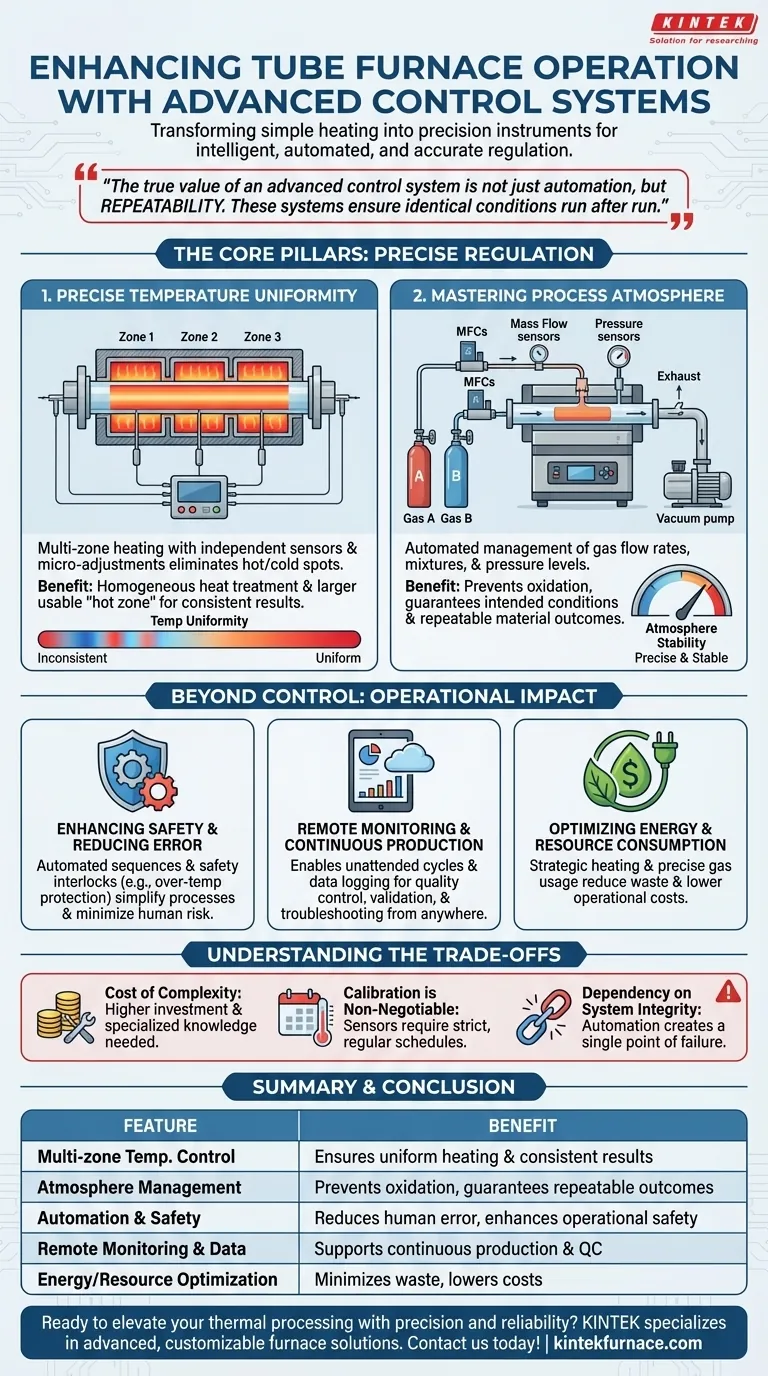

At their core, advanced control systems transform a tube furnace from a simple heating element into a precision instrument. They do this by enabling intelligent, automated, and highly accurate regulation of both temperature and internal atmosphere, which simplifies operation, reduces human error, enhances safety, and ensures the process results are consistent and repeatable.

The true value of an advanced control system is not just automation, but repeatability. These systems ensure that the conditions inside the furnace are identical run after run, which is the cornerstone of reliable material processing, research, and industrial production.

The Core Pillars of Advanced Furnace Control

Advanced systems fundamentally improve furnace operation by providing granular control over the two most critical process variables: temperature and atmosphere.

Achieving Precise Temperature Uniformity

For most applications, simply being "hot" is not enough; the temperature must be correct and consistent across the entire sample.

Advanced controls use multi-zone heating, where the furnace tube is surrounded by several independent heating elements. A sophisticated controller monitors each zone with its own sensor, making micro-adjustments to eliminate hot or cold spots.

This ensures homogeneous heat treatment, which is vital for applications requiring a uniform thermal profile, such as crystal growth or annealing long components. The result is superior consistency and a much larger usable "hot zone."

Mastering the Process Atmosphere

Many modern material processes must occur in a specific gaseous environment, whether inert, reactive, or a vacuum.

Atmosphere control systems use mass flow controllers and pressure sensors to precisely manage the gas flow rates, mixtures, and pressure levels inside the tube. The system continuously monitors and adjusts these parameters to maintain a highly stable environment.

This precision prevents unwanted chemical reactions (like oxidation) and guarantees that the material is treated under the exact intended conditions, ensuring repeatable material outcomes.

Beyond Control: The Impact on Operations

The benefits of precise regulation extend beyond the process itself, creating a safer, more efficient, and more productive operational environment.

Enhancing Safety and Reducing Human Error

By automating complex heating, cooling, and gas purge sequences, control systems simplify the process for operators. This drastically reduces the potential for human error that could otherwise ruin a sample or create a safety hazard.

These systems also include programmed safety interlocks, such as over-temperature protection and automated shutdown procedures, that function far more reliably than manual oversight.

Enabling Remote Monitoring and Continuous Production

For industrial settings, the ability to monitor and control furnace operations remotely is a significant advantage. This supports continuous, unattended production cycles, freeing up personnel and allowing for rapid response to any alerts or deviations.

Data logging features also provide a complete record of every process run, which is invaluable for quality control, process validation, and troubleshooting.

Optimizing Energy and Resource Consumption

An intelligent controller is an efficient one. By understanding the thermal dynamics of the furnace, it can apply heat more strategically, avoiding overshoot and minimizing energy waste during ramps and soaks.

Similarly, precise control over gas flow ensures that expensive process gases are used effectively, preventing the waste associated with less accurate manual systems.

Understanding the Trade-offs

While powerful, advanced control systems introduce their own set of considerations that must be managed.

The Cost of Complexity

These systems represent a higher upfront investment compared to basic furnaces. Their complexity may also require more specialized knowledge for initial setup, programming, and maintenance.

Calibration is Non-Negotiable

An advanced control system is only as accurate as its sensors. Thermocouples and pressure sensors can drift over time and require a strict, regular calibration schedule. Without it, the system's precision is meaningless.

Dependency on System Integrity

While automation reduces human error, it also creates a single point of failure. A malfunction in the central controller or a key sensor can bring the entire operation to a halt, whereas a simpler manual system might offer more rudimentary workarounds.

Making the Right Choice for Your Goal

To select the right level of control, you must align the furnace's capabilities with your primary objective.

- If your primary focus is maximum repeatability for research or quality control: Prioritize a system with multi-zone temperature control and fully integrated atmosphere management.

- If your primary focus is high-throughput industrial production: Emphasize automation features, robust safety interlocks, and remote monitoring and data logging capabilities.

- If your primary focus is process development and flexibility: Choose a system with a highly programmable controller that allows you to easily create, save, and execute a wide variety of thermal and atmospheric profiles.

Ultimately, investing in an advanced control system is about moving from basic heating to predictable, data-driven thermal processing.

Summary Table:

| Feature | Benefit |

|---|---|

| Multi-zone temperature control | Ensures uniform heating and consistent results |

| Atmosphere management | Prevents oxidation and guarantees repeatable outcomes |

| Automation and safety interlocks | Reduces human error and enhances operational safety |

| Remote monitoring and data logging | Supports continuous production and quality control |

| Energy and resource optimization | Minimizes waste and lowers operational costs |

Ready to elevate your thermal processing with precision and reliability? KINTEK specializes in advanced high-temperature furnace solutions, including Tube Furnaces, Muffle Furnaces, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability