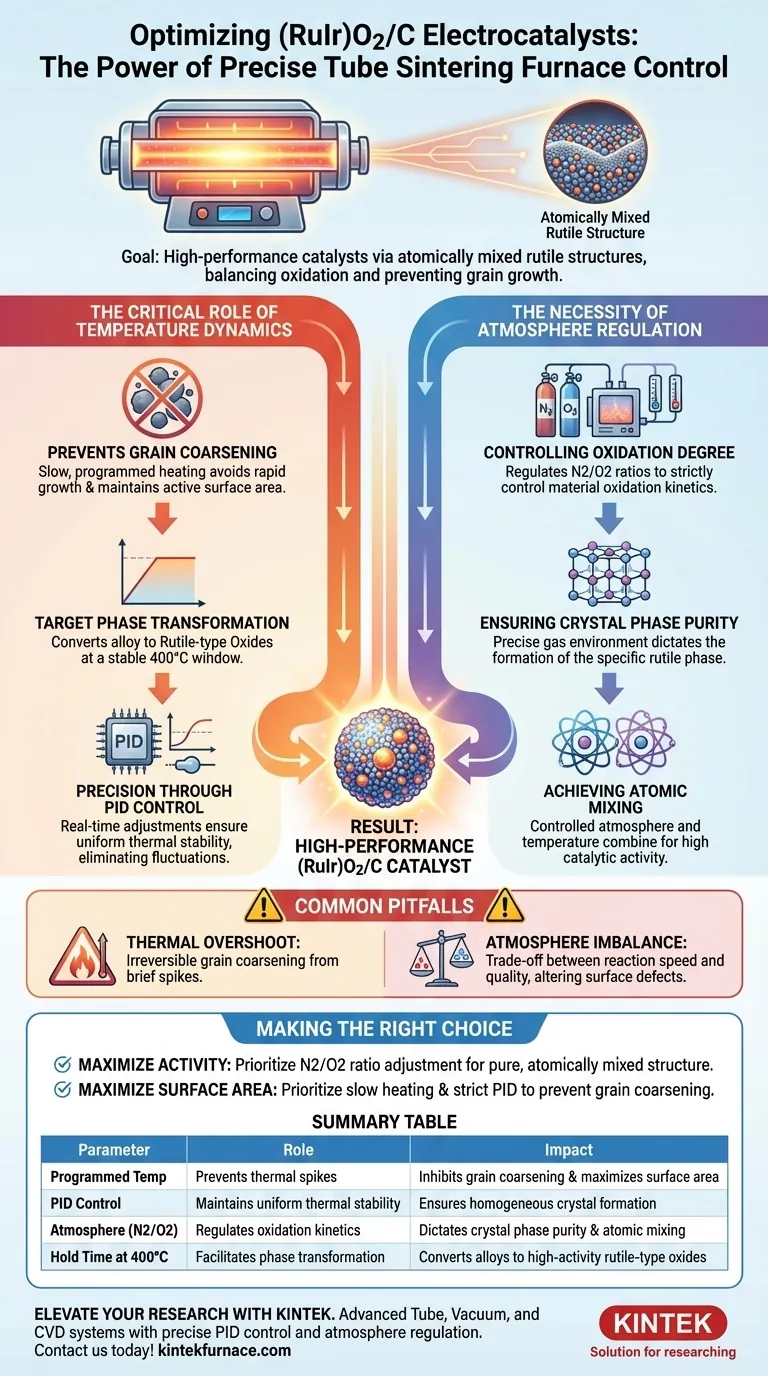

Optimizing the electrochemical performance of (RuIr)O2/C catalysts relies fundamentally on the precise annealing environment provided by a tube sintering furnace. Precise programmed temperature control prevents rapid thermal spikes that cause grain coarsening, ensuring the RuIr alloys slowly convert to rutile-type oxides, while atmosphere regulation (specifically N2/O2 ratios) dictates the oxidation degree and crystal phase purity required for high catalytic activity.

The key to high-performance electrocatalysts lies in achieving an atomically mixed rutile structure without increasing particle size. The tube furnace acts as a precision instrument to balance full oxidation against the risk of grain growth.

The Critical Role of Temperature Dynamics

Preventing Grain Coarsening

The primary chemical risk during annealing is grain coarsening, where small particles merge into larger ones. This process reduces the active surface area of the catalyst, significantly lowering its performance.

Programmed temperature control ensures that RuIr alloys are converted to oxides slowly and deliberately. By managing the heating rate, the furnace avoids "instantaneous high temperatures" that trigger rapid grain growth.

Target Phase Transformation

The specific goal is to convert the alloy into rutile-type oxides. This transformation must occur within a stable thermal window, specifically identified as a 400 °C environment in your primary protocol.

Precision Through PID Control

To maintain this stability, modern tube furnaces utilize PID (Proportional-Integral-Derivative) algorithms. This system continuously adjusts heating power based on real-time data from high-precision sensors (like K-type thermocouples).

This technology ensures the temperature remains uniform throughout the holding time. It eliminates thermal fluctuations that could lead to heterogeneous crystal formation.

The Necessity of Atmosphere Regulation

Controlling Oxidation Degree

Temperature alone is insufficient; the chemical environment is equally critical. You must regulate the flow ratios of Nitrogen (N2) and Oxygen (O2) inside the tube.

By adjusting these ratios, you strictly control the oxidation degree of the material. This prevents under-oxidation (leaving unstable metallic phases) or uncontrolled oxidation kinetics.

Ensuring Crystal Phase Purity

The interaction between the controlled atmosphere and the RuIr precursor dictates crystal phase purity. Precise gas regulation ensures the formation of the specific rutile phase required for the catalyst.

Achieving Atomic Mixing

The ultimate objective of combining temperature and atmosphere control is an atomically mixed (RuIr)O2 structure. This specific structural arrangement is directly responsible for the material's high catalytic activity.

Common Pitfalls and Trade-offs

The Risk of Thermal Overshoot

Without a programmed heating rate, furnaces can "overshoot" the target temperature. Even a brief spike above the target window can irreversibly coarsen the catalyst grains.

Atmosphere Imbalance

Failing to precisely meter the N2/O2 ratio creates a trade-off between reaction speed and quality. An atmosphere that is too oxygen-rich may accelerate the process but can alter the surface defects needed for catalysis.

Making the Right Choice for Your Goal

To maximize the potential of your (RuIr)O2/C electrocatalyst, apply these control principles based on your specific synthesis targets:

- If your primary focus is maximizing catalytic activity: Prioritize the precise adjustment of N2/O2 flow ratios to ensure the formation of a pure, atomically mixed rutile structure.

- If your primary focus is maximizing surface area: Prioritize slow, programmed heating rates and strict PID control to prevent thermal spikes and inhibit grain coarsening.

Success in catalyst preparation is not just about reaching a temperature, but about controlling the path the material takes to get there.

Summary Table:

| Parameter | Role in Catalyst Preparation | Impact on (RuIr)O2/C |

|---|---|---|

| Programmed Temp | Prevents rapid thermal spikes | Inhibits grain coarsening & maximizes surface area |

| PID Control | Maintains uniform thermal stability | Ensures homogeneous crystal formation |

| Atmosphere (N2/O2) | Regulates oxidation kinetics | Dictates crystal phase purity & atomic mixing |

| Hold Time at 400°C | Facilitates phase transformation | Converts alloys to high-activity rutile-type oxides |

Elevate Your Electrocatalyst Research with KINTEK

Precision is the difference between a high-performance catalyst and a failed experiment. KINTEK provides industry-leading Tube, Vacuum, and CVD systems designed for the rigorous demands of material science. Our furnaces feature advanced PID programmed temperature control and integrated atmosphere regulation to help you achieve perfect crystal phase purity every time.

Whether you need customizable high-temp solutions or expert-backed manufacturing for your lab, KINTEK is your partner in innovation. Contact us today to find the perfect furnace for your research!

Visual Guide

References

- Yeji Park, Kwangyeol Lee. Atomic-level Ru-Ir mixing in rutile-type (RuIr)O2 for efficient and durable oxygen evolution catalysis. DOI: 10.1038/s41467-025-55910-1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What is the role of the tubular furnace annealing process in the synthesis of Si@SnO2? Achieve Precise Nanocoatings

- What are the primary functions of a high-precision tube resistance furnace? Optimize Chloride-Doped Composite Synthesis

- What role does a high-temperature tube furnace play in the pore expansion of porous graphene? Expert Material Engineering

- Why are vacuum-sealed high-purity fused quartz tubes utilized as reaction vessels for PTI/Cu complex synthesis?

- What is the importance of the calcination process using a tube resistance furnace? Optimize Boron Catalyst Activation

- What are the key application features of a fluidized bed vertical tube furnace? Boost Efficiency and Uniformity

- How is the quartz tube furnace constructed for vacuum operations? Discover Key Design Elements for High-Temperature Vacuum Processing

- What is the purpose of a two-zone tube furnace for nanoparticle selenization? Achieve Precision Vapor Control