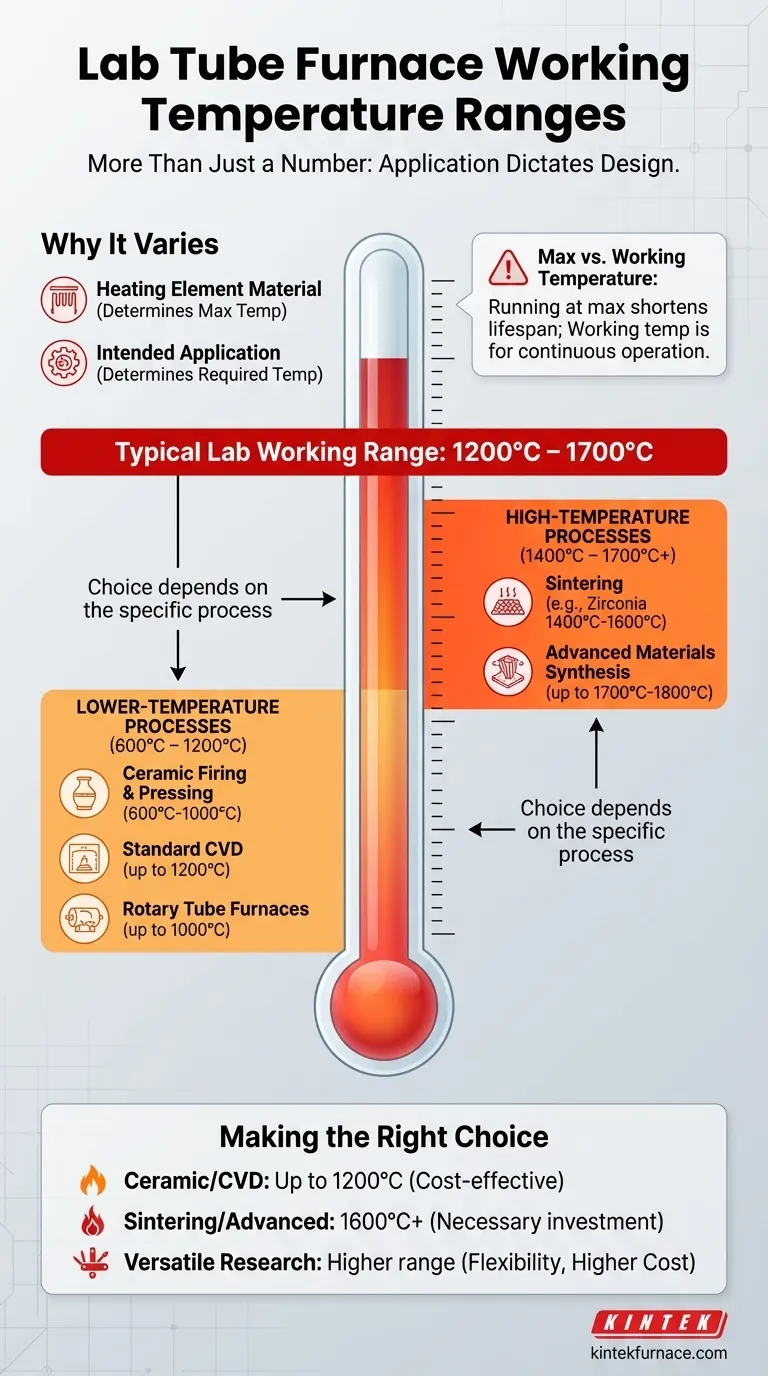

In short, a typical lab tube furnace operates at a working temperature between 1200°C and 1700°C. However, this range is highly dependent on the furnace's specific design, heating elements, and most importantly, its intended application. Many specialized tube furnaces operate well below this range for specific material processing tasks.

The question is not simply "how hot can it get?" but rather "which furnace is engineered for my specific thermal process?" The furnace's temperature range is a direct consequence of its intended application, from lower-temperature ceramic firing to high-temperature material sintering.

Why "Tube Furnace" Describes a Goal, Not a Single Temperature

The term "tube furnace" is broad. The specific temperature capabilities are dictated by the physical limits of its components and the requirements of the scientific process it was built for.

The Critical Role of the Heating Element

The heart of any furnace is its heating element, and the material used for this element is the primary factor determining its maximum temperature.

Different materials are used for different temperature regimes. For instance, elements designed for 1200°C applications are fundamentally different from those engineered to withstand 1700°C or more for sustained periods.

Application Dictates Design

A furnace is a tool designed for a specific job. The required temperature for a given chemical or physical process determines the type of furnace needed.

You don't use a high-temperature sintering furnace for a low-temperature pressing application, as it would be inefficient and unnecessarily expensive.

Common Temperature Ranges by Application

To select the right instrument, it is more useful to think in terms of the process you need to perform. The required temperature for that process will guide you to the correct class of furnace.

Lower-Temperature Processes (600°C – 1200°C)

This range covers many common thermal processing applications, particularly for ceramics and certain types of chemical vapor deposition (CVD).

- Ceramic Firing & Pressing: These processes typically operate from 600°C to 1000°C. Pressing furnaces for specific ceramics may fall between 700°C and 900°C.

- Standard CVD: Many standard CVD processes require stable thermal conditions up to 1200°C.

- Rotary Tube Furnaces: Used for continuous processing of powders and granulates, these often operate up to 1000°C.

High-Temperature Processes (1400°C – 1700°C+)

This category is reserved for processing advanced materials that require extreme heat to achieve the desired material properties.

- Sintering: The process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. Sintering zirconia, for example, requires temperatures between 1400°C and 1600°C.

- Advanced Materials Synthesis: Research into new alloys or ceramics may push the limits, requiring furnaces that can reliably operate at 1700°C or even 1800°C, similar to high-end muffle furnaces.

Understanding the Trade-offs: Maximum vs. Working Temperature

One of the most common mistakes is conflating a furnace's advertised maximum temperature with its reliable, continuous working temperature. They are not the same.

The Risk of Running at Maximum

A furnace's maximum temperature is often a peak rating that should only be reached for very short durations.

Consistently operating a furnace at its absolute maximum will drastically shorten the lifespan of its heating elements and other critical components, leading to premature failure and costly repairs. The working temperature is a lower, more sustainable rating for continuous, reliable operation.

Atmosphere and Stability

The atmosphere inside the process tube (e.g., air, vacuum, inert gas like argon) can also impact performance. Some heating elements degrade faster in certain atmospheres, and achieving a stable, uniform temperature profile can be more challenging under vacuum.

Making the Right Choice for Your Process

Base your selection on the specific, repeatable needs of your work.

- If your primary focus is ceramic firing or standard CVD: A furnace with a reliable working temperature up to 1200°C is a suitable and cost-effective choice.

- If your primary focus is sintering zirconia or other advanced ceramics: You must invest in a high-temperature furnace capable of sustained operation at 1600°C or higher.

- If your primary focus is versatile research with unknown future needs: Selecting a furnace with a higher range (e.g., 1700°C) provides flexibility, but be prepared for a higher initial cost and potentially higher running costs.

Ultimately, choosing the right furnace begins with a clear understanding of the temperature requirements of your material and process.

Summary Table:

| Application | Typical Temperature Range | Key Uses |

|---|---|---|

| Lower-Temperature Processes | 600°C – 1200°C | Ceramic firing, standard CVD, rotary tube processing |

| High-Temperature Processes | 1400°C – 1700°C+ | Sintering zirconia, advanced materials synthesis |

| General Working Range | 1200°C – 1700°C | Common lab operations, varies by design and elements |

Need a high-temperature furnace tailored to your lab's unique needs? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your experimental requirements—whether for sintering, CVD, or other thermal processes. Contact us today to discuss how our furnaces can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide