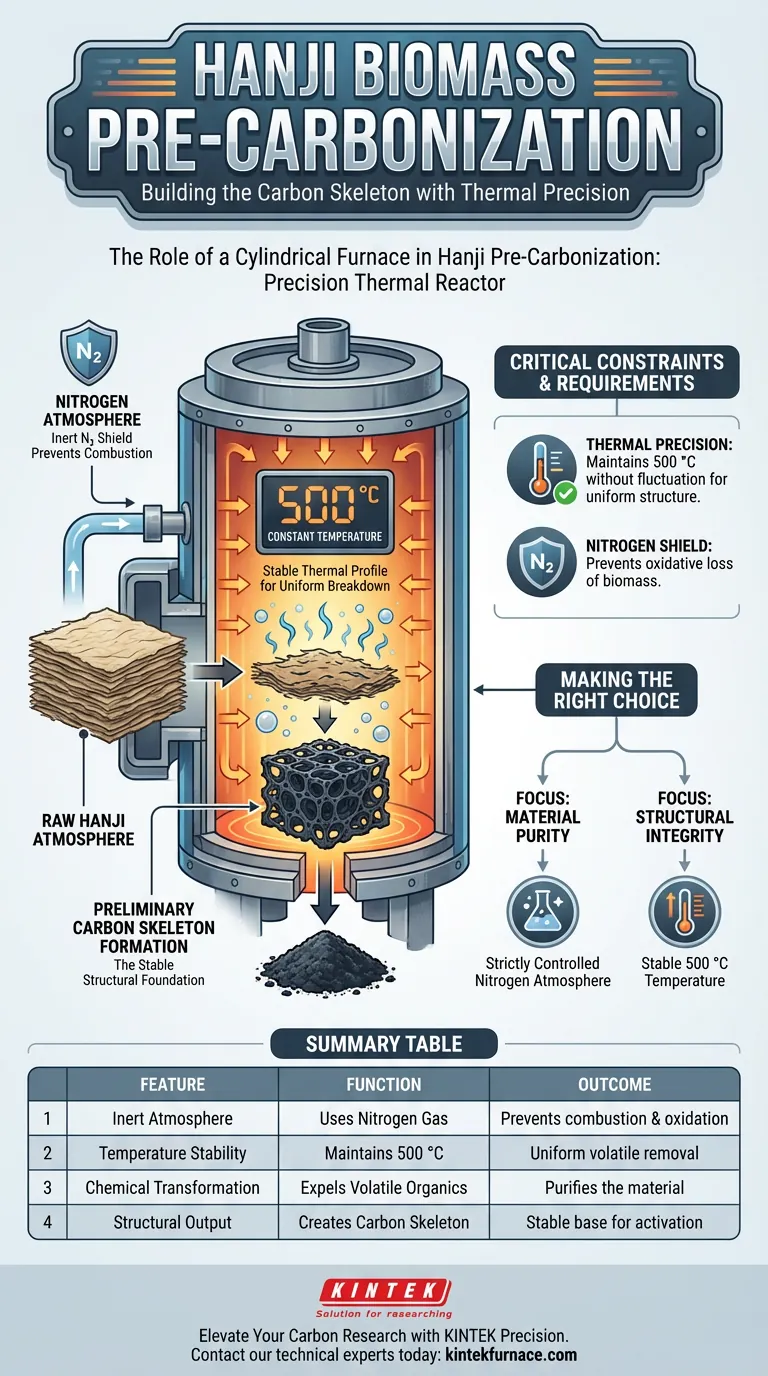

The cylindrical furnace serves as a precision-controlled thermal reactor. It facilitates the pre-carbonization of Hanji by maintaining a specific nitrogen atmosphere and a constant temperature of 500 °C. This environment allows the biomass to undergo essential chemical changes without combusting.

The furnace’s primary role is to convert raw Hanji into a stable preliminary carbon skeleton. By removing volatile components in a controlled 500 °C nitrogen environment, it establishes the necessary structural foundation for subsequent activation stages.

The Mechanics of Pre-Carbonization

Establishing a Controlled Atmosphere

The furnace creates a specialized environment by introducing nitrogen gas. This ensures the Hanji is treated in an inert atmosphere rather than normal air.

This control is critical because it prevents the biomass from burning up, which would occur if oxygen were present at high temperatures.

Thermal Stabilization

The equipment is designed to hold a stable constant temperature of 500 °C.

Maintaining this specific temperature profile is required to initiate the breakdown of the biomass material uniformly.

Material Transformation

Removal of Volatile Components

As the Hanji sits within the furnace at 500 °C, the heat drives off volatile organic compounds.

These non-carbon elements are expelled from the material, effectively purifying the structure.

Formation of the Carbon Skeleton

Once the volatiles are removed, the remaining material forms a preliminary carbon skeleton.

This skeleton retains the physical shape needed for future processing. It serves as the robust baseline required before the material can undergo activation.

Critical Constraints and Requirements

Reliance on Thermal Precision

The success of this process hinges on the furnace's ability to maintain 500 °C without fluctuation.

If the temperature varies significantly, the carbon skeleton may form unevenly, compromising the material's structural integrity.

Necessity of the Nitrogen Shield

The process is entirely dependent on the integrity of the nitrogen atmosphere.

A failure to maintain this inert environment would result in the loss of the biomass through oxidation, rendering the pre-carbonization phase a failure.

Making the Right Choice for Your Goal

To ensure the successful conversion of Hanji into a carbon precursor, consider these operational priorities:

- If your primary focus is Material Purity: Ensure the furnace maintains a strictly controlled nitrogen atmosphere to prevent any oxidative degradation of the biomass.

- If your primary focus is Structural Integrity: Verify the furnace can hold a stable 500 °C temperature to facilitate uniform removal of volatiles and consistent skeleton formation.

The cylindrical furnace is the essential tool that bridges the gap between raw natural biomass and high-performance carbon material.

Summary Table:

| Feature | Function in Hanji Pre-Carbonization |

|---|---|

| Inert Atmosphere | Uses nitrogen gas to prevent biomass combustion and oxidation. |

| Temperature Stability | Maintains a constant 500 °C for uniform volatile removal. |

| Chemical Transformation | Expels volatile organic compounds to purify the material. |

| Structural Output | Creates a stable preliminary carbon skeleton for future activation. |

Elevate Your Carbon Research with KINTEK Precision

Achieving the perfect carbon skeleton requires absolute thermal stability and atmospheric integrity. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique high-temperature processing needs. Whether you are perfecting Hanji pre-carbonization or developing advanced carbon materials, our lab furnaces deliver the uniform heating and inert control you demand.

Ready to optimize your thermal processes? Contact our technical experts today to find the ideal furnace solution for your laboratory.

Visual Guide

References

- Yunju Choi, Heon‐Cheol Shin. Enhancing Li-S Battery Performance with Porous Carbon from Hanji. DOI: 10.3390/batteries11010004

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How does a high-temperature quartz tube reactor facilitate the synthesis of PC-CNT microspheres? Expert Insights

- What environmental applications do rotary tube furnaces have? Transform Waste into Value with Advanced Thermal Processing

- What is the maximum temperature for a tube furnace? Unlock the Right Heat for Your Application

- How is heat transferred to the material inside the tube furnace? Master the Three-Stage Process for Precise Heating

- What experimental conditions does a high-temperature tube furnace provide for V2AlC MAX phase sintering?

- What are the primary uses of tube furnaces in academic and industrial settings? Unlock Precision Thermal Processing

- Why is a tube furnace required for the calcination of TiO2 in an H2/Ar mixed atmosphere? Engineering TiO2-X Defects

- In which fields and for what processes are vertical tube furnaces widely used? Unlock Precision Material Processing