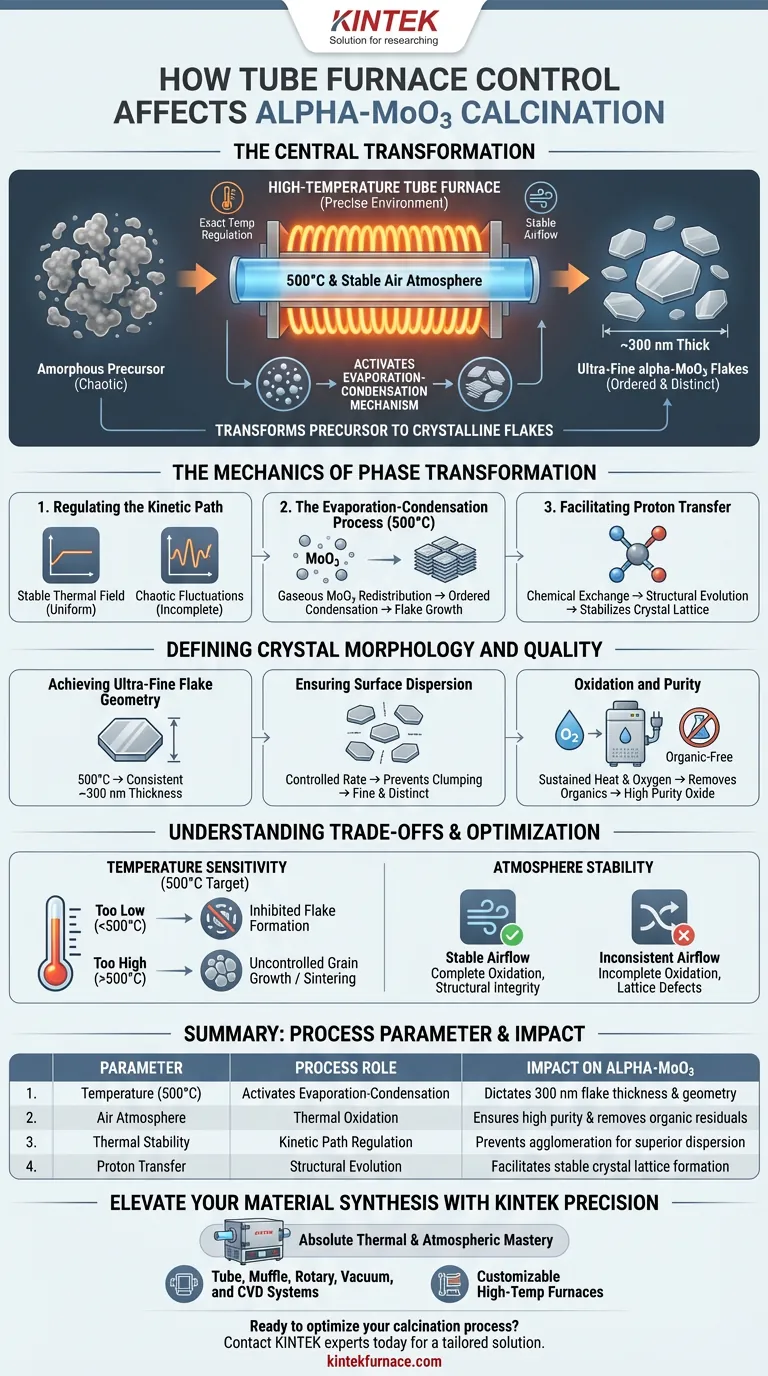

Precise environmental control within a high-temperature tube furnace is the determining factor in defining the final geometry and purity of ultra-fine flake alpha-MoO3 powder.

By maintaining a stable air atmosphere and exact temperature regulation, the furnace ensures the molybdenum oxide precursor adheres to a preset kinetic path. Specifically, at a calcination temperature of 500°C, this environment drives proton transfer and an evaporation-condensation mechanism, resulting in well-dispersed flake crystals approximately 300 nm thick.

Core Takeaway The tube furnace does not merely heat the material; it creates a specific thermodynamic environment that activates the evaporation-condensation growth mechanism. This control is essential for transforming amorphous precursors into distinct, ultra-fine crystalline flakes rather than irregular or agglomerated particles.

The Mechanics of Phase Transformation

Regulating the Kinetic Path

The primary role of the tube furnace is to enforce a specific "kinetic path" for the material.

Rather than subjecting the precursor to chaotic thermal fluctuations, the furnace provides a stable thermal field. This ensures the transformation from precursor to alpha-MoO3 is complete and uniform throughout the batch.

The Evaporation-Condensation Process

At the critical temperature of 500°C, the furnace environment facilitates a unique growth phenomenon known as evaporation-condensation.

This mechanism allows gaseous MoO3 species to redistribute and condense in an ordered manner. It is this specific physical process that directs the material to grow into flake-like structures rather than spherical particles.

Facilitating Proton Transfer

The thermal environment within the tube is tuned to promote proton transfer during the calcination stage.

This chemical exchange is a fundamental driver for the structural evolution of the oxide. It works in tandem with the thermal energy to stabilize the final crystal lattice.

Defining Crystal Morphology and Quality

Achieving Ultra-Fine Flake Geometry

The interaction between the air atmosphere and the 500°C thermal setpoint directly dictates the dimensional properties of the powder.

Under these conditions, the crystals grow into ultra-fine flakes with a consistent thickness of approximately 300 nm. Deviating from these environmental controls would likely result in altered dimensions or inhibited flake formation.

Ensuring Surface Dispersion

A critical output of this specific environmental control is the "excellent surface dispersion" of the final particles.

By controlling the rate of the evaporation-condensation process, the furnace prevents the particles from fusing into large, unusable clumps. This ensures the final powder remains fine and distinct.

Oxidation and Purity

While the primary focus is on morphology, the continuous high-temperature air environment also serves a purification function.

The sustained heat and oxygen supply facilitate the thermal oxidation of precursors. This ensures that any residual organic components are effectively removed, securing the high purity of the final oxide powder.

Understanding the Trade-offs

Temperature Sensitivity

The mechanism described is highly specific to the 500°C operating point.

If the temperature drops significantly below this threshold, the evaporation-condensation mechanism may not activate, preventing flake formation. Conversely, excessive heat could lead to uncontrolled grain growth or sintering, destroying the ultra-fine nature of the particles.

Atmosphere Stability

The process relies on a stable air atmosphere to maintain the oxidation state of the molybdenum.

Inconsistent airflow or atmospheric composition can disrupt the phase transition. This could lead to incomplete oxidation or the formation of lattice defects that compromise the material's structural integrity.

Making the Right Choice for Your Goal

To optimize the production of alpha-MoO3, you must align your furnace settings with your specific material requirements.

- If your primary focus is Morphology (Flake Shape): Strictly maintain the temperature at 500°C to ensure the proton transfer and evaporation-condensation mechanisms are active.

- If your primary focus is Purity: Ensure the air atmosphere is continuous and stable to fully oxidize precursors and vent volatile organics.

- If your primary focus is Dispersion: Prioritize the stability of the thermal field to prevent hot spots that cause particle agglomeration.

The precise control of the tube furnace transforms calcination from a simple heating step into a sophisticated crystal engineering process.

Summary Table:

| Parameter | Process Role | Impact on alpha-MoO3 |

|---|---|---|

| Temperature (500°C) | Activates Evaporation-Condensation | Dictates 300 nm flake thickness & geometry |

| Air Atmosphere | Thermal Oxidation | Ensures high purity & removes organic residuals |

| Thermal Stability | Kinetic Path Regulation | Prevents agglomeration for superior dispersion |

| Proton Transfer | Structural Evolution | Facilitates stable crystal lattice formation |

Elevate Your Material Synthesis with KINTEK Precision

Achieving the exact 300 nm flake morphology for alpha-MoO3 requires more than just heat—it requires absolute thermal and atmospheric mastery.

Backed by expert R&D and manufacturing, KINTEK offers high-performance Tube, Muffle, Rotary, Vacuum, and CVD systems designed to give you total control over your kinetic paths. Whether you need a standard setup or a fully customizable high-temp furnace for unique research needs, our engineering team ensures your lab achieves maximum purity and consistent crystal geometry.

Ready to optimize your calcination process?

Contact KINTEK experts today for a tailored solution

Visual Guide

References

- Xiao Zhang, Hang Qu. Investigation on the Thermal Decomposition Behavior of Molybdenum Trioxide Precursor. DOI: 10.3390/ma18010165

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What are the maintenance requirements for a horizontal electric furnace? Ensure Peak Performance and Longevity

- What is the role of an inert gas protection tube furnace in hardening High Vanadium HSS? Achieve Precision Hardness

- What are the advantages of using a fixed-bed continuous flow tube reaction system? Unlock Precision CO2 Hydrogenation

- What is the primary function of a quartz tube diffusion furnace? Optimize PERT Solar Cell Doping Performance

- What is the purpose of introducing high-purity nitrogen into a tube furnace? Enhance Biomass Torrefaction Efficiency

- What is the necessity of using sealed silica tubes in the BCM reduction method? Ensuring High-Purity Synthesis

- How does a tube reduction furnace simulate a blast furnace? Precision Testing for Metallurgical Performance

- What is the purpose of using an industrial-grade tube furnace for the heat treatment of copper hydroxide precursors?