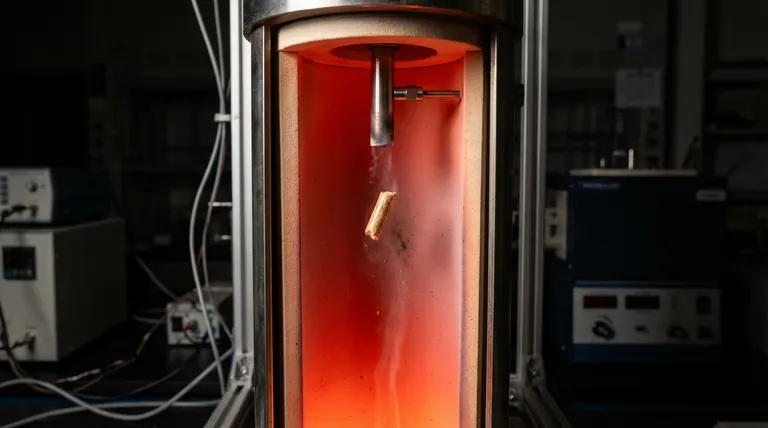

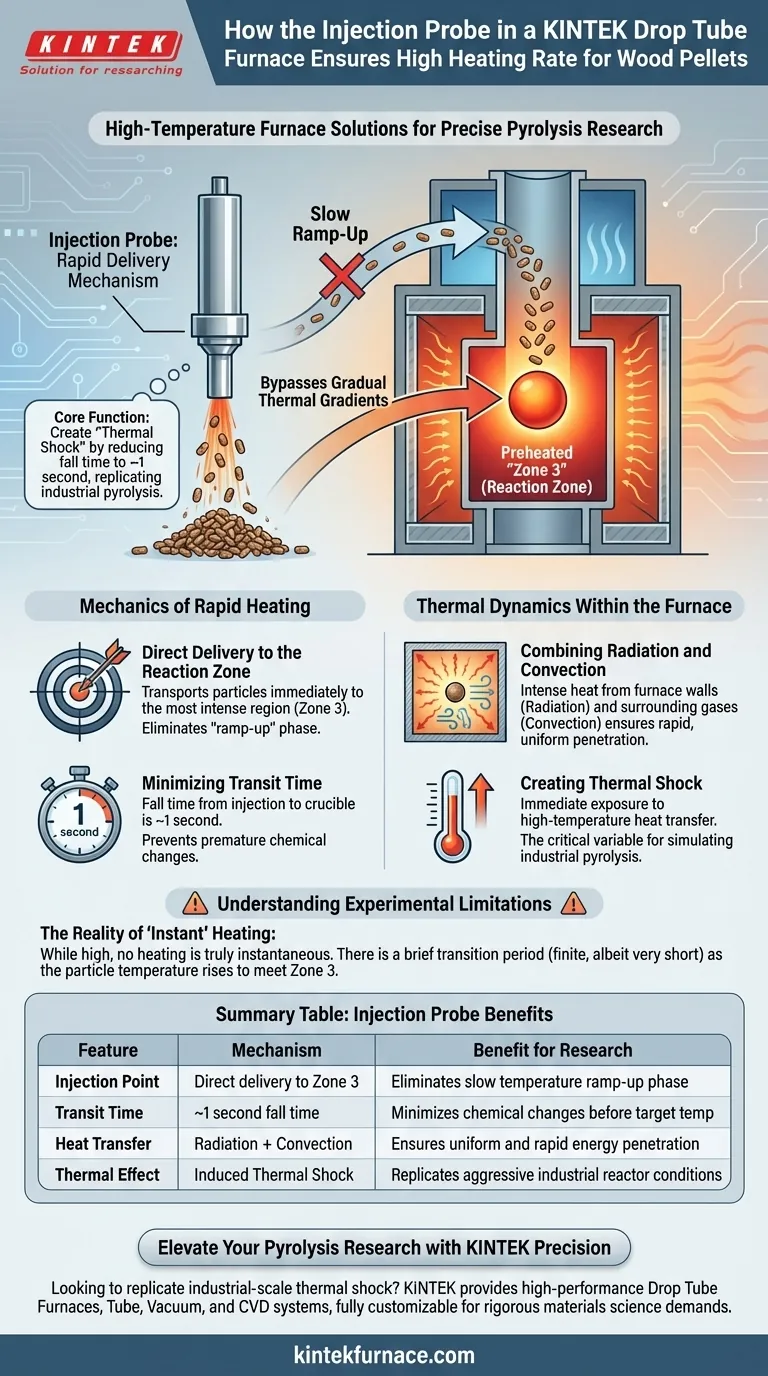

The injection probe functions as a rapid delivery mechanism that bypasses the gradual thermal gradients typically found in static furnace setups. By introducing wood pellets directly from the top of the furnace into a preheated "Zone 3," the probe ensures the material is exposed to peak temperatures almost instantly, rather than warming up slowly as it enters the unit.

The core function of the injection probe is to create "thermal shock" by reducing the particle's fall time to approximately one second. This replicates the aggressive heating conditions of industrial pyrolysis, which cannot be simulated by slowly introducing fuel into a hot zone.

The Mechanics of Rapid Heating

Direct Delivery to the Reaction Zone

The injection probe is designed to transport particles immediately to the most intense region of the furnace.

Rather than allowing the wood pellets to travel through cooler entry zones, the probe delivers them directly into Zone 3, the preheated high-temperature reaction zone. This precise positioning eliminates the "ramp-up" phase that often skews experimental data in standard reactors.

Minimizing Transit Time

To achieve a high heating rate, the duration of the particle's exposure to intermediate temperatures must be negligible.

The design facilitates a fall time from the injection point to the crucible of approximately 1 second. This extremely short transit window prevents the pellet from undergoing significant chemical changes before it reaches the target reaction temperature.

Thermal Dynamics Within the Furnace

Combining Radiation and Convection

Once the probe releases the pellet into the reaction zone, the furnace utilizes two heat transfer modes simultaneously.

The particles are subjected to intense radiation from the furnace walls and convection from the surrounding gases. This dual-action heating ensures the thermal energy penetrates the wood pellet rapidly and uniformly.

Creating Thermal Shock

The combination of rapid positioning and immediate exposure to high-temperature heat transfer results in thermal shock.

This is the critical variable for valid experimentation. It effectively simulates the actual pyrolysis environment found in large-scale industrial furnaces, where fuel is injected directly into massive fireballs or fluidized beds.

Understanding Experimental Limitations

The Reality of "Instant" Heating

While the injection probe creates a high heating rate, it is important to recognize that no heating is truly instantaneous.

Even with a 1-second fall time, there is a brief transition period. Researchers must acknowledge that while this setup closely mimics industrial shock, there is still a finite (albeit very short) period where the particle temperature rises to meet the ambient temperature of Zone 3.

Making the Right Choice for Your Research

When evaluating if a Drop Tube Furnace with an injection probe is suitable for your work, consider your specific experimental goals.

- If your primary focus is simulating industrial pyrolysis: The injection probe is essential because it replicates the thermal shock and rapid decomposition found in commercial reactors.

- If your primary focus is slow combustion or torrefaction: This setup may be too aggressive, as the high heating rate bypasses the gradual drying and warming phases relevant to those processes.

The injection probe effectively acts as a kinetic switch, allowing you to bypass thermal inertia and capture the physics of high-energy reactions.

Summary Table:

| Feature | Mechanism | Benefit for Research |

|---|---|---|

| Injection Point | Direct delivery to Zone 3 | Eliminates the slow temperature ramp-up phase |

| Transit Time | ~1 second fall time | Minimizes chemical changes before target temp |

| Heat Transfer | Radiation + Convection | Ensures uniform and rapid energy penetration |

| Thermal Effect | Induced Thermal Shock | Replicates aggressive industrial reactor conditions |

Elevate Your Pyrolysis Research with KINTEK Precision

Are you looking to replicate industrial-scale thermal shock in a laboratory environment? KINTEK provides high-performance Drop Tube Furnaces, Tube, Vacuum, and CVD systems designed to meet the rigorous demands of modern material science.

Backed by expert R&D and manufacturing, our high-temperature furnaces are fully customizable to your unique research needs, ensuring your wood pellet or fuel analysis is precise and scalable. Contact KINTEK today to discuss how our specialized injection probes and customizable furnace solutions can accelerate your experimental breakthroughs.

Visual Guide

References

- Guillaume Gerandi, Valérie Tschamber. Particulate and gaseous emissions during combustion of wood pellets under low and high heating rates in a drop tube furnace. DOI: 10.2139/ssrn.5600417

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is thermal uniformity important in a drop tube furnace? Ensure Reliable Results and Consistent Processes

- How does a fixed-bed reactor system simulate complex flue gas environments? Optimize Mercury Adsorption Testing

- What technical conditions does a vacuum tube furnace provide for carbon xerogel? Master High-Performance Carbonization

- What is the future potential of fluidized bed vertical tube furnaces? Unlock Efficiency and Growth in Your Industry

- What core functions does an argon atmosphere tube furnace perform? Optimize Al-PTFE FGM Sintering

- What is the core role of a tube furnace in synthesizing magnetic carbon-based composites? Expert Insights

- What are the technical advantages of using an oscillating tube furnace for tellurium dioxide recovery?

- How does the cooling rate of a high-temp tube furnace affect Cu-Zn disordered CZTS layers? Unlock Precise Cation Control