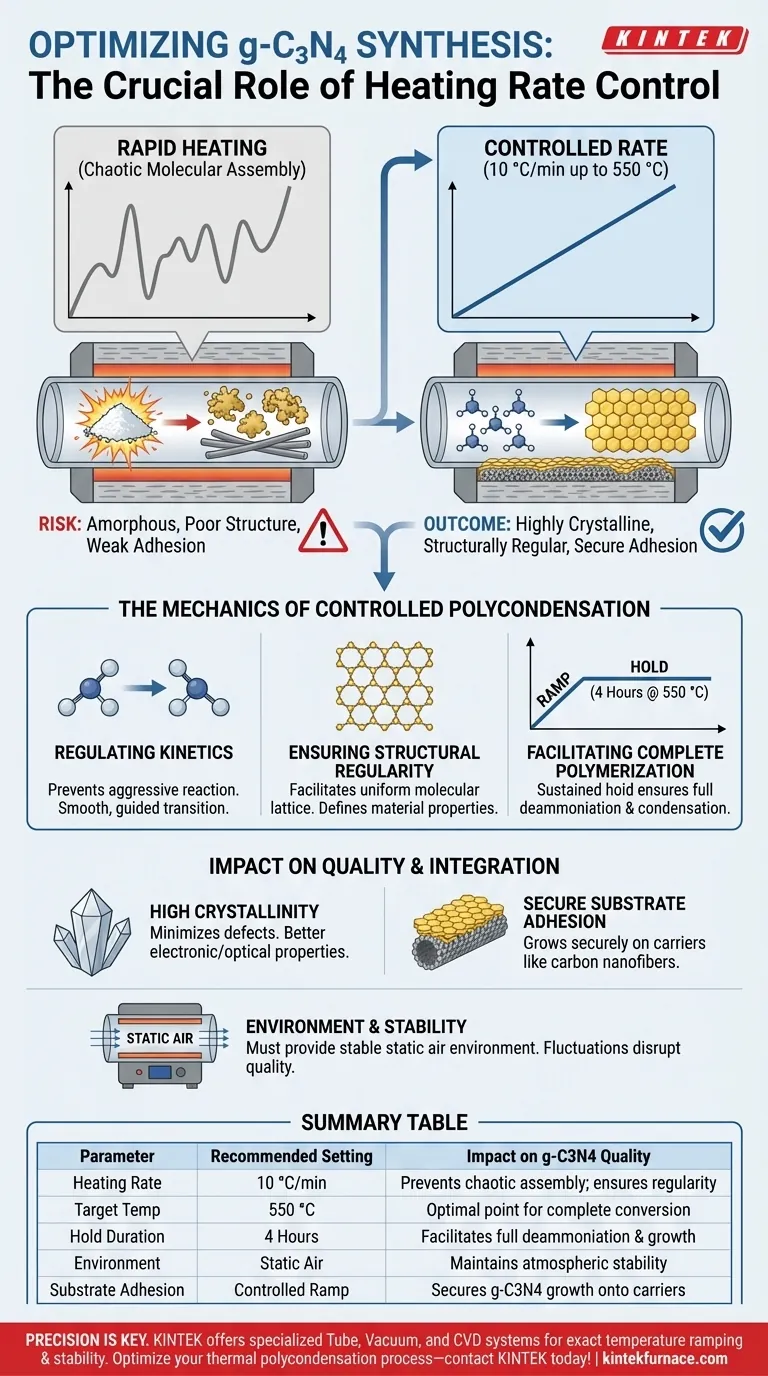

Controlling the heating rate is the decisive factor in guiding the smooth thermal polycondensation of melamine into graphitic carbon nitride (g-C3N4). A precise ramp, specifically 10 °C/min up to 550 °C, ensures the formation of a highly crystalline layer that is structurally regular and adheres securely to carrier substrates like carbon nanofibers.

Precise temperature ramping governs the kinetics of polymerization, preventing chaotic molecular assembly. This controlled approach yields a structurally ordered, two-dimensional carbon nitride framework that integrates robustly with underlying surfaces.

The Mechanics of Controlled Polycondensation

Regulating Reaction Kinetics

The transformation of melamine into g-C3N4 involves a complex series of chemical reactions, including deammoniation and condensation.

By strictly limiting the heating rate to 10 °C/min, you prevent the reaction from proceeding too aggressively.

This accurate control allows the melamine molecules to undergo a smooth, guided transition rather than a chaotic thermal shock.

Ensuring Structural Regularity

A stable heating ramp is essential for creating a uniform molecular lattice.

When the furnace temperature increases steadily, it facilitates the formation of a structurally regular g-C3N4 layer.

This regularity is defined by the material's two-dimensional layered structure, which is critical for its final properties.

Facilitating Complete Polymerization

The process requires not just reaching a target temperature, but arriving there in a way that supports the entire reaction cycle.

Once the target of 550 °C is reached, a holding duration (typically 4 hours) ensures the completion of the condensation reactions.

This combination of a controlled ramp and a sustained hold allows for the full development of the carbon nitride framework.

Impact on Material Quality and Integration

Achieving High Crystallinity

The crystallinity of the final product is directly tied to the precision of the thermal treatment.

Accurate temperature control minimizes defects in the crystal lattice, resulting in a highly crystalline material.

Higher crystallinity typically correlates with better electronic and optical properties in the final semiconductor material.

Securing Substrate Adhesion

One of the most critical aspects of rate control is its effect on how g-C3N4 grows on a support structure.

The primary reference indicates that a controlled rate ensures the g-C3N4 layer grows securely on the surface of carbon nanofiber carriers.

Without this "smooth" polycondensation, the coating may be uneven or fail to adhere properly to the nanofibers.

Understanding the Trade-offs

The Risk of Rapid Heating

While faster heating rates might seem efficient, they jeopardize the integrity of the synthesis.

Deviating from a controlled rate like 10 °C/min can disrupt the "smoothness" of the polycondensation, likely leading to amorphous or poorly organized structures.

If the reaction kinetics are too fast, the material may fail to form the necessary ordered, layered structure.

The Necessity of Environmental Stability

Heating rate cannot be viewed in isolation; it depends on the furnace environment.

As noted in the supplementary data, the furnace must provide a stable static air environment.

Even a perfect heating rate will fail to produce high-quality g-C3N4 if the atmospheric conditions fluctuate or if the hold time is insufficient for complete deammoniation.

Optimizing Your Synthesis Protocol

To ensure reproducibility and high material quality in your g-C3N4 synthesis, consider the following based on your specific objectives:

- If your primary focus is Structural Integrity: Adhere strictly to a 10 °C/min ramp to maximize crystallinity and ensure a regular 2D layered structure.

- If your primary focus is Composite Fabrication: Use the controlled heating rate to guarantee the secure, uniform growth of g-C3N4 onto carriers like carbon nanofibers.

Mastering the heating ramp is the difference between a loose, amorphous powder and a high-performance, crystalline semiconductor.

Summary Table:

| Parameter | Recommended Setting | Impact on g-C3N4 Quality |

|---|---|---|

| Heating Rate | 10 °C/min | Prevents chaotic assembly; ensures structural regularity |

| Target Temperature | 550 °C | Optimal point for complete melamine-to-nitride conversion |

| Hold Duration | 4 Hours | Facilitates full deammoniation and crystal growth |

| Environment | Static Air | Maintains atmospheric stability for uniform polymerization |

| Substrate Adhesion | Controlled Ramp | Secures g-C3N4 growth onto carriers like carbon nanofibers |

Precision is the key to high-performance graphitic carbon nitride synthesis. Backed by expert R&D and manufacturing, KINTEK offers specialized Tube, Vacuum, and CVD systems designed for the exact temperature ramping and stability your research demands. Whether you need a standard setup or a customizable high-temp furnace for unique material applications, our systems ensure superior crystallinity and structural integrity. Optimize your thermal polycondensation process—contact KINTEK today!

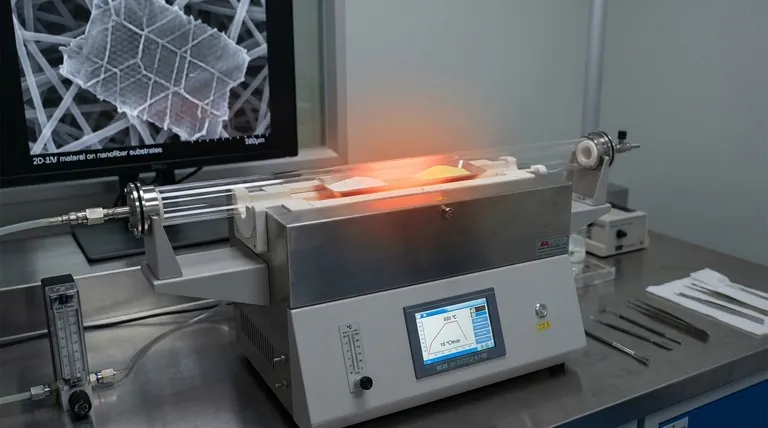

Visual Guide

References

- Jingjing Liu, Lu Gan. Metal-Free Cellulose Carbon Nanofiber Supported Graphitic Carbon Nitride for High-Efficient BPA Degradation by Photcatalytic Peroxymonosulfate Activation. DOI: 10.3390/catal15080788

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How is a laboratory tube furnace applied in synthesis and processing? Unlock Precise Material Control

- What are the safety and usability features of tube furnaces? Essential for Precise Material Processing

- What is the function of autoclaves and tube reactors in hydrometallurgical leaching? Unlock Refractory Ore Potential

- How is a High Temperature Tube Furnace used in material science? Unlock Precise Material Synthesis & Control

- What role does a tube high-temperature furnace play in the synthesis of nano carbon spheres? Unlock sp2 Hybridization

- How does a tube furnace facilitate the transformation of natural wood into a Carbonized Wood carrier? Master Pyrolysis

- What role does a high-temperature tube furnace play in Silicon/Hard Carbon synthesis? Master Battery Anode Production

- What role does a high-temperature tube furnace play in Bi-MOF transformation? Mastering Nanocomposite Synthesis