The oscillating tube furnace distinguishes itself through a unique dynamic mixing mechanism that optimizes the reaction between tellurium dioxide and hydrogen. By utilizing large-angle reciprocating movements—specifically up to 314 degrees—this equipment maximizes the contact surface area between the solid powder and the gas. This technical advantage directly translates to superior heat transfer efficiency and a higher degree of reaction uniformity compared to standard methods.

Core Takeaway The oscillating tube furnace is not just a heating vessel; it is a kinetic simulator. By mechanically enforcing thorough gas-solid contact through reciprocating motion, it replicates the efficiency of industrial-scale processing while maintaining the precision required for high-purity recovery.

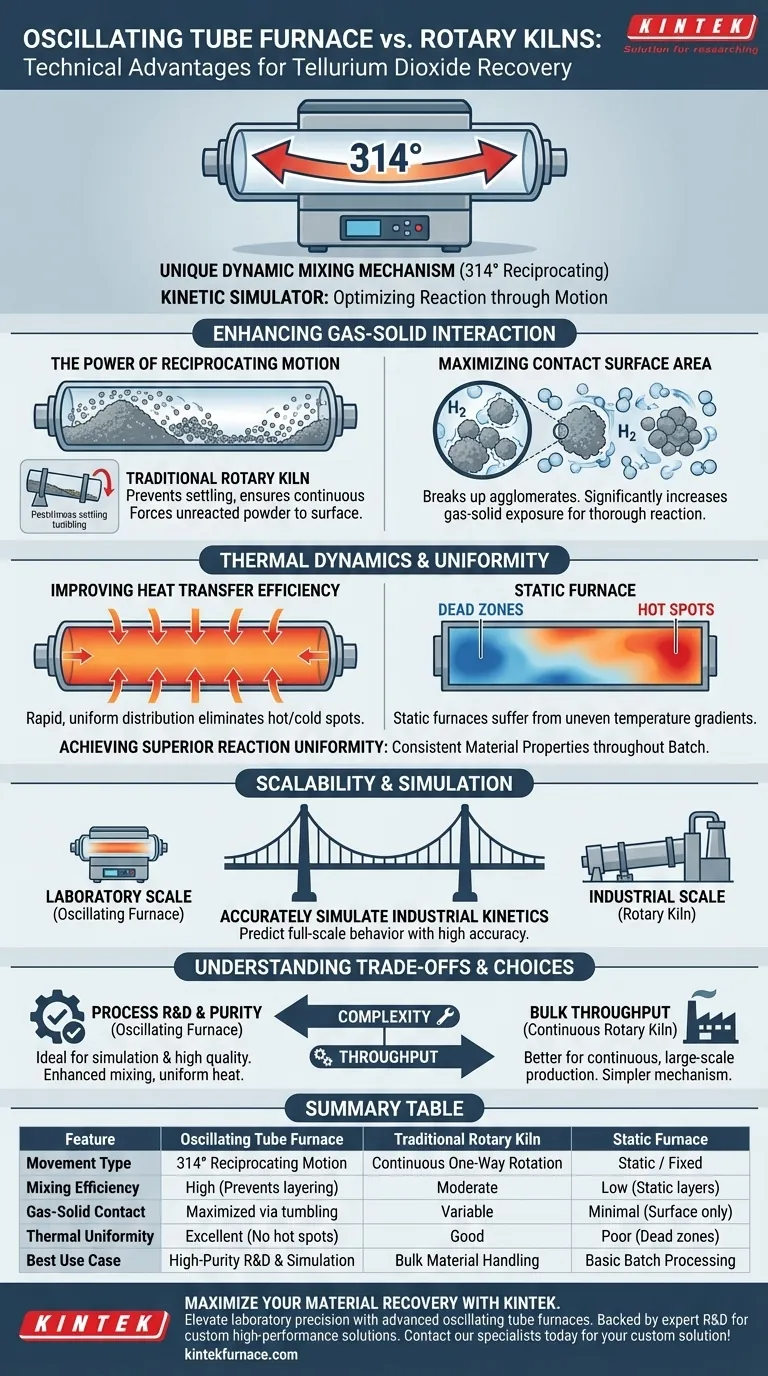

Enhancing Gas-Solid Interaction

The Power of Reciprocating Motion

Standard rotary kilns typically rotate continuously in one direction. In contrast, the oscillating tube furnace employs a reciprocating movement, rotating back and forth up to 314 degrees.

This specific motion prevents the tellurium dioxide powder from settling into static layers. It forces the material to tumble and cascade repeatedly, ensuring that unreacted powder is constantly brought to the surface.

Maximizing Contact Surface Area

Recovery efficiency relies heavily on how well the reactive hydrogen gas contacts the solid tellurium dioxide. The oscillating action significantly increases the effective contact surface area exposed to the gas stream.

By breaking up agglomerates and constantly refreshing the surface of the powder bed, the furnace ensures the reduction reaction occurs thoroughly throughout the entire batch, not just at the top layer.

Thermal Dynamics and Uniformity

Improving Heat Transfer Efficiency

Static furnaces often suffer from heat accumulation or "dead zones" where temperature gradients vary. The dynamic mixing of the oscillating furnace facilitates rapid and uniform heat distribution.

As the powder moves, it absorbs heat more evenly from the tube walls and the gas environment. This eliminates hot spots that could degrade the material and cold spots that result in incomplete reactions.

Achieving Superior Reaction Uniformity

Uniformity is the ultimate goal in tellurium dioxide recovery. The combination of consistent heat and maximized gas exposure ensures the properties of the processed material are consistent throughout the batch.

This reduces the risk of variability in the final product, a common issue in static mesh belt or push plate furnaces where air leakage and uneven heating occur.

Scalability and Simulation

Bridging Laboratory and Industry

A critical advantage of the oscillating tube furnace is its ability to simulate industrial kinetics at a laboratory scale.

It replicates the mixing dynamics and heat transfer profiles of massive industrial rotary kilns. This allows engineers to predict how the recovery process will behave in a full-scale production environment with high accuracy.

Understanding the Trade-offs

Complexity vs. Throughput

While the oscillating mechanism offers superior mixing, it introduces mechanical complexity compared to simple static furnaces. The moving parts require maintenance to ensure the 314-degree motion remains precise.

Furthermore, while excellent for batch processing and high-precision recovery, an oscillating setup may have lower throughput capabilities compared to a continuous, industrial-scale rotary kiln designed for bulk material handling.

Making the Right Choice for Your Goal

To determine if an oscillating tube furnace is the right fit for your tellurium dioxide recovery process, consider your specific objectives:

- If your primary focus is Process R&D: The oscillating furnace is ideal because it accurately simulates industrial rotary kiln kinetics, allowing you to refine parameters with confidence before scaling up.

- If your primary focus is Product Purity: The enhanced mixing and uniform heat transfer make this the superior choice for ensuring high-quality, consistent material properties.

The oscillating tube furnace transforms the recovery process from a passive heating event into a dynamic, highly controlled reaction environment.

Summary Table:

| Feature | Oscillating Tube Furnace | Traditional Rotary Kiln | Static Furnace |

|---|---|---|---|

| Movement Type | 314° Reciprocating Motion | Continuous One-Way Rotation | Static / Fixed |

| Mixing Efficiency | High (Prevents layering) | Moderate | Low (Static layers) |

| Gas-Solid Contact | Maximized via tumbling | Variable | Minimal (Surface only) |

| Thermal Uniformity | Excellent (No hot spots) | Good | Poor (Dead zones) |

| Best Use Case | High-Purity R&D & Simulation | Bulk Material Handling | Basic Batch Processing |

Maximize Your Material Recovery with KINTEK

Elevate your laboratory precision with KINTEK’s advanced oscillating tube furnaces. Backed by expert R&D and world-class manufacturing, we provide high-performance thermal solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique processing requirements. Whether you are refining tellurium dioxide recovery or simulating industrial kinetics, our equipment ensures superior uniformity and efficiency.

Ready to optimize your high-temperature processes?

Contact our specialists today to find your custom solution!

Visual Guide

References

- Hanwen Chung, Bernd Friedrich. Hydrogen Reduction of Tellurium Oxide in a Rotary Kiln, Initial Approaches for a Sustainable Process. DOI: 10.3390/cryst15050478

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What critical process conditions does a tube furnace provide for V-NbOPO4@rGO? Ensure Superior Composite Synthesis

- Why is a laboratory tube furnace considered essential for fabricating carbonized lignin nanofiber electrodes?

- What are the differences between solid tube and split type tube furnaces? Choose the Right Furnace for Your Lab

- What are some common applications of split tube furnaces? Unlock Easy Sample Access for Your Lab

- Why is the integration of an axial rotation mechanism significant in tube furnaces? Enhance Experimental Control

- What is the technical significance of phased high-temperature annealing in a tube furnace for 3D Porous Graphene?

- Why is biochar mixed with KOH and treated at 800 °C in a tubular furnace? Unlock Hierarchical Porous Carbon Secrets

- What are the typical working temperature ranges for lab tube furnaces? Find the Right Furnace for Your Process