The integration of an axial rotation mechanism fundamentally transforms a tube furnace from a static heating device into a dynamic experimental platform. By allowing the furnace to be positioned at precise angles—including vertically upward, vertically downward, horizontal, or specific inclinations—this mechanism gives researchers direct control over how gravity and physical orientation influence the thermal process.

The core value of an axial rotation mechanism lies in its ability to simulate diverse environmental conditions; it enables the study of gravity-driven processes and enhances gas-solid mixing kinetics in ways that fixed-geometry furnaces cannot.

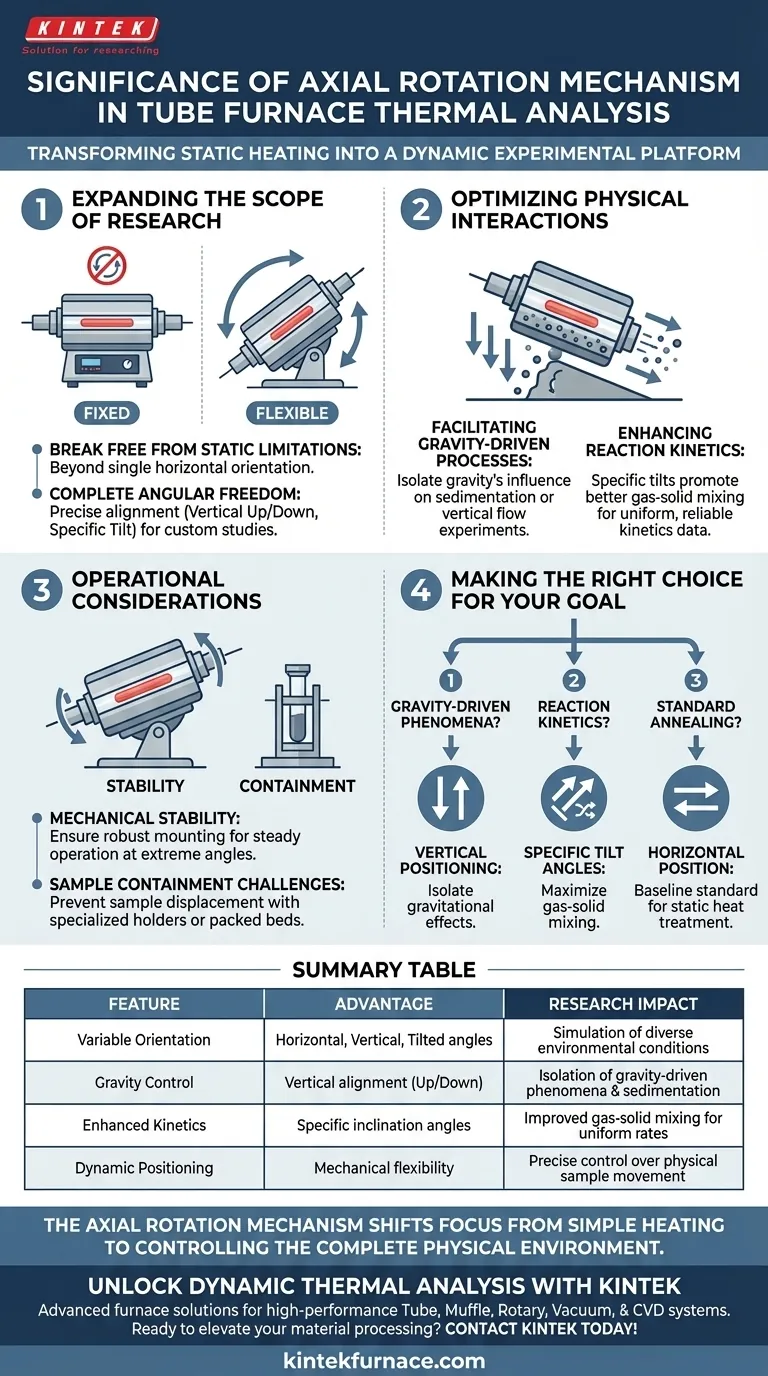

Expanding the Scope of Research

Breaking Free from Static Limitations

Standard tube furnaces typically lock researchers into a single, horizontal orientation.

An axial rotation mechanism removes this constraint. It provides the mechanical flexibility to align the heating zone with the specific physical requirements of the experiment.

Complete Angular Freedom

The mechanism allows for a full range of positioning.

You can configure the furnace for vertical upward or downward alignment for specific flow studies. Alternatively, you can set precise tilt angles to induce movement within the sample tube.

Optimizing Physical Interactions

Facilitating Gravity-Driven Processes

Many thermal processes are heavily influenced by gravity.

By positioning the furnace vertically, researchers can study phenomena where gravity acts as a primary driver, such as specific sedimentation or vertical flow experiments. This allows for the isolation of gravity as a variable in the thermal analysis.

Enhancing Reaction Kinetics

For experiments involving gas-solid interactions, static positioning often leads to poor contact between reactants.

Using a specific inclination or tilt angle promotes better gas-solid mixing. This movement ensures that reactive gases (controlled by devices like rotameters) interact more uniformly with the solid sample, leading to more reliable kinetics data.

Operational Considerations

Understanding Mechanical Stability

While versatile, rotating a furnace changes the mechanical stresses on the system.

Users must ensure that the mounting and locking mechanisms are robust enough to hold the furnace steady at extreme angles, particularly vertical ones.

Sample Containment Challenges

Changing the angle of the furnace inherently changes the behavior of the sample.

When moving from horizontal to vertical or tilted positions, standard crucibles or boats may slip. Specialized sample holders or packed bed configurations are often required to prevent sample displacement during the experiment.

Making the Right Choice for Your Goal

To maximize the utility of an axial rotation mechanism, align the furnace orientation with your specific research objective:

- If your primary focus is gravity-driven phenomena: distinct vertical positioning (upward or downward) is essential to isolate gravitational effects on the process.

- If your primary focus is reaction kinetics: Use specific tilt angles to induce movement and maximize gas-solid mixing for uniform reaction rates.

- If your primary focus is standard annealing: A horizontal position remains the baseline standard for static heat treatment.

Ultimately, the axial rotation mechanism shifts the focus from simple heating to controlling the complete physical environment of your reaction.

Summary Table:

| Feature | Advantage | Research Impact |

|---|---|---|

| Variable Orientation | Horizontal, Vertical, or Tilted angles | Simulation of diverse environmental conditions |

| Gravity Control | Vertical alignment (Up/Down) | Isolation of gravity-driven phenomena and sedimentation |

| Enhanced Kinetics | Specific inclination angles | Improved gas-solid mixing for uniform reaction rates |

| Dynamic Positioning | Mechanical flexibility | Precise control over physical sample movement |

Unlock Dynamic Thermal Analysis with KINTEK

Take your thermal research beyond static limitations. KINTEK’s advanced furnace solutions—backed by expert R&D and precision manufacturing—offer high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed for your most demanding applications. Whether you require standard configurations or customizable systems with integrated axial rotation to optimize reaction kinetics and gravity-driven studies, our team provides the technical expertise to tailor the perfect solution for your lab.

Ready to elevate your material processing? Contact KINTEK today to discuss your unique needs!

Visual Guide

References

- Beata Brzychczyk, L. J. Sikora. Modernization of a Tube Furnace as Part of Zero-Waste Practice. DOI: 10.3390/su17198940

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How do advanced control systems enhance the operation of a tube furnace? Boost Precision and Efficiency in Thermal Processing

- How does a fast Joule-heating device differ from a tubular furnace? Kinetic vs. Thermodynamic Control

- How can tube furnaces be scaled for large-scale production? Boost Throughput with Modular Systems

- How is a laboratory tube furnace used in materials science research? Unlock Precision in Material Synthesis and Heat Treatment

- What is the function of a cylindrical furnace during the pre-carbonization of Hanji? Expert Thermal Processing Tips

- What role does a vacuum tube furnace play as a reactor during the coal gasification reaction stage?

- What critical process conditions does a tube furnace provide for V-NbOPO4@rGO? Ensure Superior Composite Synthesis

- What role does a high-temperature tube furnace play in converting polymer precursors? Precision Synthesis Guide