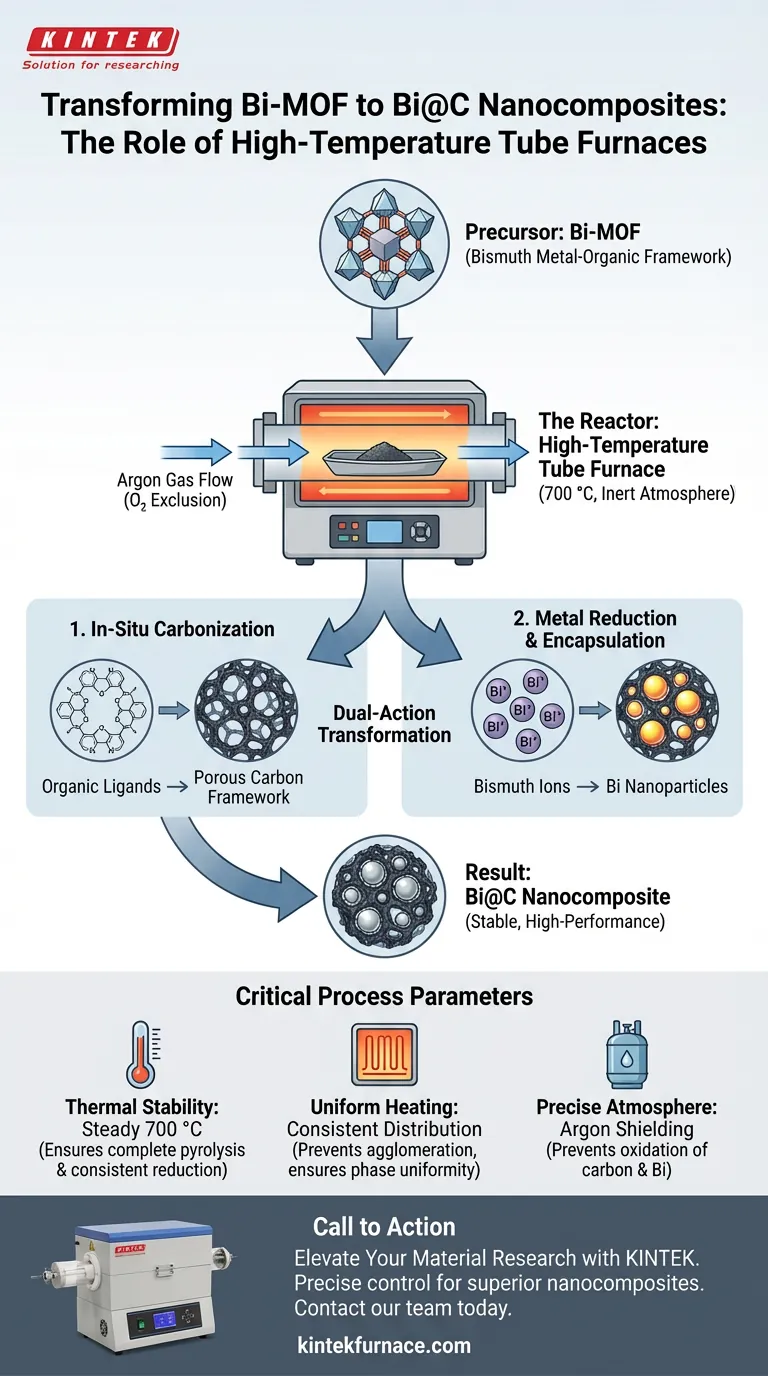

The high-temperature tube furnace serves as the precise reaction vessel for the pyrolytic conversion of Bismuth Metal-Organic Frameworks (Bi-MOF). Its primary role is to maintain a stable, oxygen-free environment—typically shielded by Argon gas—while heating the material to 700 °C. This specific thermal treatment drives the simultaneous carbonization of organic ligands and the reduction of bismuth, resulting in a structured Bi@C nanocomposite.

Core Takeaway The tube furnace enables a dual-action transformation: it decomposes organic ligands into a porous carbon framework while simultaneously reducing the bismuth source into metallic nanoparticles. This "in-situ" process ensures the bismuth is uniformly encapsulated within the carbon, creating a stable, high-performance composite material.

The Mechanism of Transformation

Precise Atmosphere Control

The most critical function of the tube furnace in this process is the exclusion of oxygen.

By purging the chamber with Argon gas, the furnace prevents the combustion of the organic ligands. Instead of burning away, the organic material is forced to undergo thermal decomposition in an inert environment, which is essential for retaining the carbon structure.

In-Situ Carbonization

At the target temperature of 700 °C, the organic ligands within the Bi-MOF structure break down.

This process, known as in-situ carbonization, transforms the ligands into a porous carbon framework. This framework acts as the structural host, providing a conductive matrix and physical support for the metal components.

Metal Reduction and Encapsulation

While the carbon framework forms, the furnace's thermal energy triggers the reduction of the bismuth source.

The bismuth ions are converted into metallic bismuth nanoparticles. Because this happens simultaneously with carbonization, these nanoparticles become uniformly encapsulated within the newly formed carbon matrix, preventing them from clumping together (agglomeration).

Critical Process Parameters

Thermal Stability

The tube furnace must maintain a rigorous temperature profile.

For Bi-MOF transformation, a steady hold at 700 °C is required to ensure complete pyrolysis. Fluctuations in temperature could lead to incomplete carbonization or inconsistent reduction of the bismuth.

Uniform Heating

The geometry of the tube furnace promotes uniform heat distribution across the sample boat.

This ensures that the phase transformation—from MOF crystal to Carbon/Metal composite—occurs evenly throughout the bulk of the material. This uniformity is vital for achieving consistent electrochemical or catalytic performance in the final product.

Understanding the Trade-offs

Atmosphere Sensitivity

The success of this process is entirely dependent on the integrity of the inert atmosphere.

Even a minor leak or insufficient Argon flow can introduce oxygen. This would lead to the oxidation of the carbon (burning it off as CO2) or the formation of unwanted bismuth oxides rather than pure metallic bismuth.

Temperature Constraints

Selecting the exact temperature involves a compromise.

While 700 °C is the standard for this specific Bi-MOF precursor, deviating from this temperature carries risks. Lower temperatures may result in low crystallinity or incomplete reduction, while significantly higher temperatures could cause the bismuth nanoparticles to sinter and grow too large, reducing their active surface area.

Making the Right Choice for Your Goal

When configuring your tube furnace for Bi-MOF pyrolysis, your specific research goals should dictate your parameters.

- If your primary focus is conductivity: Prioritize ensuring a complete oxygen-free atmosphere to maximize the graphitization of the carbon framework without burning it away.

- If your primary focus is nanoparticle size: Strictly control the temperature ramp and hold time at 700 °C to prevent the bismuth particles from coalescing into larger grains.

The tube furnace is not just a heater; it is the atmospheric controller that dictates the chemical identity of your final nanocomposite.

Summary Table:

| Process Function | Description | Impact on Bi@C Nanocomposite |

|---|---|---|

| Inert Atmosphere | Argon shielding at high temps | Prevents carbon combustion; ensures structural integrity |

| In-situ Carbonization | Pyrolysis of organic ligands | Creates a porous, conductive carbon host framework |

| Metal Reduction | Thermal conversion of Bi ions | Produces encapsulated bismuth nanoparticles |

| Uniform Heating | Consistent thermal distribution | Ensures phase uniformity and prevents metal agglomeration |

Elevate Your Material Research with KINTEK

Precise atmospheric control and thermal stability are the difference between a failed experiment and a high-performance nanocomposite. Backed by expert R&D and manufacturing, KINTEK offers high-precision Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of MOF transformation and carbonization.

Ready to achieve superior phase purity and nanoparticle encapsulation? Contact our technical team today to find the perfect high-temperature solution for your lab.

Visual Guide

References

- Xiaoqing Dong, Chaolin Li. Bismuth Nanoparticles Encapsulated in a Porous Carbon Skeleton as Stable Chloride-Storage Electrodes for Seawater Desalination. DOI: 10.3390/batteries10010035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature tube furnace contribute to the performance of carbon nanowire networks? Enhance Electrode Performance

- What is the function of a fast-response photoelectric sensor system? Precision Ignition Timing in Tube Furnaces

- What are the advantages of a fluidized bed vertical tube furnace? Unlock Superior Heat Treatment Efficiency

- Why is a tube furnace used for Solid State Polycondensation? Master Molecular Weight Control in SSP

- What role do rotary tube furnaces play in the building materials industry? Essential for High-Temperature Material Processing

- What factors determine the selection of a three-zone split tube furnace? Key Specs for Precision Thermal Processing

- How do laboratory tube furnaces contribute to the sintering of Ba0.95La0.05(Fe1-xYx)O3-δ? Precise Atmosphere Control

- What heat treatment processes can a 70mm tube furnace be used for? Essential Guide for Material Processing