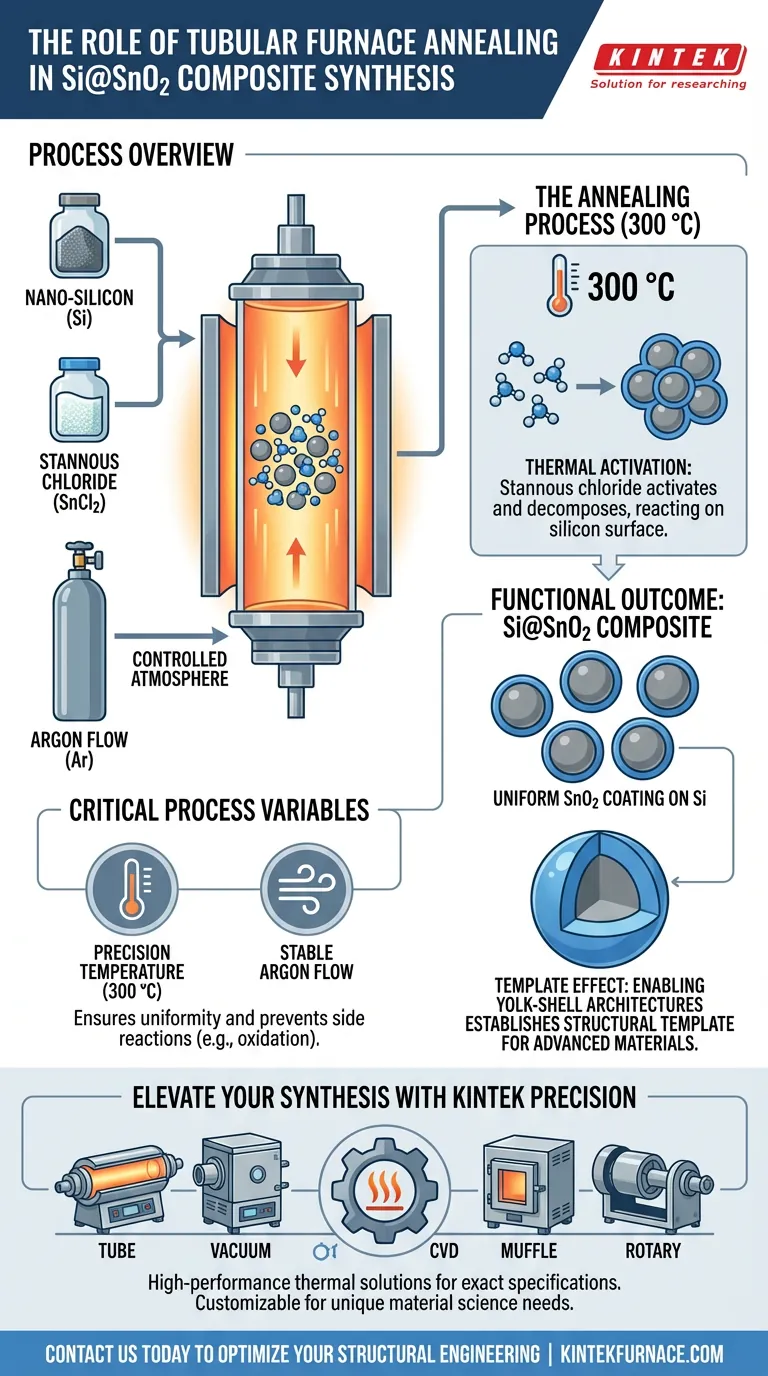

The tubular furnace acts as the critical reaction chamber for the thermal treatment of nano-silicon and stannous chloride. It maintains a specific temperature of 300 °C under a controlled argon flow to drive the chemical reaction. This process is responsible for depositing a uniform tin dioxide (SnO2) layer onto the silicon particles.

The annealing process is the foundational step for structural engineering in this composite. It transforms raw precursors into a uniform SnO2 coating, establishing the essential template required to construct advanced yolk-shell structures.

The Mechanics of the Annealing Process

Creating a Controlled Environment

The tubular furnace is utilized primarily for its ability to maintain a stable, inert atmosphere.

By introducing a controlled argon flow, the furnace prevents unwanted side reactions (such as oxidation from air) during the heating phase.

Thermal Activation of Precursors

The process involves heating a physical mixture of nano-silicon and stannous chloride to a precise target of 300 °C.

This thermal energy is necessary to activate the stannous chloride and initiate its decomposition or reaction on the silicon surface.

Functional Outcome: The Template Effect

Formation of Uniform Coatings

The primary output of this annealing step is the creation of a Si@SnO2 composite.

The furnace ensures that the SnO2 layer forms uniformly across the surface of the nano-silicon particles, rather than aggregating randomly.

Enabling Yolk-Shell Architectures

This specific coating process is not the final stage, but rather a preparatory one.

The uniform SnO2 layer serves as a structural template. This template is the prerequisite for the subsequent synthesis steps that generate "yolk-shell" structures, which are highly valued for their ability to accommodate volume expansion in materials.

Critical Process Variables

The Importance of Precision

While the chemistry is straightforward, the success of the synthesis relies heavily on the stability provided by the tubular furnace.

If the argon flow is inconsistent or the temperature deviates from 300 °C, the coating may fail to achieve the necessary uniformity.

Dependency on the Vessel

The choice of a tubular furnace is deliberate to ensure the precursors are heated evenly within the gas flow.

Without this specific setup, establishing the consistent template required for the yolk-shell architecture would be significantly more difficult.

Implications for Material Design

To maximize the effectiveness of this synthesis method, consider the following applications:

- If your primary focus is Uniformity: Ensure the tubular furnace maintains a steady argon flow to guarantee a consistent SnO2 shell thickness.

- If your primary focus is Structural Complexity: View this annealing step as the critical "templating" phase that dictates the quality of the final yolk-shell geometry.

The tubular furnace provides the controlled precision necessary to turn simple mixtures into engineered composite templates.

Summary Table:

| Process Parameter | Requirement | Role in Synthesis |

|---|---|---|

| Equipment | Tubular Furnace | Provides stable, controlled reaction chamber |

| Temperature | 300 °C | Thermally activates stannous chloride precursors |

| Atmosphere | Argon Flow | Prevents oxidation and ensures chemical purity |

| Core Output | Si@SnO2 Composite | Acts as a structural template for yolk-shell designs |

Elevate Your Composite Synthesis with KINTEK Precision

Uniformity and precision are non-negotiable when engineering advanced yolk-shell architectures like Si@SnO2. KINTEK provides the high-performance thermal solutions needed to ensure every annealing cycle meets your exact specifications.

Backed by expert R&D and world-class manufacturing, we offer specialized Tube, Vacuum, and CVD systems—alongside our full range of Muffle and Rotary lab furnaces—all of which are fully customizable for your unique material science needs.

Ready to optimize your structural engineering? Contact us today to discover how KINTEK’s advanced heating technology can bring consistency and quality to your laboratory research.

Visual Guide

References

- Jinhuan Li, Haiyong He. Simple and Safe Synthesis of Yolk-Shell-Structured Silicon/Carbon Composites with Enhanced Electrochemical Properties. DOI: 10.3390/molecules29061301

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- Why is thermal uniformity a significant advantage of tube furnaces? Achieve Consistent Heating for Precision Processes

- What safety measures should be followed when operating a split tube furnace? Ensure Safe and Efficient Lab Operations

- How does the environmental control of a high-temperature tube furnace affect the calcination of alpha-MoO3 powder?

- What is a high temperature tube furnace? Achieve Precise Heat and Atmosphere Control

- What role does a Tube Furnace play in the CVD growth of carbon nanotubes? Achieve High-Purity CNT Synthesis

- How is the high-temperature environment of a tube furnace used for adsorbent regeneration? Achieve Precise Recovery

- Why is a tube furnace with precise temperature control necessary for Fe7S8@CT-NS composites? Master Advanced Synthesis

- What is the core function of a vacuum atmosphere tube furnace when studying the evaporation and condensation behavior of metallic magnesium?