The fundamental difference lies in the thermodynamics of reaction time. While a traditional tubular furnace relies on steady, prolonged heating to reach equilibrium, a fast Joule-heating device utilizes extreme heating rates and millisecond-to-second reaction times to access non-equilibrium states.

Conventional heating methods allow atoms to migrate naturally to the surface, whereas the rapid thermal shock and quenching of Joule heating "freeze" the material's structure instantly. This kinetic control is the only way to effectively confine ruthenium (Ru) single atoms within the subsurface layer of a Ni3FeN lattice.

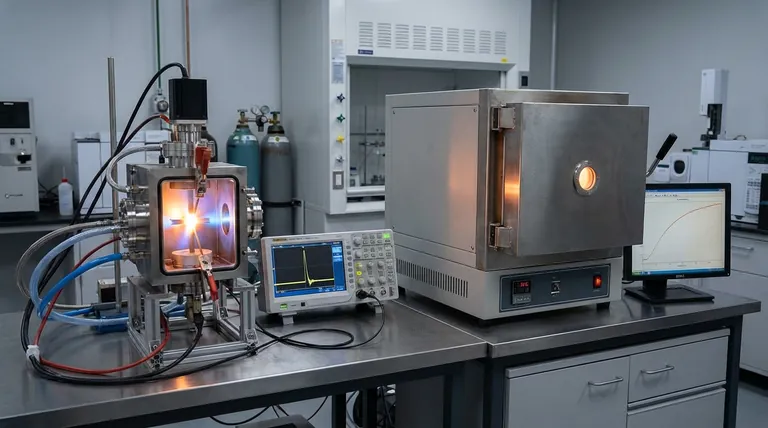

The Mechanics of Thermal Processing

The Limitations of Steady Heating

A traditional tubular furnace operates on the principle of steady-state heating. The material is brought up to temperature gradually and held there for extended periods.

This long-duration exposure allows the material to reach a state of thermodynamic equilibrium. While useful for bulk synthesis, this environment promotes atomic diffusion.

The Advantage of Millisecond Reactions

In contrast, a fast Joule-heating device achieves extremely high heating rates almost instantaneously.

The total reaction time is measured in milliseconds to seconds. This ultra-fast processing creates a unique thermal environment that prevents the material from settling into its most energetically relaxed state.

Controlling Atomic Migration

The Migration Problem

During the synthesis of Ni3FeN lattices, ruthenium (Ru) atoms naturally tend to migrate toward the surface when exposed to heat.

In a standard furnace, the long heating duration provides ample time for this migration to occur. The result is Ru atoms accumulating on the surface rather than remaining buried within the structure.

Trapping the Atoms via Quenching

The Joule-heating process is followed immediately by rapid quenching.

Because the heating cycle is so short and the cooling is so abrupt, the atomic movement is arrested mid-process. This effectively freezes specific metastable structures, trapping the Ru single atoms within the subsurface layer before they can escape to the exterior.

Understanding the Trade-offs

Equilibrium vs. Kinetic Control

The choice between these devices represents a trade-off between thermodynamic stability and kinetic precision.

A tubular furnace is excellent for creating stable, equilibrium phases where atoms sit in their naturally preferred positions. However, it fails when the goal is to create a high-energy, "unnatural" configuration like a buried single atom.

Precision Requires Speed

Joule heating is strictly required when the desired material property relies on a metastable state.

If your synthesis requires atoms to remain in high-energy positions (like the subsurface of a lattice) without relaxing to the surface, the slow ramp rates of traditional furnaces will invariably lead to failure.

Making the Right Choice for Your Goal

To achieve the correct atomic configuration for your material, consider the following regarding thermal processing:

- If your primary focus is subsurface confinement: You must use fast Joule heating to freeze the lattice structure instantly, preventing the natural migration of dopants like Ru to the surface.

- If your primary focus is thermodynamic equilibrium: A traditional tubular furnace is appropriate, as it allows time for atoms to diffuse and settle into their most stable, surface-heavy configurations.

The speed of your thermal process dictates the final location of your atoms.

Summary Table:

| Feature | Fast Joule-Heating Device | Traditional Tubular Furnace |

|---|---|---|

| Heating Rate | Ultra-fast (Millisecond to Second) | Slow, Gradual Ramping |

| Control Mechanism | Kinetic Control (Non-equilibrium) | Thermodynamic Equilibrium |

| Atomic Migration | Minimized; Atoms 'frozen' in place | High; Atoms migrate to stable sites |

| Ru Atom Position | Buried within subsurface lattice | Surface-heavy accumulation |

| Main Advantage | Synthesizes metastable structures | Reliable for bulk stable phases |

Unlock Advanced Atomic Precision with KINTEK

Are you struggling to maintain metastable structures or precise atomic confinement in your research? KINTEK provides the cutting-edge thermal solutions needed to push the boundaries of material science.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to meet the unique heating rates and atmospheric requirements of your specific project. Whether you are synthesizing single-atom catalysts or developing next-generation lattices, our lab high-temperature furnaces deliver the uniformity and control your work demands.

Ready to elevate your synthesis results? Contact KINTEK today to discuss your custom furnace needs!

References

- Yunxiang Lin, Li Song. Optimizing surface active sites via burying single atom into subsurface lattice for boosted methanol electrooxidation. DOI: 10.1038/s41467-024-55615-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How do multi zone tube furnaces contribute to materials science research? Unlock Precise Temperature Control for Advanced Synthesis

- What critical process conditions does a tube atmosphere furnace provide for Sr2CuWO6? Control Atmosphere & Temperature

- Why does a tube sintering furnace require precise control for (RuIr)O2/C catalysts? Optimize Catalyst Performance

- Why must a tube furnace used for the pyrolysis of tungsten-based nanocomposites be equipped with a precision gas flow?

- What is the function of a tube reduction furnace? Enhance Ru@PG Catalysts with Ar/H2 Precision

- What is the primary function of a Drop Tube Furnace in iron ore beneficiation? Unlock High-Precision Thermal Shock.

- What is the primary role of a tube furnace during pre-carbonization? Optimize Biomass-to-Hard-Carbon Conversion

- How do controlled tube furnace systems achieve atmosphere regulation? Study Zirconia Phase Transformation Laws