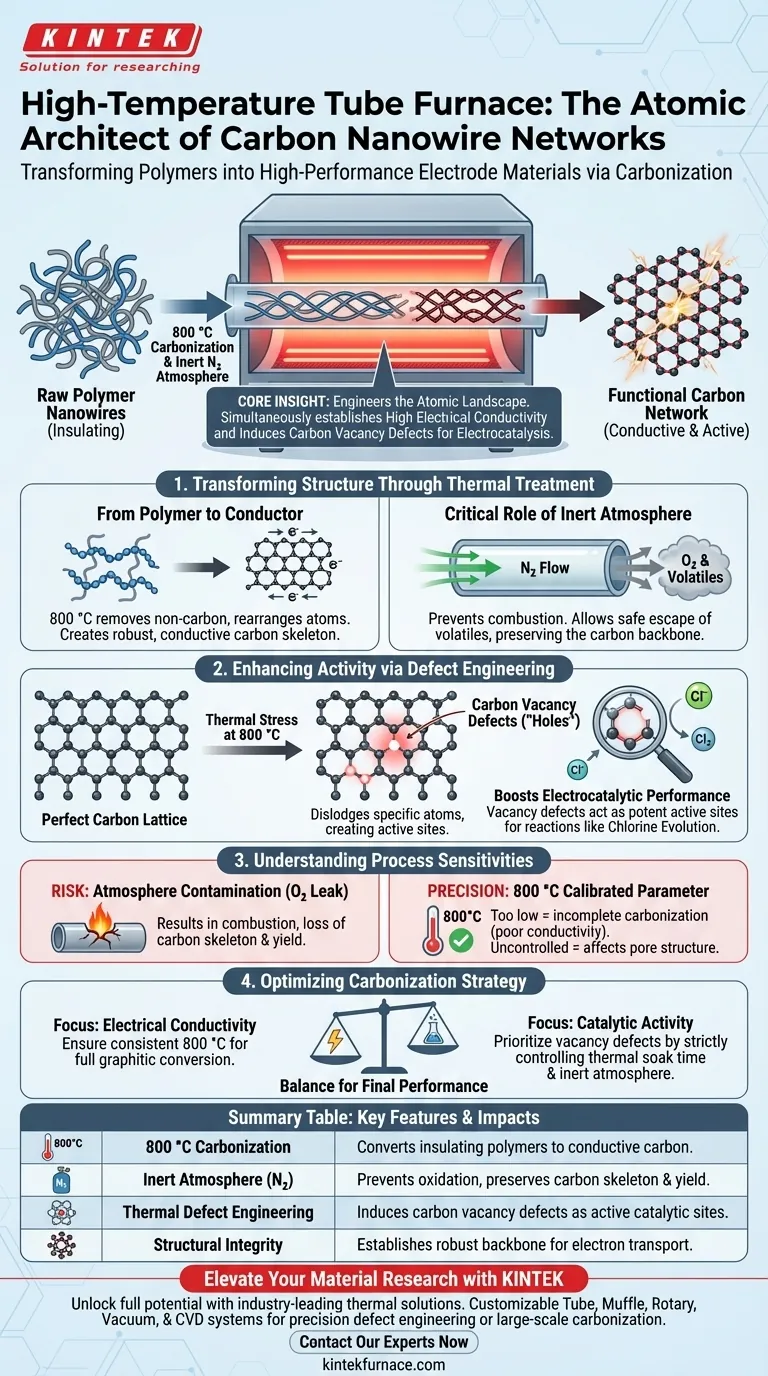

A high-temperature tube furnace serves as the critical transformative tool that converts insulating polymer structures into functional, high-performance electrode materials. By maintaining a stable temperature of 800 °C under a protective nitrogen atmosphere, the furnace carbonizes polypyrrole nanowires, fundamentally altering their atomic structure to create a highly conductive carbon network.

The Core Insight The tube furnace does not simply dry or harden the material; it engineers the atomic landscape. By facilitating carbonization in an inert environment, the process simultaneously establishes high electrical conductivity and induces carbon vacancy defects, which are the essential active sites required for efficient electrocatalytic chlorine evolution.

Transforming Structure Through Thermal Treatment

From Polymer to Conductor

The primary function of the furnace is to drive the carbonization process.

Polypyrrole nanowires are initially polymeric. Subjecting them to 800 °C removes non-carbon elements and rearranges the remaining atoms.

This transformation results in a robust carbon nanowire network that possesses the high electrical conductivity necessary for electron transport during electrochemical reactions.

The Critical Role of the Inert Atmosphere

The furnace must provide a strictly oxygen-free environment, typically using a constant flow of nitrogen.

Without this protective atmosphere, the organic precursors would simply burn (oxidize) rather than carbonize.

The inert gas allows volatile components to escape safely, leaving behind a stable carbon skeleton that serves as the physical backbone of the electrode.

Enhancing Activity via Defect Engineering

Inducing Carbon Vacancy Defects

Beyond simple carbonization, the high thermal energy within the tube furnace performs defect engineering.

At 800 °C, the thermal stress causes specific atoms to dislodge from the carbon lattice, creating "holes" known as carbon vacancy defects.

These are not structural failures; they are intentional features that alter the electronic properties of the material surface.

Boosting Electrocatalytic Performance

The defects created by the furnace significantly increase the material's chemical activity.

Specifically, these vacancy defects act as potent active sites for electrocatalytic chlorine evolution.

By disrupting the perfect carbon structure, the furnace ensures the resulting electrode is not just conductive, but chemically reactive where it matters most.

Understanding Process Sensitivities

The Risk of Atmosphere Contamination

If the tube furnace fails to maintain a strict inert atmosphere (leaking oxygen), the biomass or polymer will undergo combustion.

This results in the loss of the carbon skeleton and a dramatic reduction in the material's structural integrity and yield.

Temperature Precision

The specific temperature of 800 °C is a calibrated parameter, not a random setting.

Temperatures that are too low may result in incomplete carbonization, leading to poor conductivity.

Conversely, uncontrolled heating rates or incorrect temperatures can affect pore structure development, potentially limiting the surface area available for reactions.

Optimizing the Carbonization Strategy

To maximize the performance of carbon nanowire networks, align your thermal treatment with your specific material goals:

- If your primary focus is electrical conductivity: Ensure the furnace maintains a consistent high temperature (800 °C) to fully convert the polymer network into a graphitic-like carbon structure.

- If your primary focus is catalytic activity: Prioritize the creation of vacancy defects by strictly controlling the thermal soaking time and ensuring the atmosphere remains purely inert to protect these active sites.

Ultimately, the tube furnace acts as an atomic architect, balancing the creation of a conductive skeleton with the introduction of catalytic defects to define the material's final performance.

Summary Table:

| Feature | Impact on Carbon Nanowire Networks |

|---|---|

| 800 °C Carbonization | Converts insulating polymers into highly conductive carbon structures. |

| Inert Atmosphere (N2) | Prevents oxidation/combustion, preserving the carbon skeleton and yield. |

| Thermal Defect Engineering | Induces carbon vacancy defects that serve as active catalytic sites. |

| Structural Integrity | Establishes a robust physical backbone for efficient electron transport. |

Elevate Your Material Research with KINTEK

Unlock the full potential of your carbon nanowire networks with KINTEK’s industry-leading thermal solutions. Backed by expert R&D and precision manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production needs.

Whether you are focusing on atomic-level defect engineering or large-scale carbonization, our furnaces provide the temperature precision and atmosphere control essential for superior electrocatalytic results. Empower your lab with KINTEK today.

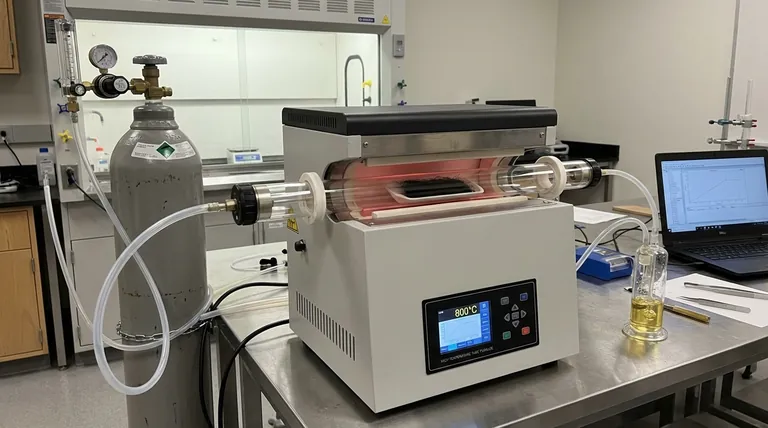

Visual Guide

References

- Cuinan Jiang, Lu Zheng. Carbon‐Based Flexible Electrode for Efficient Electrochemical Generation of Reactive Chlorine Species in Tumor Therapy. DOI: 10.1002/adhm.202500369

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a dual-temperature zone tube furnace control crystal quality? Master PVT for Organic Single Crystals

- What are the benefits of high yield and product concentration in a tube furnace? Boost Efficiency and Purity in Chemical Processes

- What are the typical physical and performance specifications for lab tube furnaces? A Guide to Key Specs

- What core process conditions does a high-temperature tube furnace provide for the rapid pyrolysis of coal?

- How does the injection probe in a Drop Tube Furnace ensure a high heating rate? Simulate Industrial Pyrolysis Expertly

- What are the objectives of using a tube furnace for dual-layer nanocomposite heat treatment? Maximize Coating Stability

- What is the working environment of a vacuum tube furnace? Achieve Purity and Precision in Material Processing

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right High-Temp Solution