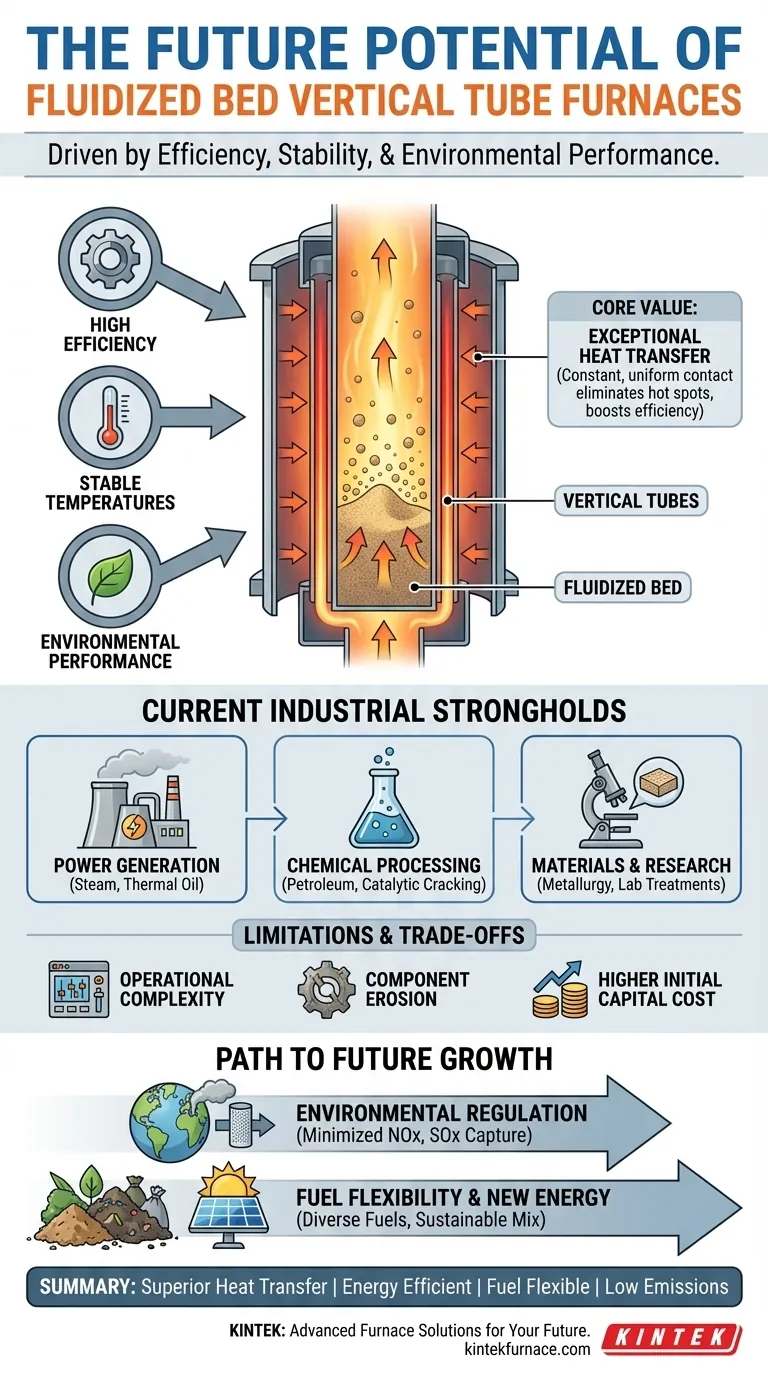

The future potential of fluidized bed vertical tube furnaces is significant, driven by their inherent energy efficiency, high stability, and strong environmental performance. These furnaces are not just an incremental improvement; they represent a foundational technology poised for wider adoption across traditional industries and expansion into the new energy sector as regulations tighten and efficiency demands grow.

The core value of fluidized bed vertical tube furnaces lies in their exceptional heat transfer capabilities. This single principle is the engine behind their energy efficiency, fuel flexibility, and environmental advantages, making them a strategic choice for future industrial heating applications.

How the Technology Creates Value

A fluidized bed furnace works by suspending solid particles, such as sand or a catalyst, on an upward-flowing stream of gas. This creates a "fluidized" mixture that behaves like a liquid, enabling extremely uniform temperatures and rapid heat transfer to the vertical tubes running through the bed.

The Foundation: Superior Heat Transfer

The "fluid-like" behavior of the solid particles ensures that every surface of the internal tubes is in constant, uniform contact with the heat source.

This eliminates hot spots common in other furnace types, leading to higher efficiency and more precise process control.

The Result: High Stability and Efficiency

The immense thermal mass of the fluidized bed acts as a buffer, providing exceptionally stable operating temperatures even with fluctuations in fuel input.

This stability, combined with rapid heat transfer, means less energy is wasted, directly translating to lower fuel consumption and operating costs.

Current Industrial Strongholds

These furnaces are already proven and widely deployed in several critical industrial sectors, forming the basis for their future growth.

Power Generation and Utilities

Fluidized bed furnaces are a cornerstone of modern power generation, particularly in coal-fired power plants.

They are used for generating high-pressure steam to drive turbines and for heating thermal oils (heat medium heating) used in various plant processes.

Chemical and Petrochemical Processing

In the chemical industry, these furnaces are vital for processes requiring precise temperature control, such as petroleum heating and catalytic cracking.

The uniform heating prevents unwanted side reactions and maximizes the yield of valuable products.

Materials and Advanced Research

The technology is also applied in metallurgy and building materials for heating and processing raw materials.

In laboratory settings, these furnaces enable high-temperature material treatments like annealing and quenching, allowing researchers to study material properties under controlled atmospheric conditions.

Understanding the Trade-offs and Limitations

While powerful, this technology is not a universal solution. Understanding its limitations is key to making an informed decision.

Operational Complexity

Fluidized bed systems are more hydrodynamically complex than simple fired heaters. They require more sophisticated control systems and more skilled operators to manage fluidization velocity and bed density.

Component Erosion

The constant motion of abrasive bed particles can cause erosion on the surfaces of the internal tubes and other components over time. This necessitates careful material selection and planned maintenance cycles.

Higher Initial Capital Cost

The complexity of the system, including the need for blowers, particle handling systems, and advanced controls, often results in a higher initial capital investment compared to simpler furnace designs.

The Path to Future Growth

The future potential is not just in expanding current applications, but in adapting the technology to solve emerging challenges.

Driving Force 1: Environmental Regulation

The excellent mixing and controlled combustion temperature in a fluidized bed naturally minimize the formation of pollutants like nitrogen oxides (NOx). Sorbents like limestone can also be added directly to the bed to capture sulfur dioxide (SOx), making it a key technology for meeting strict environmental regulations.

Driving Force 2: Fuel Flexibility and New Energy

Fluidized beds are uniquely capable of burning a wide variety of fuels, including low-grade coal, biomass, industrial waste, and other opportunity fuels. This fuel flexibility is critical as industries move toward a more sustainable and diverse energy mix, positioning the technology for a role in the new energy sector.

How to Apply This to Your Project

Your decision to adopt this technology should be based on your primary strategic goal.

- If your primary focus is maximizing operational efficiency and reducing fuel costs: The superior heat transfer and thermal stability of a fluidized bed furnace offer a clear and compelling advantage.

- If your primary focus is meeting environmental targets or achieving fuel flexibility: This technology provides an integrated solution for emissions control and the ability to utilize low-cost or sustainable fuels.

- If your primary focus is advanced materials research or process development: The precise temperature and atmospheric control make it an invaluable tool for laboratory and pilot-scale applications.

Ultimately, the adaptability of the fluidized bed vertical tube furnace makes it a durable and forward-looking choice for demanding industrial heating applications.

Summary Table:

| Aspect | Key Details |

|---|---|

| Core Advantages | Superior heat transfer, energy efficiency, high stability, fuel flexibility, low emissions |

| Current Applications | Power generation (steam, heat medium heating), chemical processing (petroleum heating, catalytic cracking), materials research (annealing, quenching) |

| Future Drivers | Tightening environmental regulations, expansion into new energy sectors, demand for fuel flexibility |

| Limitations | Higher initial cost, operational complexity, component erosion from abrasive particles |

Ready to harness the power of fluidized bed technology for your projects? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and industrial requirements. Whether you're in power generation, chemical processing, or new energy sectors, we can help you achieve superior efficiency and environmental performance. Contact us today to discuss how our solutions can drive your success!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision